色料色母自动计量器 (MF)

产品分类 : 进料器

传统人工配色需经多次对色、拆装、搅拌,搬运等繁杂手续,且对工厂环境及工作人员的健康危害极大,而本公司色料色母自动计量器与各类成型机同步自动配色混料,可节省工时、原料、仓储空间、采购成本及防止工厂环境之污染。 透过专利设计的底座,色母料与塑料粒不会累积在入口处与螺杆间,可将色料、色母、添加剂和能自由滑落的粉末料、粉碎 料及主要原料等精确地自动计量,避免人工配色混料所产生的误差及原料的浪费,使成型品的颜色保持一致性。 成型品颜色的转换只需清理本机之进料螺旋杆,短时间内 即可改变颜色,省时又方便。 内部做过特殊处理,计量精准且无死角,容易清理,无卡料之烦恼。 转速(R.P.M)不受外界电源不稳定之干扰,能精确固定于所设定的转速,因此添加色料、色母或其他添加剂时皆能保持均匀稳定。 只需将主原料的使用量及色料、色母或其他添加剂之添加率输入,计算机即自动运算转速,操作简单,且有多组记亿储存功能,使成型工作之 转换更加得心应手。 针对间歇进料之射出成型机,亦配备有自动定时器,可免除成型机进料时间不定,造成色母添加量不稳定的困扰。

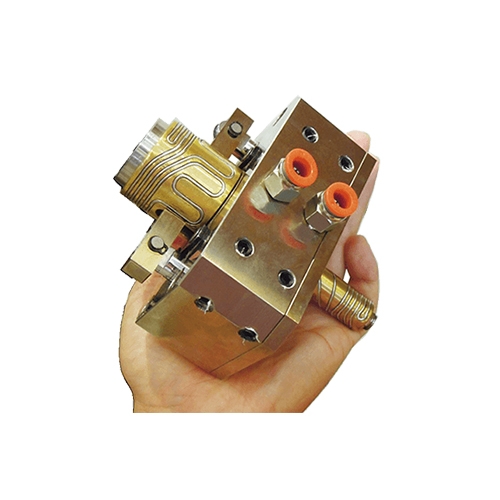

密封式高速混合机

产品分类 : 橡胶搅拌机

This Intensive Mixer is designed for mixing compounds and specific plastic. The structure of the machine consists of the main air cylinder, floating weight, feeding door, mixing chamber, rotors and discharge device. When performing mixing compound operations, the material and ingredients are fed together into the mixing chamber. The material in the mixing chamber is repeatedly sheared and squeezed by the rotors. This provides a series of chemical rotations between the material and the ingredients, which enables the material pieces to stick together into a paste mass shape. Mixing compound operations are performed according to the set temperature and conditions. This specially designed mixing machine provides efficient mixing and refining for a wide range of raw materials, such as raw rubber, resins, asphalt, cellulose, PVC ane EVA…etc.

油压式自动送料冲型裁断机 (四柱式) (模切机)

产品分类 : 切割机

应用范围:适用于橡胶胶片(鞋底、中底)、EVA, 海棉,皮革、塑胶、帆布、泡棉、尼龙、地毯、脚垫、纸皮、软木、软瓦片、及各种合成材料一层或数层的成型裁断镒群

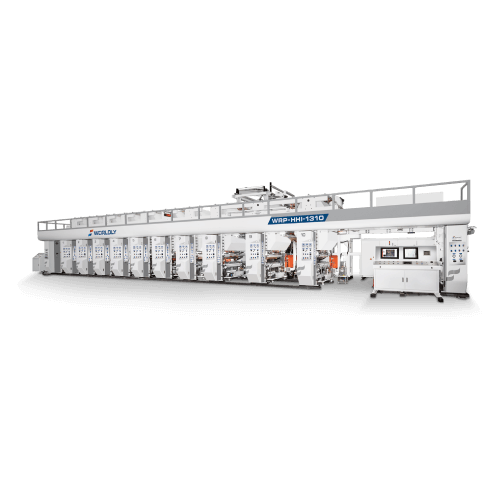

铝箔专用型印刷机- 独立马达系统(WAP系列)

