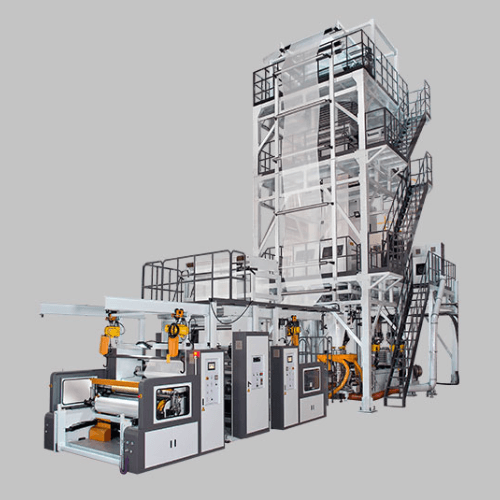

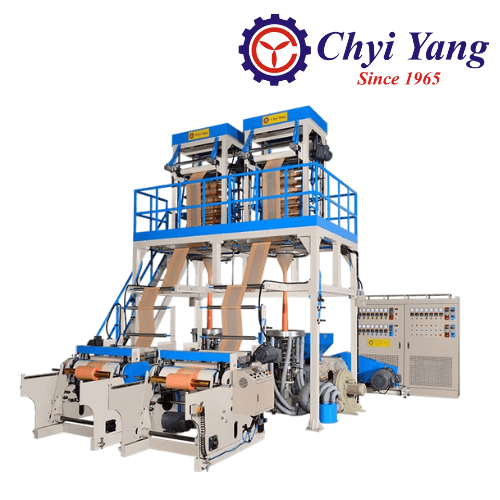

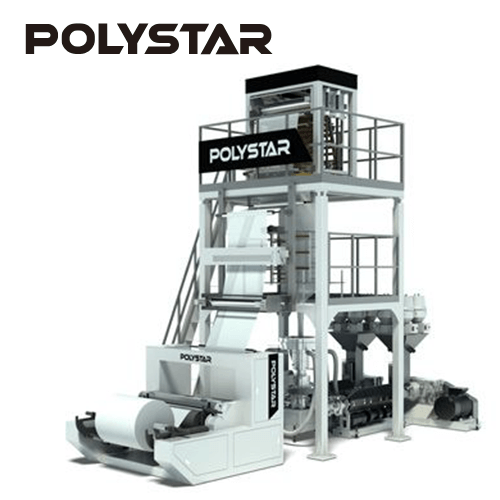

3-LAYER CO-EXTRUSION BLOWN FILM MACHINE

产品分类 : 共挤吹膜机

Application for greenhouse sheet, agricultural films, construction sheets, food packaging, sacks, shrink films, shrink hood films, and more. Max. film width of up to 4.2 m (8.4 m for single-layer-opened films) It supports a wide range of raw materials such as HDPE, LDPE, LLDPE, EVA, MPE, PP, and others. The machine is equipped with three sets of gearboxes and motors for independent control. Optionally, a 360º Oscillating Nip roller device can be added to ensure uniform film thickness and improve the performance of the rotary die device. The machine can be equipped with a "Waste Film Recycling Machine" which enables direct feeding of waste film into the screw, eliminating any waste plastic film and reducing costs. Please note that the models shown here are not exhaustive. If you require larger extruders, please feel free to contact us.

