空气填料机 (AL)

产品分类 : 装载机和输送机

光学级不锈钢材质,不卡料可避免污染,容易拆装清理。 玻璃窗口方便检查工作情况,安全警报装置让作业员无安全之虑。 体积小重量轻,可直接放置在成型机上,不需再另外添购自动填料机输送原料,节省空间与设备成本。 符合小批量多种类的生产,稳定性高,高效率输送可避免原料回潮之困扰。 采空气输送方式更有效率,无马达设计,低噪音,适合无尘室、室内与高精密的电子产业、医疗用塑料制品等对环境高规格要求产业使用。

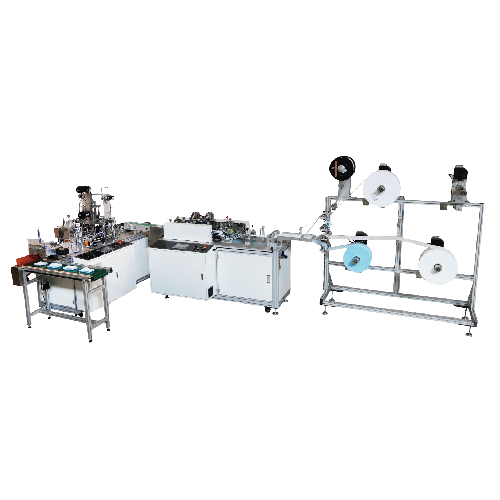

印刷定位平面口罩制造机

产品分类 : 制袋机按用途

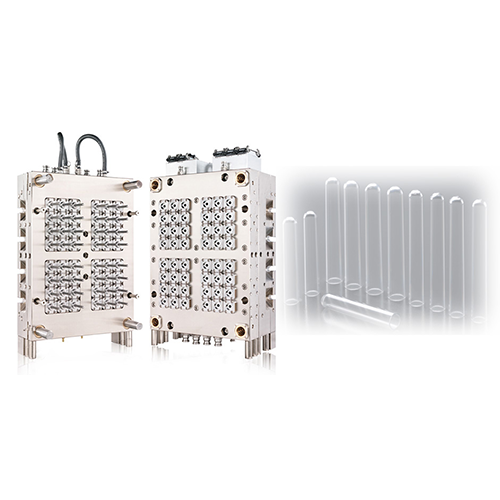

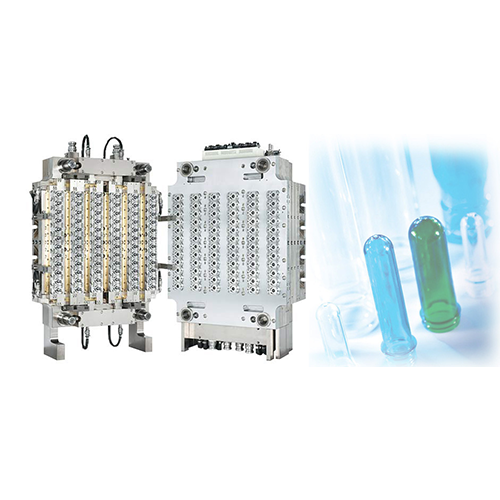

多模穴模具:热浇道控制器/ 温控器-TC5200

产品分类 : 热流道系统

本台TC5200多模穴模具用之「热浇道控制器、温控器」,单台温度控制组合可从26点至72点,甚至能多台连结至240点,且模组式的装置设计,使维护工作更加简便,其中由一段控制两点温度的优势,能大幅降低购置的成本。人机介面采用图像显示并可调整操作视角,可轻易上手完成多点控制,再加上RS485通讯功能,可一次设定多组控制进而简化操作程序,另附加实用的电流侦测指示功能等。本TC5200 多模穴模具用之「热浇道控制器、温控器」特别适用于汽车业、瓶胚射出、医疗耗材等,有效控制高成本原料之使用,实现未来一站式生产控制,将为业界带来更多的利益。长新

电晕静电驻极设备

产品分类 : 无纺布生产线

This CORONA ELECTROSTATIC TREATER is used to turn materials such as melt-blown fabric (face mask sheet),non-woven fabric (non-woven sheet) and polymers into electrets. The equipment includes a high-frequency inverter power supply, special electrodes and rollers. Through the mutual control of these components, the electret material can deeply capture the charge energy, and maintaining the polarization for a long period. This equipment can be used for application such as turning melt-blown fabric, non-woven fabric (non-woven fabric) and air filter into electret. It greatly increases the filtration efficiency of the filter material by capturing tiny particle which is smaller than filter density. More importantly, this CORONA ELECTROSTATIC TREATER helps melt blown fabric increase 45~65% of filtration efficiency and turns it to the most important layer for medical face mask such as N95, KN95 etc. to reduce infected by corona virus COVID-19. Note: An electret is a material that almost remains electric polarization permanently and is able to generate an electric field in the surrounding area. The electret strength will last longer when corona electrostatic charges deeply by high voltage and frequency.