产品分类 : 凹版印刷机

为了符合业者多元印刷产品,印刷结构规划六色印刷座,末端再搭配一座涂布座,可于铝箔印刷后直接上光,提高铝箔的印刷效果,此涂布机亦可做背胶使用,足以应付各种不同印刷需求。每一色印刷座之间,都搭配适用于铝箔材质的特殊翻转结构,再结合于正反两侧设置刮刀座,使业者能够任意在任何一色进行反面印刷,轻松达成各种的印刷要求。此外,每座印刷座采用「日本住友重机」独立马达系统,可于印刷作业的同时,更换下一个工作单的印刷版筒,不但节省作业时间,更提升套色的反应时间及效应。此机型还另外附加一座干燥系统位于机台上层,具有四区隧道式的干燥风箱,其干燥效率更加迅速。放料及收料座采双轴式自动接料,不需停机即可完成续料作业,操控简易。全机以高性能的PLC数位控制器搭配触控式人机介面做连动控制,精准且确实达到高效率的操控效能,并具有自动套色功能,让印刷密度及品质更臻至完美。在品管方面,玮礼设置VIDEO检视系统,即使在高速印刷作业下也能即时做到品管监控,有效协助印刷作业与品质提升。

胶版印刷机PKF-8 系列

产品分类 : 柔版印刷机

● Machine framed with 50MM cast metal plate, provide a very steady, vibration free foundation for the printing work. ● All gears are helical design. ● AC main motor from Siemens and controlled by Japan made inverter to provide a steady speed performance. ● Inking rubber rollers are driven by European made hydraulic motor independently, speed can be adjusted for controlling ink transfer volume. ● Simple but accuracy and steady vertical and horizontal image adjustment device. ● Long arch type drying tunnel with high capacity blower, to allow ink quick drying during high speed operation. ● Bearing house design for holding rubber roller, plate cylinder and anilox roller. ● Machine can be equipped with Japan auto tension controlling system, close chamber doctor blade, EPC at unwind, rewind as optional choice. Flexo Stack printing Machine Flexographic printing machine CI Flexoprinting Machine Flexographic Printing Machine FLEXOGRAPHIC PRINTING MACHINE FLEXO PRINTING MACHINE FLEXO STACK PRESS FLEXO PRINTING PRESS CI PRINTING PRESS CI PRINTING MACHINE PAPER PRINTING MACHINE PAPER PREPRINT PRINTING MACHINE OFF LINE PRINTING MACHINE

柔版印刷机

产品分类 : 柔版印刷机

● The BOTHEVEN Flexographic Printing Press #MP Serial is design for fabric sheet printing, such as after cutting and bottom sewing of laminated or un-laminated bag, paper bag ....etc. ● Easy operation, easy change printing plate. ● Special design a Action Roller dispense device, the printing cylinder won't dirty conveyor when empty load.

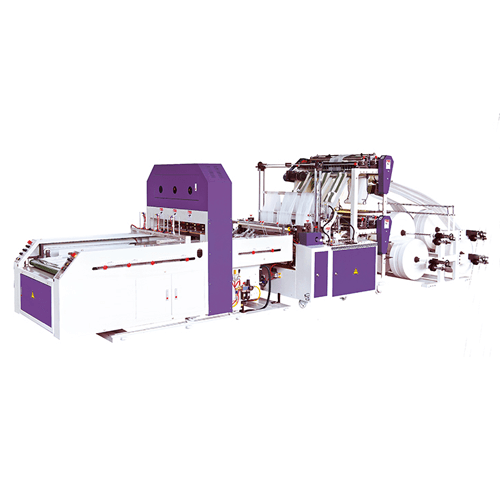

底封制袋机+折袋装置

产品分类 : 塑料制袋机

自动折袋系统 - 第1折和第2折(逐件)为伺服控制,第3折由气缸控制,每1-15件堆叠。第4和第5折可选配。 冷切系统 - 用于薄膜材料。机器采用上热刀和矽利光轮进行封口。袋子出料前切刀。

