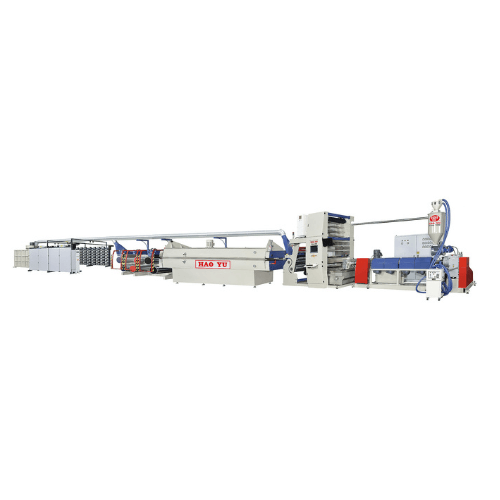

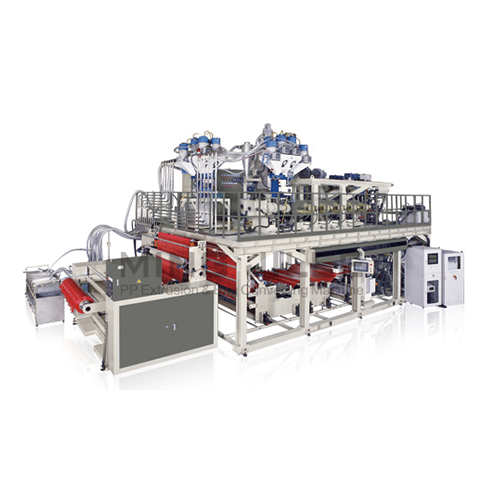

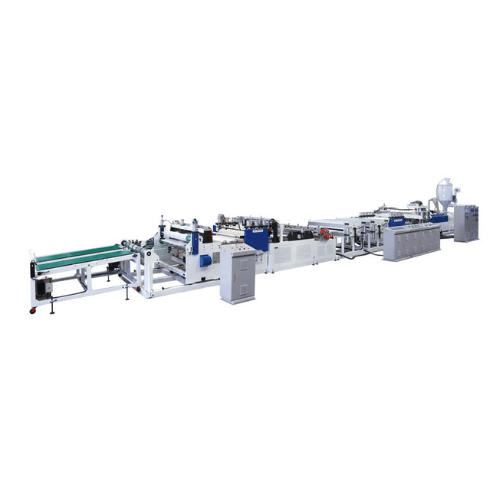

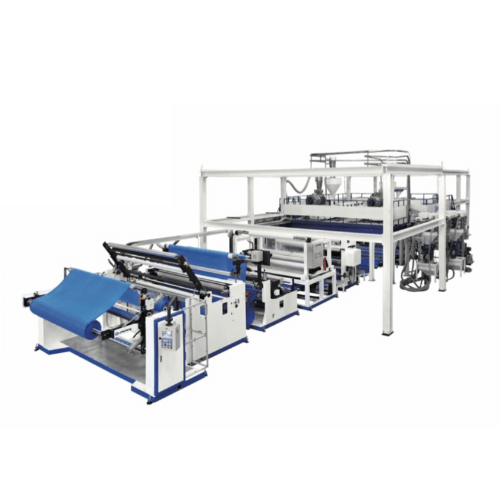

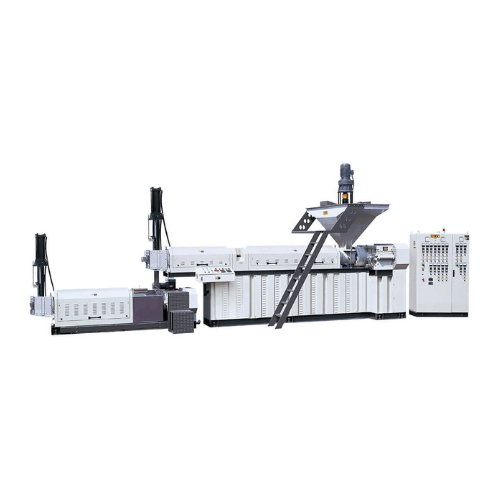

Co-Extrusion Two Layer HIPS/GPPS Sheet Extrusion Machine

产品分类 : 薄膜和片材挤出生产线

Co-Extrusion Two Layer HIPS/GPPS Sheet Extrusion Machine

板材押出生产线

产品分类 : 薄膜和片材挤出生产线

单层和多层板材生产系统的最多达5层 灵活可靠的下游设备 完整的板材押出生产线含55-200mm的押出机 加工能力:ABS, PE, PP, PS, PET, PC, PMMA, 和其他热塑性材料