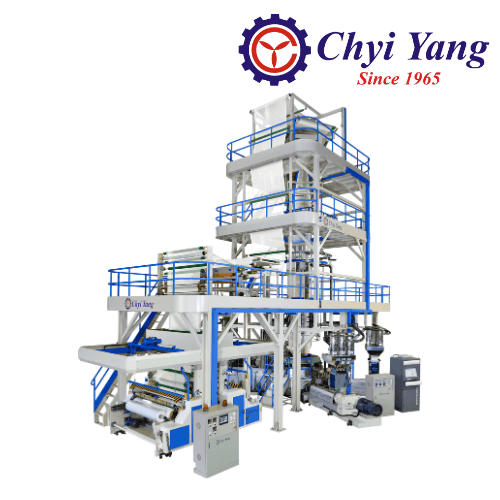

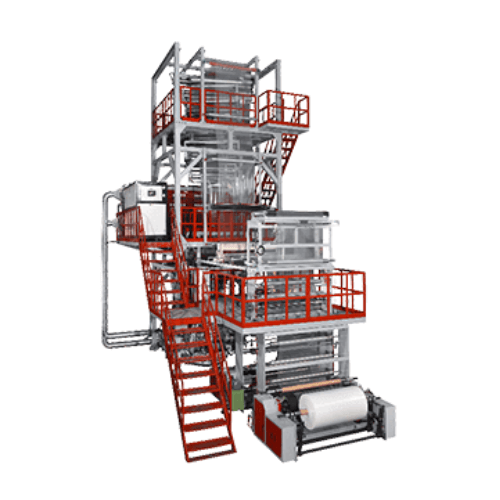

2-LAYER CO-EXTRUSION BLOWN FILM MACHINE

产品分类 : 共挤吹膜机

Available for agricultural film, coated film, stretch film, cling film, greenhouse film etc. Max film width up to 4.2 m (8.4 m in single-layer-opened film) Raw material HDPE, LDPE, LLDPE, EVA, MPE etc. Two sets of gearbox, motor & extruder for independent control For producing PE stretch/cling film, PIB liquid adhesion system can inject liquid adhesion into screw directly to save resin cost & adjust the stickiness ratio you need Purchasing PIB system can produce out-layer film non-sticky to prevent dust, in-layer film sticky to pack subjects Optional “Waste film recycling machine” lets this machine doesn’t have any waste plastic film, it can feed waste film directly into screw to save your cost We didn't show all our models, please don’t hesitate to contact us for bigger extruders.

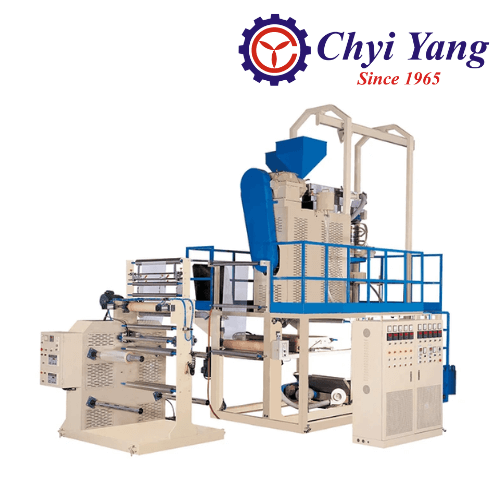

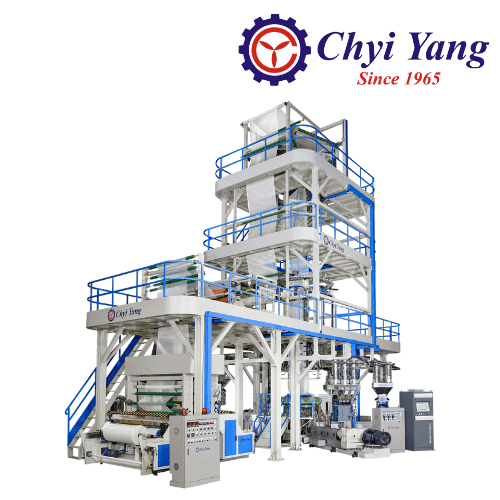

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine

产品分类 : 共挤吹膜机

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine, CHYI YANG is Multilayer Co-Extrusion Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably linked with the life and development of plastic machinery in Taiwan.

7-LAYER CO-EXTRUSION BLOWN FILM MACHINE

产品分类 : 共挤吹膜机

CHYIYANG specializes in manufacturing 7-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

ABA 3-Layer Co-Extrusion

产品分类 : 共挤吹膜机

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.

ABA 3-Layer Co-Extrusion

产品分类 : 共挤吹膜机

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.

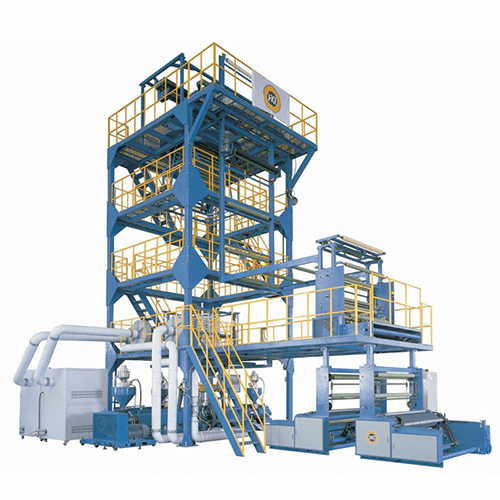

5-LAYER CO-EXTRUSION BLOWN FILM MACHINE

产品分类 : 共挤吹膜机

CHYIYANG specializes in manufacturing 5-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