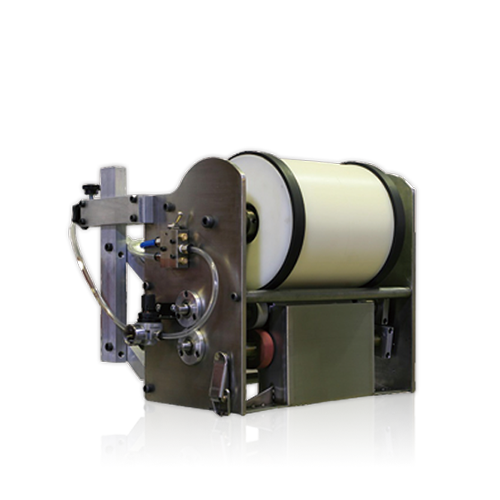

打样机

产品分类 : 分切机和复卷机

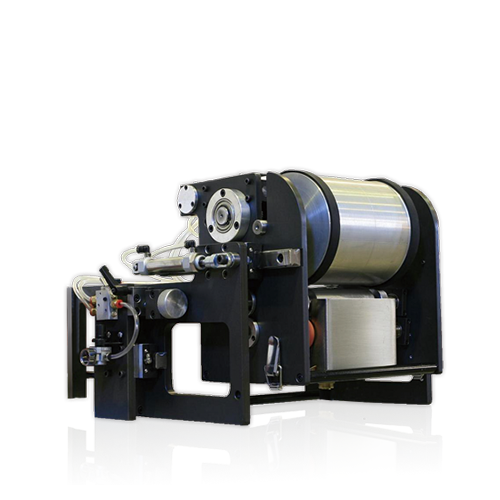

FCM-1300适用对象 制版工厂,印刷工厂。 FCM-1300超强功能 检查版胴,包含字样及色泽深浅度的正确性。 试印不同色泽的样品,提供客户多样选择性。 FCM-1300特出优点 一人操作。 十分钟完成打样。 减低油墨及材料的浪费。 增加生产印刷的时间。 可使用印刷用材料及油墨。 FCM-1300 卓越性能 1. 印刷轮机械式定位 以近接开关做感应,配合机械式定位,确保每次印刷前精确定位。 2. 高解析镜头,放大屏幕辅助定位 高分辨率镜头,加上16倍放大屏幕显示,可清楚抓住版胴上的记号(箭头),辅助寻找每支版胴上的定位箭头,减低目视定位的误差。 3. 可调式刮刀装置 刮刀片由两片组合式,增加硬度。可视版胴花样调整刮刀角度及压力设定。 4. 无轴式顶版座 取代传统轴心式置版,可单一人工操作,可依版胴宽窄作左右调整,上版容易且安全。 5. 可调式托版架 托版架以气压方式调整版胴上下位置,版胴拆卸方便,防止人工操作的危险。 6. 超大型印刷轮 (1)电镀铬研磨的印刷轮,平滑度好且防锈耐用。 (2)弹性佳的印刷用胶皮布,可与印刷轮彼此紧密密合。备有螺丝更换装置,胶皮布于污损或损坏时更换容易。 (3)印刷轮轴长达2500mm,视版胴的圆周长大小,一次可印出2份以上的样品,便于检视. 7. 向量式印刷驱动马达 刷轮传动以7 1/2HP 的向量式马达驱动。 8. 可调式打样速度 打样速度范围为20-90m/min.,可配合客户使用之材料厚薄及油墨性质调整。 9. 线性滑轨 应用于顶版座及胴座的直线移动装置皆采用线性滑轨,定位精度高,使平台作线性移动时,不会有打滑现象发生。