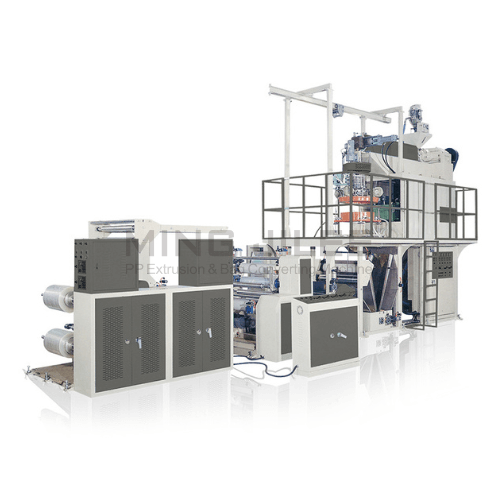

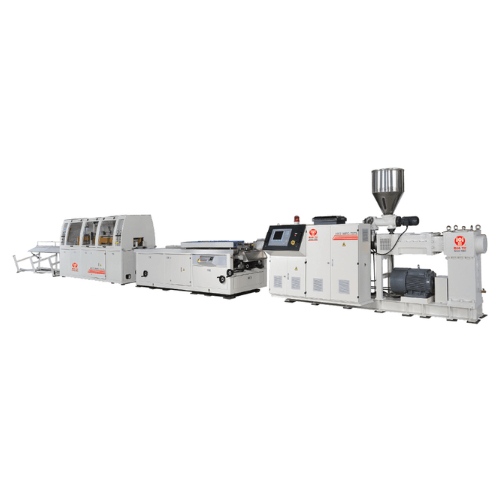

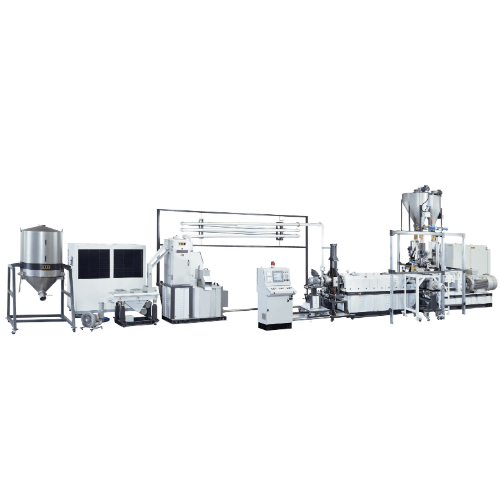

PP板材押出生产线

产品分类 : 薄膜和片材挤出生产线

Mono layer & Multi-layer Sheet Extrusion Systems for up to 5 layers. Versatile & reliable downstream equipment.Complete Sheet Extrusion Line with extruders from 55-250mm. Processing Capabilities: ABS, PE, PP, HI/PS, PET, PC, PMMA and other thermoplastic materials.