Multi Layer 系列

产品分类 : 电动中空成型机

-VS系列:可增加一条透明白线于容器侧边,可方便看到内容物存量,如机-TC系列:适合生产双色之塑胶容器或玩具。 -TL系列:用以生产双层之容器,可节省高价材质用量,一般常用于化妆品或洗发精瓶。

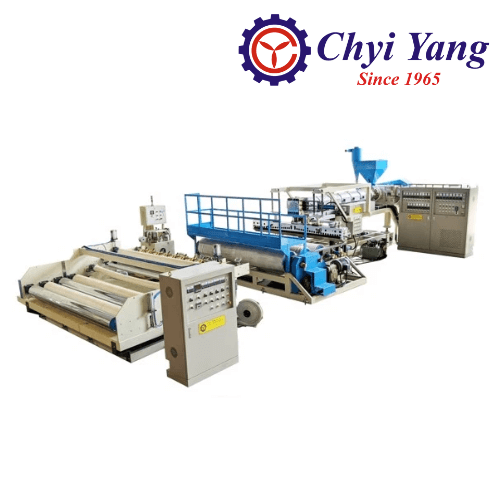

PE Stretch Casting Film Extrusion Machine

产品分类 : 薄膜和片材挤出生产线

T-Die Extruder machine can produce waterproof PE film for baby diaper, sanitary napkin, folders, table cloths, medical film, etc. Film thickness 0.03~1 mm Equipped with a fully automatic winder with cutting and changing rolls functions Hydraulic screen changer for short maintenance stop We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

医疗用防水抛弃式桌上切纸机 SHCG-42MP 型

产品分类 : 纸袋制袋机

The paper bag cutting and making machine features 1. Servo Motor Driven for precise length cutting. 2. Infeed Dance Roller Control with inverter Motor. 3. Air Cylinder Lifter Heavy Duty Unwinder for 300KG Paper Roll. 4. Collect Conveyor for friendly operation.

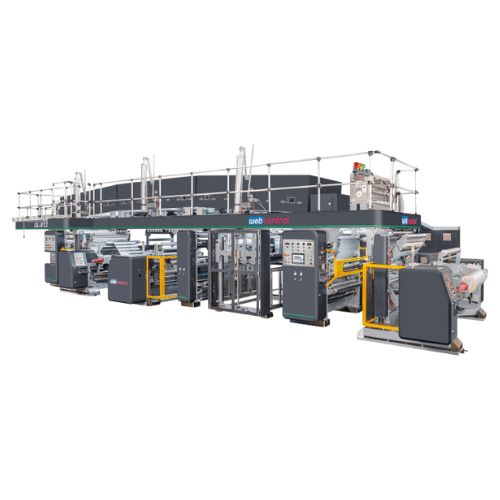

有轴式干式贴合机

产品分类 : 工业复合机

气压轴式收料座 - 平滑轮 平滑轮是由空气压缩机操作 指数操作可提供细微的校正接点,使接触的位置容易显示 平滑轮与压力轮分别在材料两端同步运转上升 - 烘箱 干式贴合机有三个8.1米的烘箱 第一烘箱位在右边利用V行喷嘴使热气均匀喷出 第二和三烘箱位于左边利用多孔版来高效能烘干 - 独立马达装置 由独立马达来驱动涂胶轮和带胶轮来避免因为打滑而造成涂胶不平均 - 快速更换欧式套筒 - 双层胶锅: 空气吸入装置是外层配备,用于抽吸溶剂的气味,避免气味飞溅 - 开放式刮刀 - 封闭式刮刀 没有胶水溅出当机器在高速操作时 最小溶剂气味 方便安装和清洁 最低液体粘度的变化 刮刀寿命长