标志凸版/胶版印刷机LW-LF100-E

产品分类 : 柔版印刷机

印刷版轮尺寸可更换尺寸从500mm到800mm连续印刷长度,标准配备500mm印刷长的版轮,可携式胶版/凸版印刷机,适合于印刷商标,标志,文字及各式各样的单色印刷需求。被动式机器安装于吹袋机,制袋机及任何传动式设备,透过膜料拖动驱动印刷头做印刷动作,不需要供电非常的经济和容易操作。

独立凸版/胶版印刷机LL-6000

产品分类 : 柔版印刷机

卷对卷式的独立式凸版/胶版印刷机,印刷的品质非常的好可以做印刷套色4+0,3+1,2+2,机器标准为手动式张力控制,铸铁机身粉体烤漆,非常的坚固及耐。上部配置2组燥箱,在膜料经过印刷座后引导至干燥箱做干燥处理,确保膜料可以配合速度做干燥。适用材质: 卷到卷印刷的玻璃纤维布,玻璃纸,铝箔,滚筒纸,包装纸,管状膜,和PP/ HDPE/ LDPE / LLDPE聚酯袋,PP / HDPE / LDPE / LLDPE聚酯袋。

医疗用防水抛弃式桌上切纸机 SHCG-42MP 型

产品分类 : 纸袋制袋机

The paper bag cutting and making machine features 1. Servo Motor Driven for precise length cutting. 2. Infeed Dance Roller Control with inverter Motor. 3. Air Cylinder Lifter Heavy Duty Unwinder for 300KG Paper Roll. 4. Collect Conveyor for friendly operation.

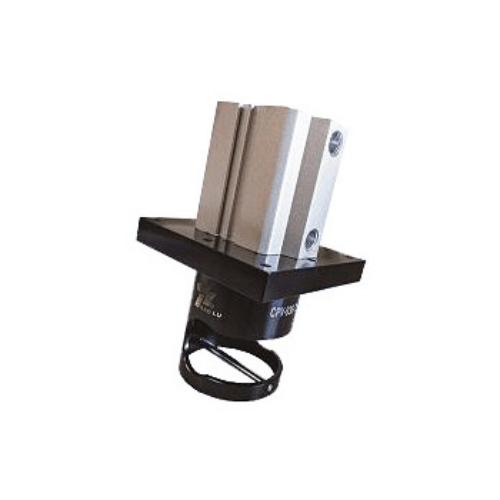

混合比例阀 (PV)

产品分类 : 分离器

Proportional Valve (PV) The unique air valve structure design stops dust from entering the cylinder of the unit and thus reduces waste. Can mix or feed one kind of resin only if required. The controller is fitted with digital readout (PV-A-D Series) and setting for the mixing cycles which gives a high rate of accuracy. It is easy to set and be set in the range of 0-9.9 seconds. Transparent cleaning cover design for quick cleaning and easy changing materials. Individual controller for convenient operation.

标志凸版/胶版印刷机LW-LF100-F

产品分类 : 柔版印刷机

可携式凸版/胶版印刷机,适合于印刷商标,标志,文字及各式各样的单色印刷需求。被动式机器安装于吹袋机,制袋机及任何传动式设备,透过膜料拖动驱动印刷头做印刷动作,不需要供电非常的经济和容易操作。适用材质: 卷到卷印刷的玻璃纤维布,玻璃纸,铝箔,滚筒纸,包装纸,管状膜,和PP/ HDPE/ LDPE / LLDPE聚酯袋,PP / HDPE / LDPE / LLDPE聚酯袋。