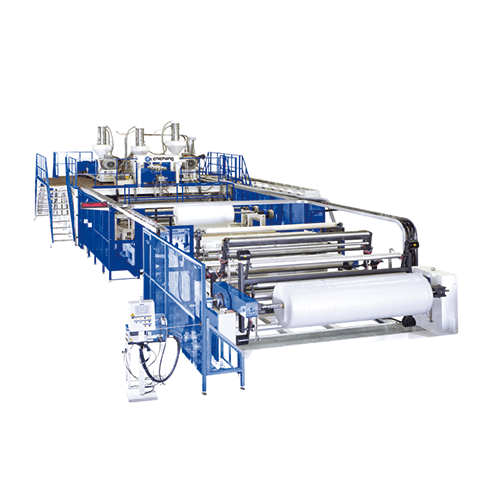

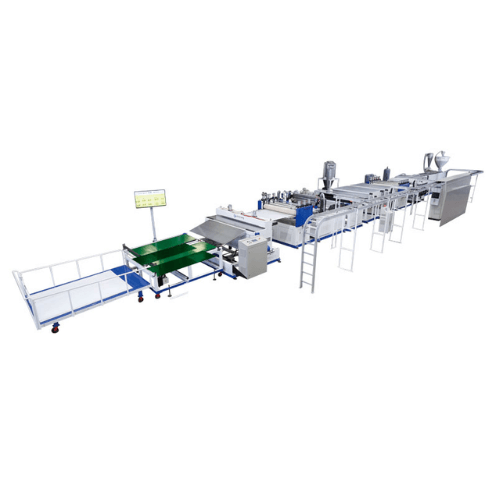

2400mm PP / PC中空板材押出生产线

产品分类 : 薄膜和片材挤出生产线

For 47 years, Chi Chang has been designed and manufacturing fully computerised lines for sheet & film extrusion and co-extrusion. Our highly qualified team of engineers, operators and technicans has always been searching for high extrusion technology to meet your requirements. After years reserching since our first PP hollow profile sheet extrusion line in 1987, our new generation will produce PP hollow profile sheet with width from 1200mm to 2500mm, thickness from 2mm to 10mm and output upto 500 kg/hr. In the mean time, we are pleased to introduce our new PC hollow profile sheet extrusion line. It is able to produce two-layer and three-layer PC hollow profile sheet with width 1200mm & 2100mm and thickness 5mm-10mm (two-layer) and 16mm (three-layer), and output upto 500 kg/hr.

RePet Wood WPC型材挤出生产线

产品分类 : 管材与型材挤出生產线

Green products 100% recyclable & reusable Waterproof / Insetct proof / Anti corrosion Long term service Wood appearance Customization

PP/PC中空板材押出生产线

产品分类 : 薄膜和片材挤出生产线

40年来,增昌致力于设计和制造的全电脑床板材及薄膜押出和共押出。我们由工程师,机器操作人员和技术人员所组成的高素质团队不断的在追求高阶押出技术,以满足您的需求。经过多年自从我们于1987年研发第一条PP中空型材押出机生产线,我们新一代的产线将生产宽度1200mm到2500mm的PP中空板材,厚度从2mm到10mm,产量每小时高达500公斤。同时,我们很高兴推出我们新的PC中空板押出生产线。它能够生产2层和3层的PC中空板, 宽度1200mm和2100mm,厚度5mm,10mm(2层)和16mm(3层)和每小时输出量高达500公斤。

平板压出机(平板押出机)

产品分类 : 薄膜和片材挤出生产线

• 平板压出整厂设备-- 平板压出机(平板押出机) • 塑胶平板押出机整厂设备 以控制箱觸控面板操作 主機速度依模頭壓力改變,出料穩定 由滾輪輸出維持平板平順 滾捲器有張力控制器和計碼器精準控制切割寬度 訂製機種

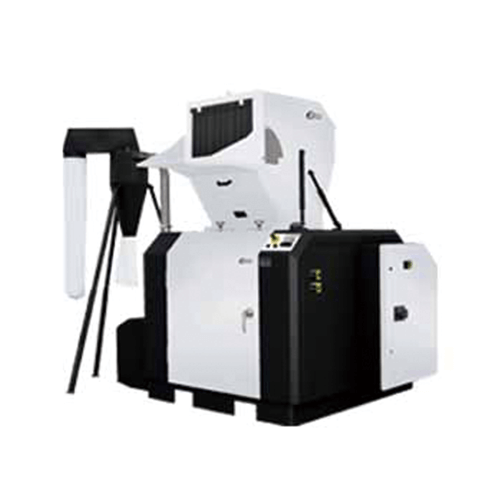

静音集中粉碎机SG-43-50-70

产品分类 : 造粒机

SG-43/50/70系列静音集中粉碎机适用于粉碎各种塑胶材料,包括注射成型、吹塑成型或挤出成型后产生废料的集中回收。 SG-43/50/70系列机型结构坚实,操作方便,换刀简便快捷;渐切式一体化动刀设计,使切削效果更好,噪音更低,同时也使能量损耗降到最小程度。

静音集中粉碎机SG-43

产品分类 : 造粒机

SG-43系列静音集中粉碎机适用于粉碎各种塑胶材料,包括注射成型、吹塑成型或挤出成型后产生废料的集中回收。 SG-43系列机型结构坚实,操作方便,换刀简便快捷;渐切式一体化动刀设计,使切削效果更好,噪音更低,同时也使能量损耗降到最小程度。

