Vertical Two Tie-Bar Injection Molding Machine

产品分类 : 液压夹模注塑机

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production, then reduce the cost of production. High precision mold platen (Parallelism/flatness:0.01/100mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact, space-saving design, reduce the heavy burden of the floor of factory.

Vertical Single Shuttle Table Injection Machine

产品分类 : 立式注塑机

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

Vertical Shuttle Table Injection Molding Machine

产品分类 : 立式注塑机

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie-bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

Custom Vertical LIM LSR Injection Moulding Machine

产品分类 : 立式注塑机

Precision vertical clamping system (parallelism/ flatness : 0.02/100mm) , heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life. Increased productivity and efficiency with shuttle table or rotary table configuration. Pick and place products while another product finsihes molding. Energy savings of around 50-70% with servo pump power system. Safety cover, Light curtain, pneumatic door and dual palm safety button for personnel safeguard. Multi-Language PC Base industrial type Linux core system. 1000 sets of mold settings can be stored and export as backup. Complete record of history settings & warnings. Built in USB connect. On-line remote control and maintenance service.

Vertical 4-TIE BAR Injection Machine

产品分类 : 液压夹模注塑机

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.01/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

C Type Injection Molding Machine

产品分类 : 立式注塑机

Tie-bar less (C type) design gives more space for operation. Especially suitable for the power cord and connector with wire. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , thus reduce the cost of production. High precision mold platen ( Parallelism/ flatness : 0.01/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitrite and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, resolve the floor space shortage problem of factory. Material injected through parting line to cavities.

LDPE超高速吹膜机

产品分类 : 吹膜挤出机

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

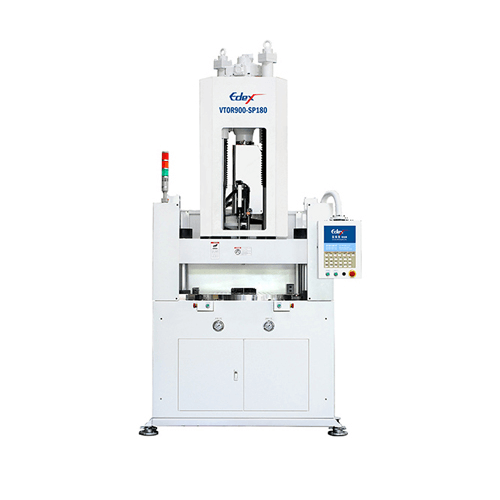

VTOR 系列精密立式转盘射出机

产品分类 : 自动注塑机

● 创新设计转盘面积最小,容模尺寸最大● 可搭配柱塞式或螺杆式射出● 专利设计辅助进料系统,贮料跟卧式机一样精准● 两板直压式四缸锁模机构● 专利辐射式力学范本耐用30年● 安全光栅保护装置● 智慧程式控制系统让射出更容易● 相对同规格机型,机台高度低● 符合人体工学的工作台高度● 电脑控温气冷式油冷却系统● 精密节能油电伺服系统

立式电动射出机-YE-50V

产品分类 : 立式注塑机

A number of patented electric injection device Precision electric injection function Precision electric metering function Electric pedestal does not slide function Energy-saving hydraulic servo mold clamping function Accurate low pressure off mode protection function Energy-saving hydraulic servo thimble function Template rust plating processing Template parallelism fine tuning function Template low-top design With 8 T-groove, easy to fix the mold Thick template with high tensile guide posts Configuration template guide column anti-drip bumper sleeve Configure mechanical closing safety bars Configure mechanical shut-off safety electrical protection Open all the safety gates to stop the design Configuration key type safety door safety switch Configuration rail horizontal operation safety gate design Injection device can be flipped to maintain the factory accuracy to reduce the height of the handling method Injection closed loop feedback function Holding pressure switching point accuracy of 0.01mm Packing pressure accuracy of up to 0.1% High-speed rigid filling, to eliminate floating phenomenon Prevent the drawing function A variety of peripheral equipment chain function Equipped with peripheral equipment power outlet With robot centralized terminal block Hopper holder moving function Equipped with resin feed tube holder Equipped with adjustable height white iron trough Equipped with a perspective control water divider Equipped with cooling water quick connector The machine is neat and without any pipe exposure Than the same level of oil-saving 25% to 60% Than the same level oil machine to save cooling water 70% Equipped with 10.4 "color touch screen PID automatic temperature adjustment function Japan's Mitsubishi control system Equipped with wear-resistant material pipe