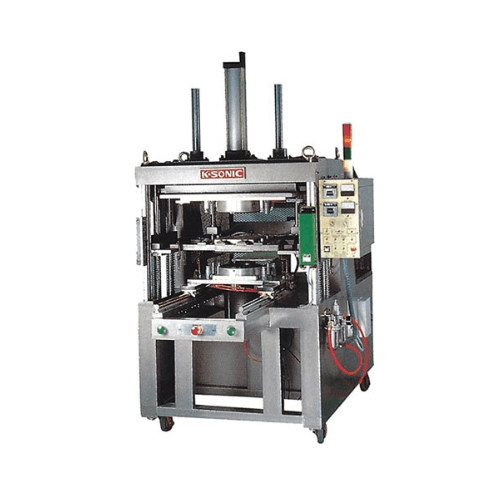

Hot Plate Plastic Welding Machine KH-31

The machine is constructed of main body, hot mold set and upper & lower fixtures. Only upper fixtures declined by cylinder. The welding part's surfaces melted in proper welding time when pressed against the hot plate The hotplate retracts and forced welding parts together in proper holding time Enable to weld two mold cavities in one stroke

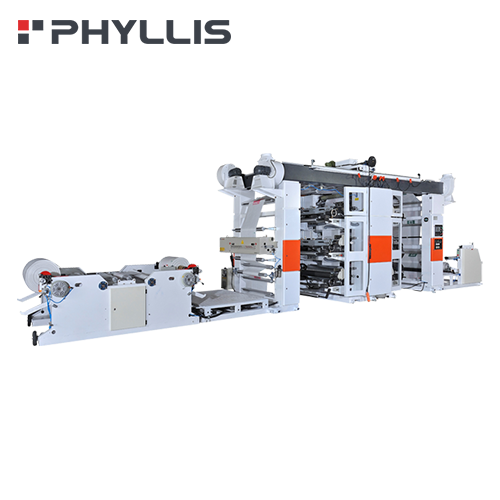

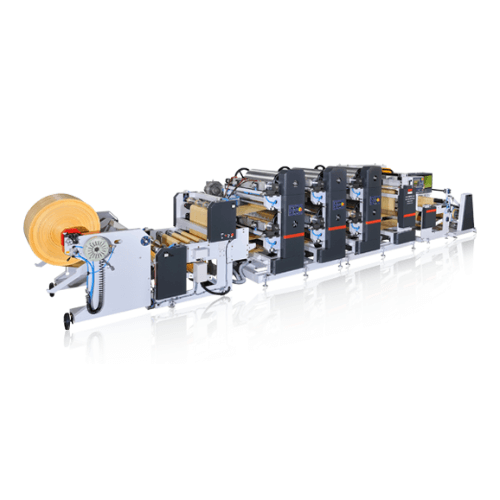

Reel to Reel Flexographic Printing Line FSRP-6C (No Cylinder Changing)

Equipped Servo Motors for Precise Printing Graphic and Printing Length Control On-line Servo Control Printing Position Registration System (with Touch Screen Operation) (Each printing station equipped with servo motor to adjust printing position during machine running) Equipped with On-line Camera Inspection (Italy made) Two Units, Monitoring Printing Quality during Machine Running. Equipped with Doctor Blade System and Ceramic Anilox Roller as Standard Equipment