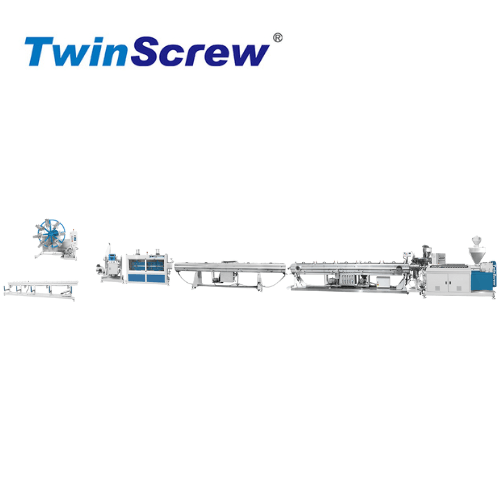

PVC塑料硬质管制造机

产品分类 : 管材与型材挤出生產线

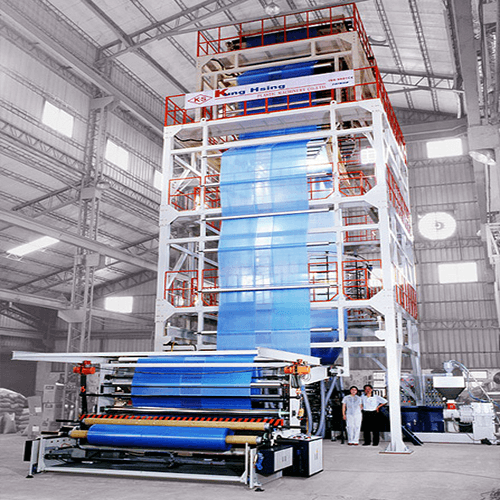

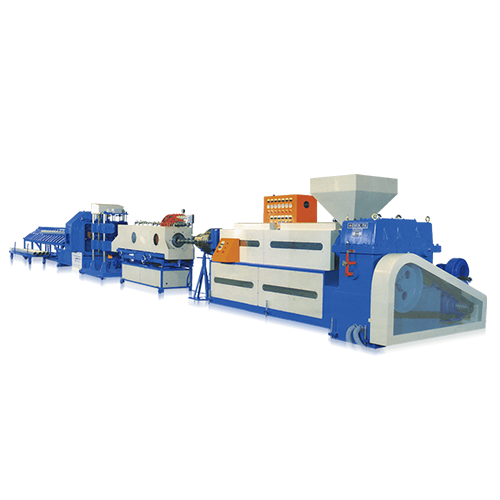

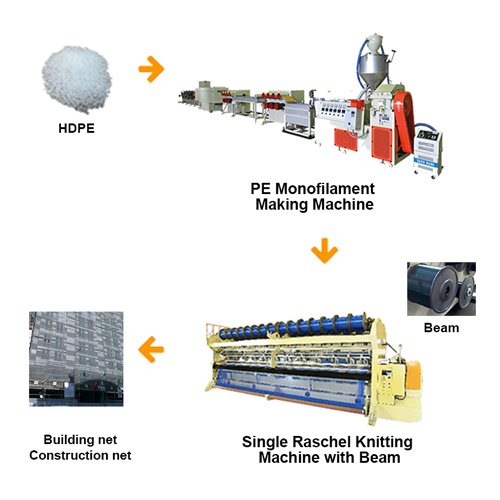

建筑防尘网

产品分类 : 工业针织机

This extrusion line is designed for making monofilament and suites for PE raw material. It can offer the round yarn (monofilament) to model SR-R & DR-R knitting machine. Model SR-R series is Single needle bed Raschel knitting machine which design for making the Round yarn (mono yarn) in all different kind of raw material, for example Nylon, PE, PP etc.

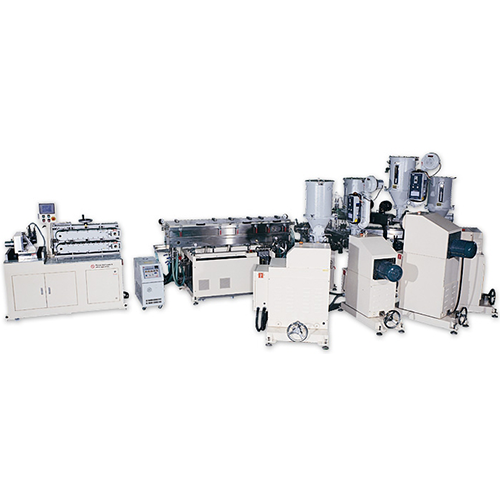

多层押出与切断机EDC-08-05

产品分类 : 切割机

Plastic material has its own characters. In co-extrusion system. We use and combine several kinds of materials, therefore, the characters of single layer tube can't compete with the complex characters of co-extrusion tube. Glossy surface (using: EVOH / RESIN / PE)Extensive color combination (using: PE + PEARL / PE + PIGMENT)Excellent barrier property (using: PE / TIE RESIN / EVOH / TIE RESIN / PE)Scratch and dust free (using: LDPE / LDPE / LLDPE)Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic... etc.

