收缩标签机

收缩标签机用于将热收缩套标精准套于瓶装或罐装容器表面,经由蒸汽或热风收缩后紧密贴合,具备防伪、美观、品牌识别等包装优势,广泛用于饮料、洗护、保健品等领域。

PRM-Taiwan 提供高效的收缩标签与套标设备,支持高速贴标、裁切与热缩整合,可接入灌装、封口产线以提升包装效率。

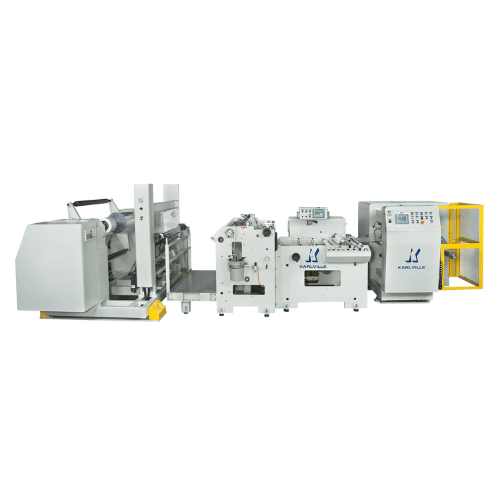

合掌机K3 Plus

产品分类 : 收缩标签和袖子

Unwind Edge Guide System Independent Unwind, Forming and Rewind Tension Zones Frictionless Forming System Automatic Layflat Set-up Automatic Layflat Correction Direct Injection Solvent...

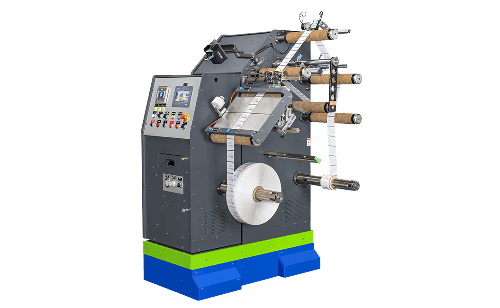

标签检品复卷机(正反转) - FSP-250-2

产品分类 : 收缩标签和袖子

高速、正反转、大规格、多用途、全新一代正反转检品复卷机专为各种标签及膜卷之品质检验及复卷需求所设计;放、收卷采马达控制配备多点记忆反转功能,作业中可切换运转方向且张力稳定。无论是进行印刷检查、膜面...