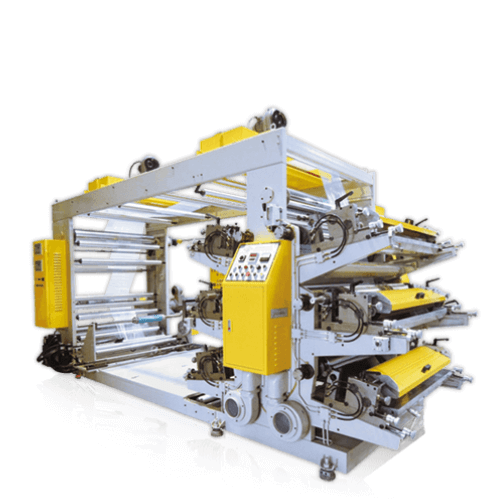

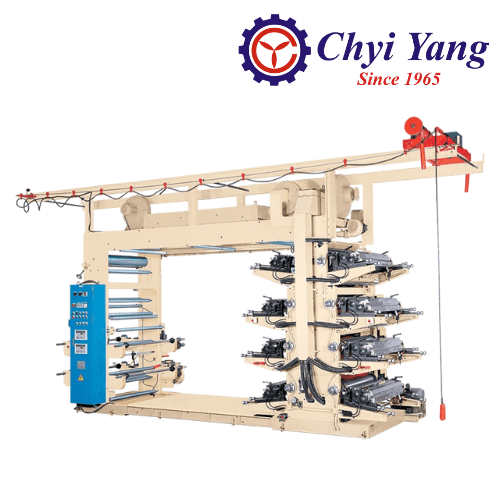

8 COLORS FLEXO PRINTING MACHINE (HIGH SPEED TYPE)

产品分类 : 柔版印刷机

Our machines are suitable to print PP, PE, BOPP, OPP, PE shrinkable film, packing paper, glass paper, non-woven bags. Using hydraulic system to lift up & down the printing cylinders for easy operation. Equipped with meter counter, the machine will stop automatically when reaching the meter. Using high-capacity hot air dryer to make the production faster. The dryer and fan will shut down automatic when machine stops. When machine stops, the ink rolls keep running to avoid drying of ink. The rubber roller is ozone-resistance & solvent-resistance. The ink tray is with cover & faucet. Ink pump, air shaft, ceramic roller & doctor blade etc. are options.

ELS独立马达高速型凹版轮转印刷机

产品分类 : 凹版印刷机

Ink resistance material of furnishing roller optimized ink circulation, avoid cylinder cell ink stock and improve printing quality. The roller driven by motorized can manual or automatic mode synchronized with printing speed. - Quick change over doctor blade holder design - Ink group trolley system for quick job change over - Centralized control system allow man power saving - Latest E.L.S technology

混合比例阀 (PV)

产品分类 : 分离器

‧适用于一般新的塑料与粉碎料相互混合。 ‧以两个定时器之比例差作交换吸引,将旧料酌量混入新料中,不但不会影响成品的质量,且可减少资源浪费,任何厂牌及机型之填料机皆可配合使用。 ‧设有混料选择开关,可依所需设定混合交换吸料或单独吸料,使工作之替换更加顺畅。 ‧数字设定的双定时器,可依所需的混合比例直接设定,而计时范围可介于0~9.9 秒间,能精确的混合两种塑料。 ‧节省空间、安装容易、易于清理,为您节省更多原料成本。 ‧独特的气缸结构设计,能减少原料被污染及延长之使用年限。 ‧不锈钢设计与透明窗口,使填料与清料的工作更得心应手。 ‧采主机与电路控制器分离设计,操作简单方便,且可因应各种工作环境之需求。

Hot Plate Plastic Welding Machine KH-33 (upper and lower cylinder type)

1.The machine is constructed of main body, hot mold set and upper & lower fixtures. Upper and lower fixtures moved by cylinder. 2.The welding part's surfaces melted in proper welding time when pressed against the hot plate. 3.The hotplate retracts and forced welding parts together in proper holding time. 4.Enable to weld two mold cavities in one stroke.

BJA3P+S-双层6线伺服控制全自动平袋背心袋封切机

产品分类 : 封口机

● 全机为双层6线制袋机。 ● 本机使用伺服送料,封切稳定性高,速度快改变尺寸容易,尺寸误差小。 ● 机器侦测到有异常时会立即停机。 ● 本机有自动冲床装置。 ● 热针之位置可自由移动。 ● 本机械可制作平袋及背心袋。 ● 采用增压式气缸冲床。动作快速、确实。没有噪音及漏油问题。 ● 附冲孔校正板,使背心袋手提位置达均一性,提高产品品质增加竞争力。