XPS板押出机生产线

产品分类 : 发泡挤出机

Excellent thermal insulation Very low water & humidity absorbance Very high compression strength Very high mechanical resistance Stability of dimension Homogeneous density Easy to transport, cut & apply And many more

粉碎机

产品分类 : 塑料破碎机

Our PVC crusher machine is an essential piece of auxiliary equipment for efficiently recycling and reducing waste material in PVC plastic wood composite profile extrusion lines. Designed for high output and reliability, this PVC crusher machine features robust blades and advanced crushing technology to handle various types of PVC and composite materials. This PVC crusher machine ensures uniform particle size and enhances material reusability, making it an ideal solution for optimizing production processes and minimizing waste in PVC crusher machine operations.

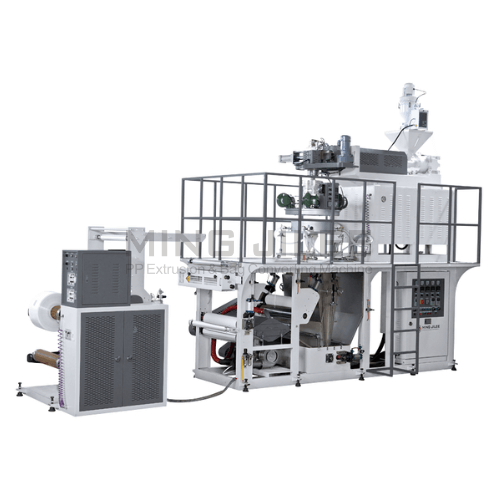

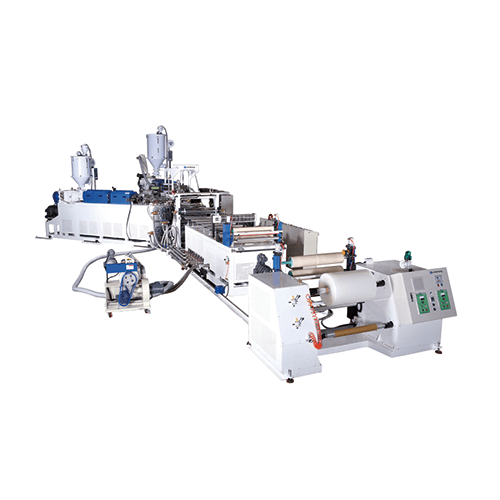

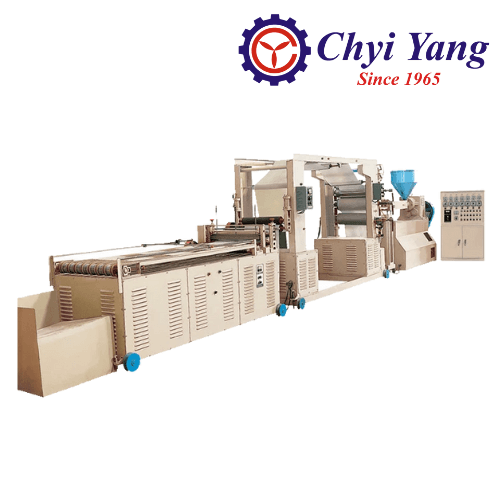

PE Foam & PE/PP Sheet Extrusion Line

产品分类 : 发泡挤出机

T-Die Extruder machine is equipped with cutter or winder to produce PP/PE sheets PP sheet is available in file cover, stationary etc. Film thickness 0.5~2.5 mm For different machines’ structure, can produce PE, PP sheet & PE foam sheet. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