ABC三层共挤吹膜机

产品分类 : 共挤吹膜机

依托多年的擠出製造經驗,我們了解塑料吹膜擠出製程的各項原理,我們具有吹膜生產線的製造能力。此外,富隆的塑膠吹膜機,是依據原料特性及最終應用而量身訂做。在產品設計前,恆隆重視與客戶的溝通與討論,以建立與客戶的依賴。依據原料的用途,我們提供從 3 層到 5 層的共擠塑膠吹膜機。此外,最終產品在大幅降低成本的同時,也具備了所有所需的特性。

Blown Film Machine BFS-55-65-55-1400

产品分类 : 吹膜挤出机

FKI提供最先进和适应性最强的吹塑薄膜生产线之一,如购物袋,背心袋,垃圾袋,农用薄膜,建筑膜,包装薄膜和复合薄膜等。可以使用的可用材料是如LDPE,LLDPE,MLLDPE和HDPE。薄膜生产范围从200毫米到7米不等,生产产量从40公斤/小时到800公斤/小时。基于30年的经验,FKI能够提供具有可靠性和多功能性的吹膜生产线,以满足单层,双色,双层,三层到四色设计的不同要求。

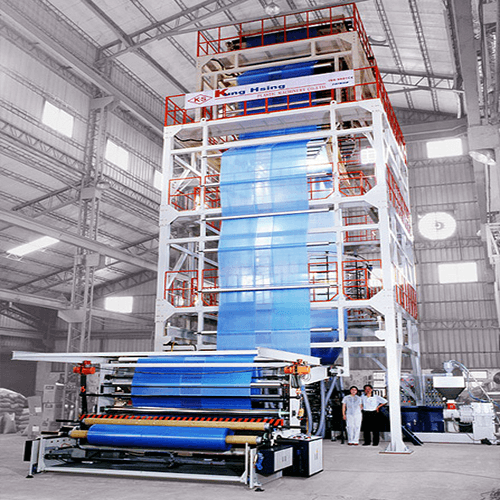

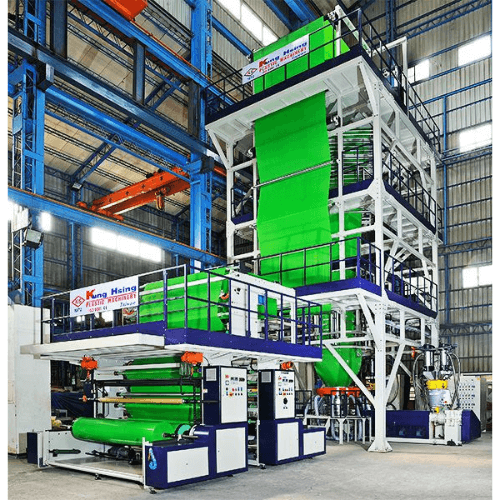

LDPE五层复合吹袋机KS-ML-5-50

产品分类 : 共挤吹膜机

光兴已达到ISO 9002的要求, 机台符合CE的标准, 使光兴成为一个世界级的公司, 不仅如此, 每台机台在运送至用户端前都必须通过光兴严格仔细的品管系统和测试。

A/B/A BFT Series Co-Extrusion Blown Film Line- Oscillating Tower Type

产品分类 : 共挤吹膜机

管状平放宽度:40mm至7米。 -单层,两层,三层和五层-单色,双色,最多4色。

HDPE/LDPE/LLDPE三层共挤吹袋机

产品分类 : 共挤吹膜机

● ABA 3 Layer Co-extrusion ● Film Width from 500~1500mm ● Extruder Dia: 40mm,45mm, 55mm, 65mm ● Material: HDPE,LDPE, LLDPE,CaCO3, Additives ● Output: 45~150 kgs/hr

三层共挤吹膜机

产品分类 : 共挤吹膜机

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

ABA三层共挤吹膜机

产品分类 : 共挤吹膜机

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

五层共挤吹膜机

产品分类 : 共挤吹膜机

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.