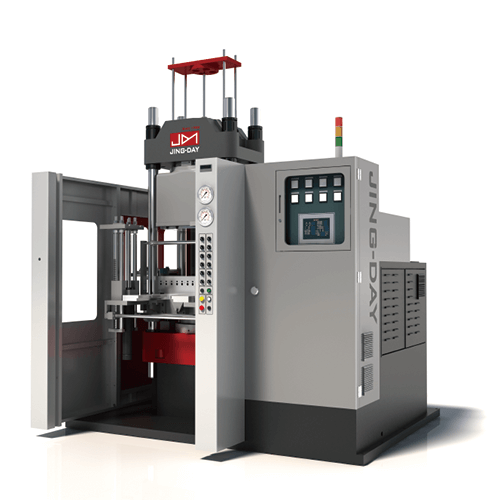

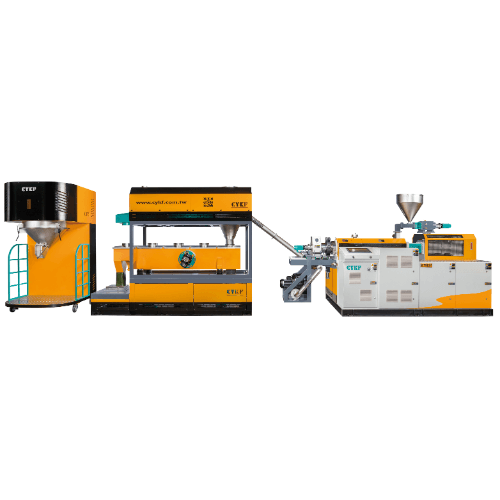

Overmolding Injection Molding

Overmolding Injection Molding Technology is a multi-material molding process that combines two or more materials in a single mold to enhance structural integrity, comfort, and functionality. This process allows flexible materials (such as TPE, TPU, or silicone) to be molded over a rigid substrate (such as ABS, PC, or PA), providing superior grip, durability, and impact resistance. This technology is widely used in automotive, electronics, medical devices, and consumer products, particularly for components requiring ergonomic design, shock absorption, anti-slip surfaces, and sealing properties. Compared to traditional assembly methods, overmolding technology offers cost savings, improved structural integrity, and an enhanced product appearance and feel.

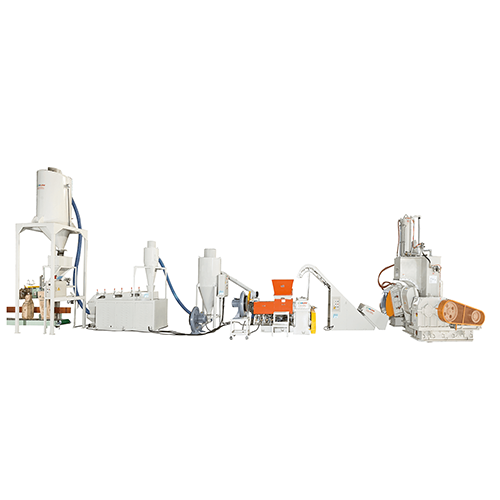

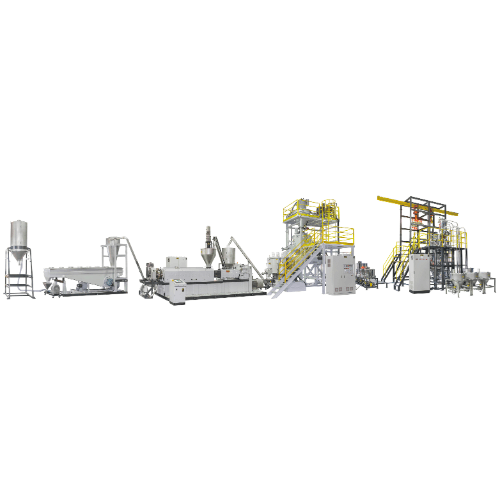

Medical Grade PVC Pelletizing Extrusion Line | CK-DT

产品分类 : 双螺杆挤出机

CYKF has good reputation in PVC extrusion. Our CK-DT Counter-rotating Twin Screw Extruder is especially designed for PVC production; the available screw diameter is between 55 to 130mm. Thanks to our technical team put long term effort on PVC extrusion technology which makes CYKF’s PVC extruder is competitive compared to other competitors. The high-efficient and durable PVC pelletizing machine can produce rigid PVC, soft PVC, medical grade PVC, UPVC, CPVC, and additives of foam or wood powders. It has outstanding performances that has earned highly praises from global customers.

PVC Automatic Metering / Weighing / Conveying Pelletizing Extrusion Line | CK-DT

产品分类 : 双螺杆挤出机

CYKF has good reputation in PVC extrusion. Our CK-DT series Counter-rotating Twin Screw Extruder is especially designed for PVC. The available screw diameter is between 55 to 130mm. Thanks to our technical team put long term effort on this field which makes CYKF’s PVC extruder is competitive compared to other competitors. Our durable and high-efficient PVC extrusion pelletizing line is able to produce rigid PVC, soft PVC, medical grade PVC, UPVC, CPVC, and additives of foam or wood powders. We are pound to say the PVC extrusion line made by CYKF is no doubt the best choice for customers. Possible materials : UPVC, CPVC, Medical grade PVC, Soft PVC, Rigid PVC, Foam and wood powder additives.