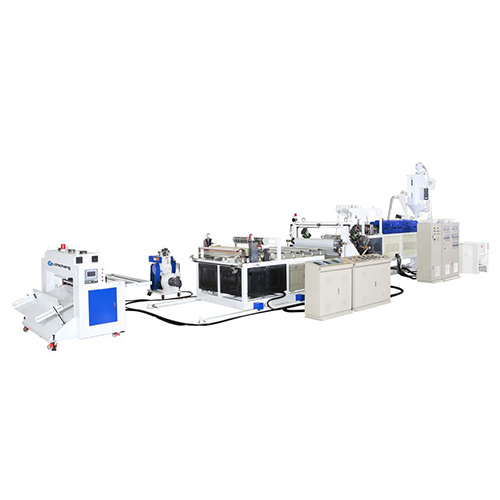

3层气泡膜押出生产线

产品分类 : 气泡膜/片材挤出机

The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive.Agricultural sector (green house) with anti-UV additive.Covering of swimming pool with anti-UV additive.Typical packaging with anti-shock, anti-abrasion and anti-crushing functions.Laminated with paper, PE woven and aluminum foil for making envelope.

2.5公尺宽,3层气泡膜押出(附2个卷曲机)

产品分类 : 气泡膜/片材挤出机

Various models to meet with your needs. Sheet width from 1,200MM to 2,500MM, from 2 layers to 10 layers. Tailored-made machine available.

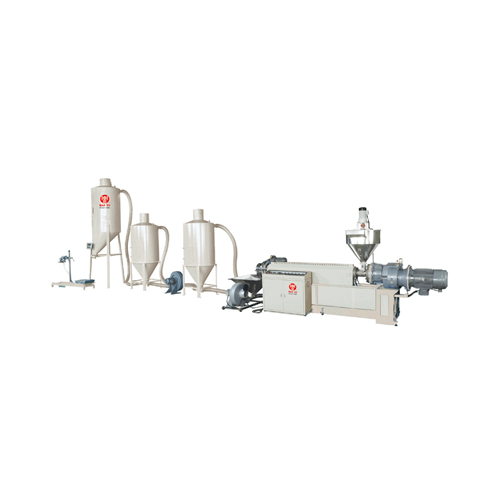

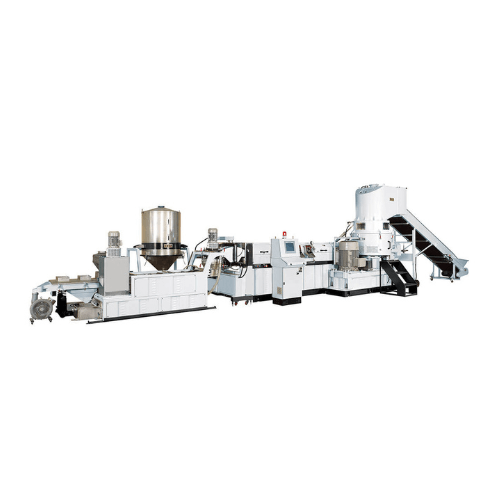

Side Force Feeder Type Recycling Pelletizing Extrusion Line | CK-SF

产品分类 : 塑料造粒机

CK-SF series Side Force Feeder Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic crushed films. Possible materials : EPE, EPP, EPS, PP, HDPE, LDPE, ABS, PS crushed films.

WPC PROFILE EXTRUSION LINE - PE/PP/PS/TPE/PVC

产品分类 : 管材与型材挤出生產线

The WPC profile extrusion line is a set of machines used in the production of WPC boards. Differences between WPC profile extrusion and general profile extrusion WPC profile extrusion machine is different from general profile extrusion machine, It has to maximize mixing while minimizing damage to the biomass furnish because the WPC material involves two different types of materials: wood and plastic. It is more accurate processing temperature, melt flow index, etc. are required. The same is that general profile extrusion is a process by which various plastic materials are used to develop quality plastic products that have a feature of continuous (ex: plastic board) but do not include sheet or film products. How does WPC profile extrusion line work? The process of WPC profile extrusion begins with the mixing of wood powder and plastic in the mixer. The ratio of wood powder to plastic varies depending on the desired strength and durability of the final product. Once the mixture is blended, it is fed into the conical twin-screw extruder. The extruder has two screws that rotate in opposite directions, pushing the mixture through a barrel and melting it. The molten mixture is then pushed through a die that determines the shape and size of the extruded profile. The extruded profile is then passed through the vacuum calibration table, which cools it and sets its shape. The haul-off machine pulls the profile through the calibration table, maintaining its shape and ensuring its dimensions are correct. The cutting machine cuts the profile to the desired length, and the stacker stacks the finished product. Advantages of WPC profile extrusion line Efficient and consistent production of high-quality WPC profile products. The extrusion process ensures that the final product has a uniform shape and size, with consistent mechanical properties. Highly automated, reducing the risk of human error and increasing efficiency. Cheng-Yu Plastic Machine is a professional WPC profile extrusion line manufacturer As demand for sustainable, eco-friendly products continues to grow, the wood-plastic composite (WPC) market is booming. We develop WPC profile extrusion lines for profile manufacturers who need a reliable, efficient, and high-quality production process. It is a versatile and flexible solution for profile manufacturers in various industries.