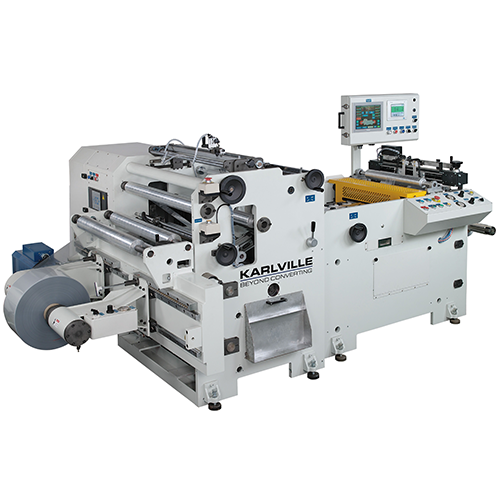

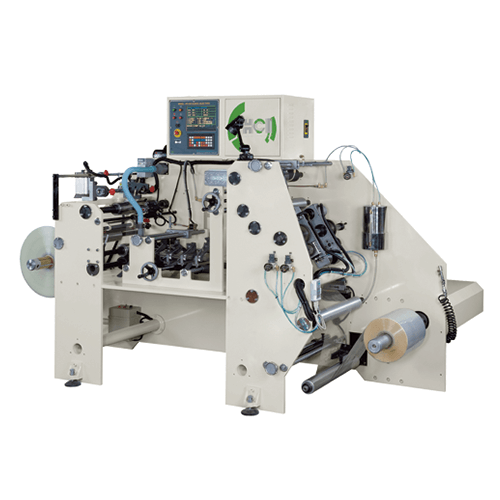

收缩标签高速黏合机-FP250

产品分类 : 收缩标签和袖子

专为各种收缩标签如PVC、PS、PET、POF等材料之管状成型及中间黏合所设计;本高速黏合机放、收料皆采悬臂式设计配合坚固之机台结构可高速生产收缩标签。

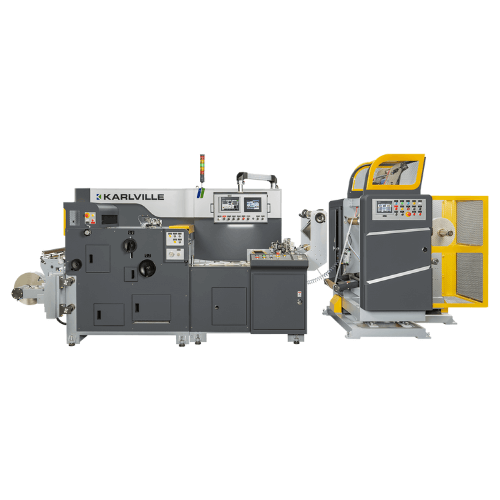

Seaming Machines K5 Plus

产品分类 : 收缩标签和袖子

The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. This new patented design makes the K5 PL...

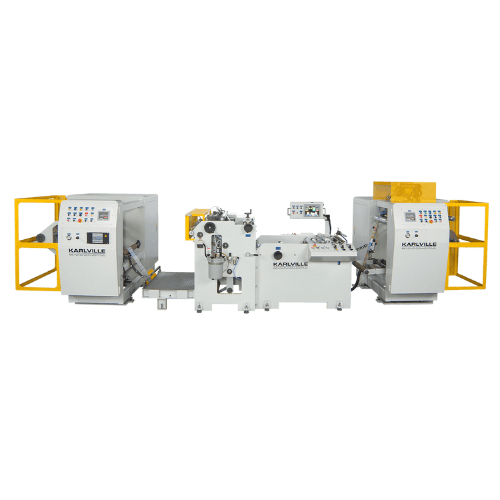

FP-X 双收料粘粘合机

产品分类 : 收缩标签和袖子

华周工业新一代FP-X双收收料标签高速粘合机,满足高速生产、自动换卷和线上检测的要求。 接料、标签宽度测量以及溶剂检测系统,为粘合与产品二检测系统合一开发。

收缩标签黏合机-FK Series

产品分类 : 收缩标签和袖子

本机专为生产PVC彩色收缩标签之中间黏合所设计,操作简便维护容易。配合FSC系列封剪机完美完成制袋,此收缩标签黏合机为最经济之投资项目。

标签检品复卷机(正反转)FSP-250-2

产品分类 : 收缩标签和袖子

专为各种标签及膜卷之品质检验及复卷需求所设计;放、收卷采马达控制配备多点记忆反转功能,作业中可切换运转方向且张力稳定。无论是进行印刷检查、膜面检查或是收缩标签黏合品质检验皆可操作自如。

高效率经济型分条机- Enova 系列

产品分类 : 收缩标签机

适用材料: OPP,PET,CPP,PVC(硬质),PP收缩膜,纸,离型纸,电镀纸,铝箔纸,玻璃纸,自粘商标纸,铝箔,铜箔,碳带,不织布,缎带。

POF Heat Shrink Film

产品分类 : 收缩标签机

POF heat shrinkable film is an environmentally friendly shrink film, Multi-layer co-extrusion. It can be in direct contact with food. Benison provides single-wound and center folded materials, whic...

Auto Shrinkable Sleeve Machine-GSL-600

产品分类 : 收缩标签机

Suitable applications:For label insertion on containers of sundries, food,beverage, dairy products, and wine, medicines, and industrial products. Model : GSL-600