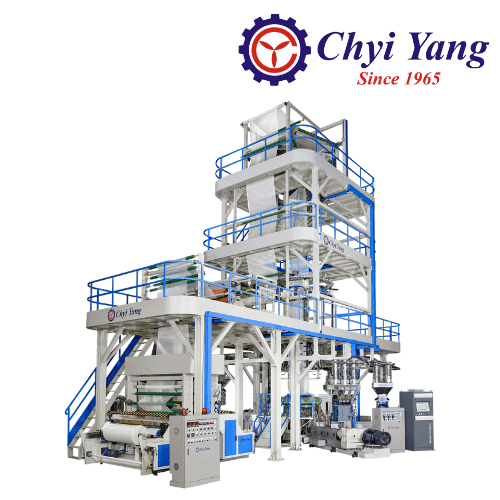

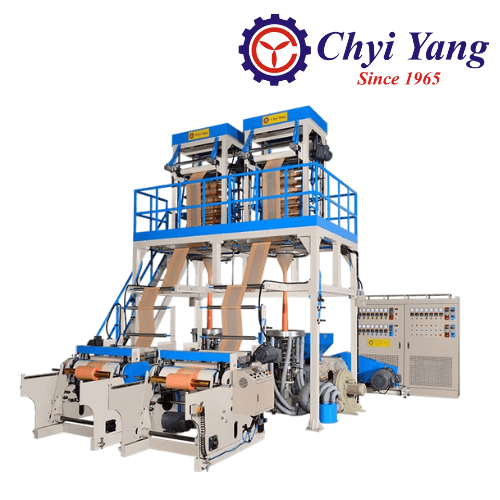

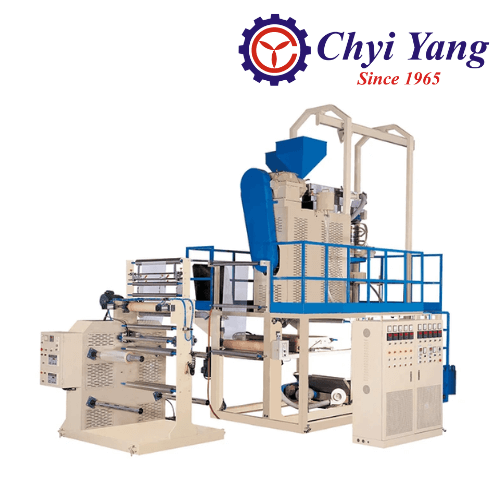

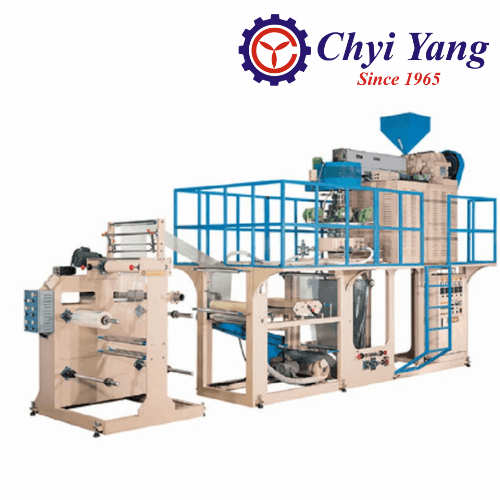

- Application for greenhouse sheet, agricultural films, construction sheets, food packaging, sacks, shrink films, shrink hood films, and more.

- Max. film width of up to 4.2 m (8.4 m for single-layer-opened films)

- It supports a wide range of raw materials such as HDPE, LDPE, LLDPE, EVA, MPE, PP, and others.

- The machine is equipped with three sets of gearboxes and motors for independent control.

- Optionally, a 360º Oscillating Nip roller device can be added to ensure uniform film thickness and improve the performance of the rotary die device.

- The machine can be equipped with a "Waste Film Recycling Machine" which enables direct feeding of waste film into the screw, eliminating any waste plastic film and reducing costs.

- Please note that the models shown here are not exhaustive. If you require larger extruders, please feel free to contact us.

| MODEL NO. | THDP-35 | THDP-45 | THDP-55 | THDP-65 | THDP-75 |

| Screw Diameter (mm) | 35 x 3 sets | 45 x 3 sets | 55 x 3 sets | 65 x 3 sets | 75 x 3 sets |

| Output (Kg/hr) * | 35-90 | 50-100 | 60-120 | 70-150 | 80-200 |

| Roller Width (mm) | 750 | 1000 | 1200 | 1600 | 2000 |

| Film Thickness (mm) | 0.025~0.2 | 0.025~0.2 | 0.025~0.2 | 0.025~0.2 | 0.045~0.2 |

| Power Required (Kw) | 75 | 90 | 130 | 160 | 180 |

| Drive Motor (HP) | 15 x 3 sets | 20 x 3 sets | 30 x 3 sets | 40 x 3 sets | 50 x 3 sets |

| LDPE Die Diameter (mm) | 100 or 150 | 120 or 200 | 150 or 300 | 450 | 800 |

| Machine Dimension (m) | 8.4 x 3.5 x 6.5 | 8.8 x 4 x 7 | 9.2 x 4.5 x 7.5 | 9.6 x 5 x 8 | 10 x 6 x 8.5 |

*Output depending on film width, thickness, die size, raw material.

*For more details specification, special requirements & quotation, please kindly contact us