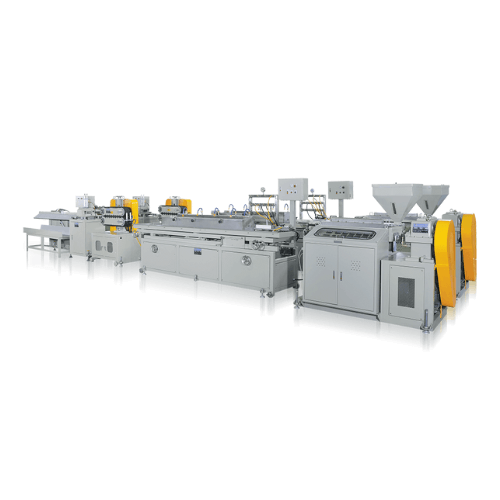

Side Shredding Type Recycling Pelletizing Extrusion Line | CK-SC

产品分类 : 塑料造粒机

CK-SC series Side Shredding Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic film, fiber, carpet, fabric, jumbo bag, etc. Possible materials : PP, HDPE, LDPE, PET, PC film, Nylon fiber, PP carpet, Jumbo bag, EPE, EPP, EPS, etc.

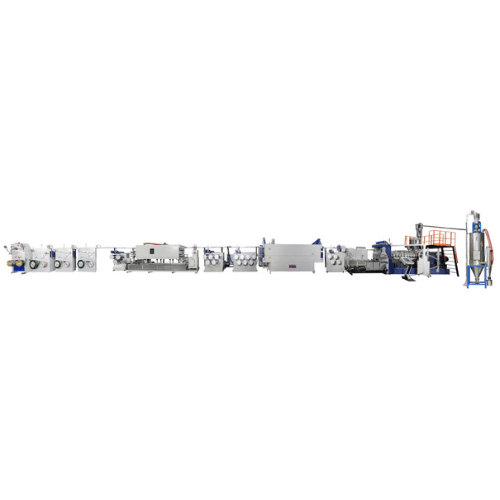

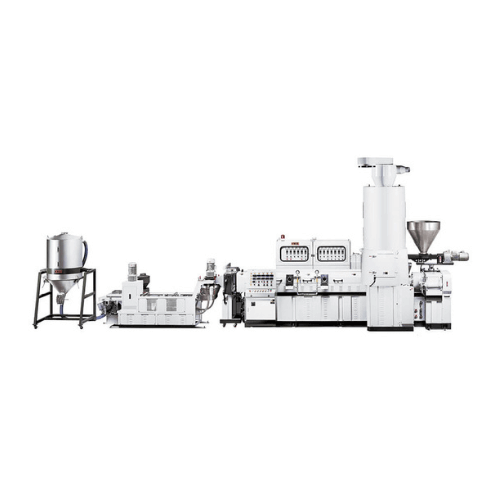

Double Section Recycling Pelletizing Extrusion Line | CK-HSD

产品分类 : 塑料造粒机

CK-HSD series Double Section Plastic Recycling Pelletizing Line is ideal for recycling dirty plastic flakes. Possible materials : PP, PE, ABS, PS, POM, PC, PA, PMMA, PBT, PET, etc.

Co-rotating Twin Screw Underwater Pelletizing Compounding Line | CK-HT

产品分类 : 双螺杆挤出机

CK-HT series Co-rotating Twin Screw Underwater Pelletizing Compounding Extrusion Line is designed especially for compounding materials with high viscosity, low MI, or difficulty to be shaped. The extrusion line can be applied to a wide range of materials and applications. Possible materials: TPU, TPE, TPV, TPR, PP, PS, PLA, PVA, SEBS, EVA, Rubber, Hot-melt adhesive, Special resin, and Micro pellet, etc.