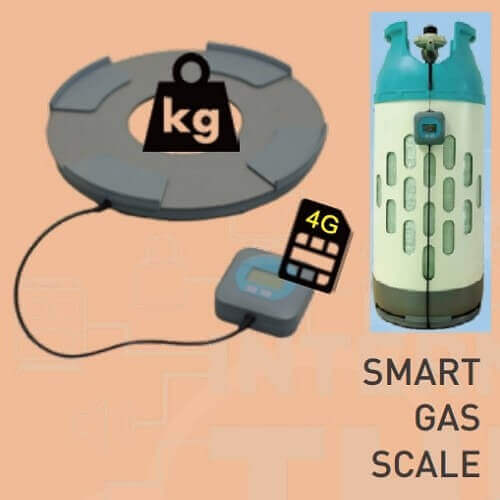

Smart Gas Scale for LPG

产品分类 : 指示器和传感器

立式关模立式射出机-YH系列

产品分类 : 立式注塑机

-四柱/垂直夹紧,垂直注射。 拉杆之间的矩形形状,易于插入。 -双注射气缸平衡,实现平稳,强劲的注射。 -结构简单,占用很少。 -双作用夹紧缸,用于快速夹紧,低速高压夹紧。 -单次滑动将下模推出,便于装卸。 -双重滑动使用两个下部模具,在操作员装载另一个模具的同时对零件进行机加工,以提高生产率。

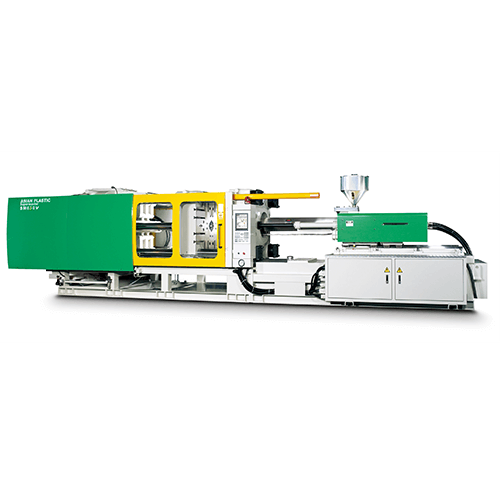

大型曲肘式伺服节能射出成型机

产品分类 : 卧式注塑机

• 超大的柱内距与容模量,固定板和活动板采有限元素法(Finite Element Analysis) 分析设计,以确保机械的强度及刚性。 • 采用双射移油缸可达到正确的模具对心效果,并可确保于高速高压射出时射嘴不会漏料。 • 线性滑轨射胶系统,减低机械耗损及背压产生,使产品射出更为精确。 • 采用BOSCH快速比例压力速度阀,此阀本身带有位置反馈,以及加装压力传感器,使得控制器所下达指令能够迅速反应回馈,达到敏捷精准的控制需求。

精密四柱式平面油压裁断机-CSS-202B

产品分类 : 发泡机械

●机械机体,使用特殊钢质制成,而且经过严格处理耐冲压,永久保持精密度。 ●上下行程采用钢柱为轨道,精密度高,永不摇晃。 ●两柱油缸,出力平稳,扭力大。 ●冲压时,有两段慢速功能,无震动,可减少裁垫损耗,产品无须边。 ●特有自动润滑系统,增长机械寿命。 ●工作物裁断调整器,简便,准确,10秒内可调整到适当深度。

高速曲肘式伺服节能射出成型机 (TSV 系列)

产品分类 : 液压夹模注塑机

特快锁模系统,采用油压差动回路,提高速度达60﹪以上,缩短周期,节省能源。 特殊无给油自润模板滑片,耐磨耐压,耐用性久。 自润铜司曲肘机构,确保机器之精度,可防止曲肘磨损。 采用BOSCH快速比例压力速度阀,此阀带有位置反馈,能够迅速反应回馈,达到敏捷精准的控制需求。 适用成型精密度高、薄壳成品之塑胶制品。 (成品厚度1 ㎜ L/t大于200) 蓄压器为选配装置。

Vertical Two Tie-Bar Injection Molding Machine

产品分类 : 液压夹模注塑机

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production, then reduce the cost of production. High precision mold platen (Parallelism/flatness:0.01/100mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact, space-saving design, reduce the heavy burden of the floor of factory.

Vertical Single Shuttle Table Injection Machine

产品分类 : 立式注塑机

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.