Ultrasonic Therapeutic Massager KUP-200

KUP-200 is working with 1 million times ultrasonic vibration per second which causes the tissues to compress and expand.The mechanical and thermal effects help to localized increase of blood flow and for the treatment of selected medical conditions such as temporary relief of minor pain, muscle spasms, and joint contractures.

Inspection Rewinding Machines INSPECT-SB

产品分类 : 分切机和复卷机

This double-side rewinding machine can do more serious inspection for the better quality, especially for packages of medical, cosmetics and some high-price food products. Integrated with automatic defect system, this machine can reach precise and continuous inspection to ensure zero defects.

Insert Injection Molding

Insert Injection Molding Technology is a manufacturing process that integrates pre-placed components, such as metal inserts, electronic parts, or other materials, into a plastic injection mold. During molding, molten plastic encapsulates the insert, creating a single, durable, and high-precision component. This technology enhances product strength, reduces assembly costs, and improves reliability, making it widely used in automotive, electronics, medical devices, and consumer products. By ensuring strong adhesion between plastic and inserted components, insert injection molding enables lightweight designs, enhanced durability, and improved performance in various applications. Key Advantages: Seamless integration of metal and plastic components Higher product strength and durability Cost-efficient by reducing assembly steps Customizable for complex geometries Enhanced precision and consistency Common Applications: Automotive Parts – Armrest trim panels, dashboard components, connectors Electronic Components – Connectors, circuit boards, protective casings Medical Devices – Surgical tools, sensor housings, implantable components Consumer Goods – Power tool grips, ergonomic handles, durable casings

医疗器材(TM 系列)

产品分类 : TPR(热塑性橡胶)

Ever Polymer的使命是满足市场上热塑性弹性体(TPE)原材料的所有应用需求。 TPE TPE医用TPR TPE材料TPE材料环保TPE材料制造商TPE材料性能TPE材料有毒TPE塑料回收TPE原材料TPE橡胶TPE材料TPE材料安全

85-150 ton injection molding machine product

产品分类 : 注塑产品

This 85-150 ton injection molding machine is designed for high-precision plastic product manufacturing, including automotive components, electronic parts, appliance housings, medical devices, and consumer goods. Equipped with a high-efficiency servo-driven system, it ensures stable injection pressure and precise control, delivering superior molding quality. With a high-rigidity clamping structure and an optimized hydraulic system, this machine offers durability and operational efficiency. It supports various plastic materials (PP, PE, ABS, PC, PA, etc.) and can be customized with multi-stage injection units and robotic interfaces for full automation, reducing labor costs and increasing productivity. Ideal for OEM manufacturers, plastic molding factories, and precision molding industries, this model meets modern production demands with efficiency and precision.

医疗消毒袋制袋机

产品分类 : 塑料制袋机

1. Main drive AC motor + inverter control. 2. The Sterilized Pouch length is accurately controlled by servo motor incorporated with mark sensor for greatly upgrading the production speed. 3. Twin Rolls unwind stand suits for two layers of different materials and multi-line production which upgrades efficiency greatly. 4. Two sets of dancer-roller unit provide the stable feeding tension both upper and lower web. 5. Equipped with microprocessor PID temperature controllers provide the most accurate and fastest heating performance. 6. Equipped with two sets of shear knives for bag partition. 7. Micro computer control system.

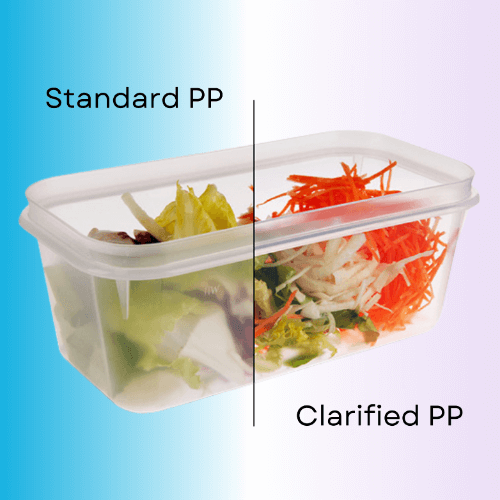

Millad® NX™ 8000

产品分类 : 添加剂

Millad NX 8000 helps PP producers and converters to stay ahead of packaging, appliances, medical, houseware and food storage trends by achieving unprecedented transparency in polypropylene. This innovative clarifier creates exciting new opportunities for your products, including significant energy savings and faster production in injection molding. Suitable for all conversion processes, Millad NX 8000 makes polypropylene a viable alternative to glass or amorphous polymers like PC, PET, PVC and PS. PP clarified with Millad NX 8000, known in the market as NX UltraClear PP, answers the growing demand for clear, attractive products and sustainable, cost-efficient production.