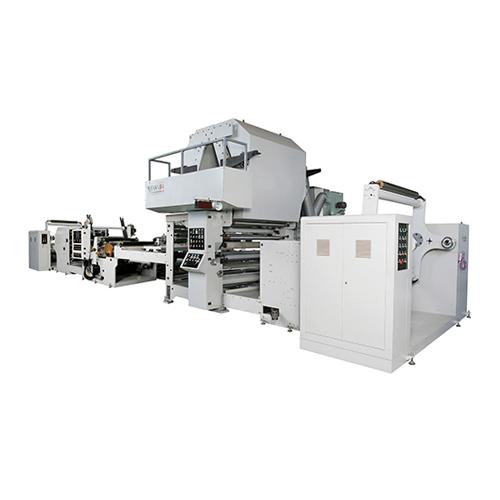

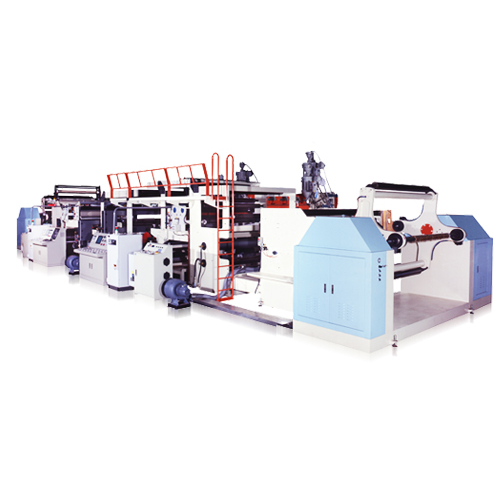

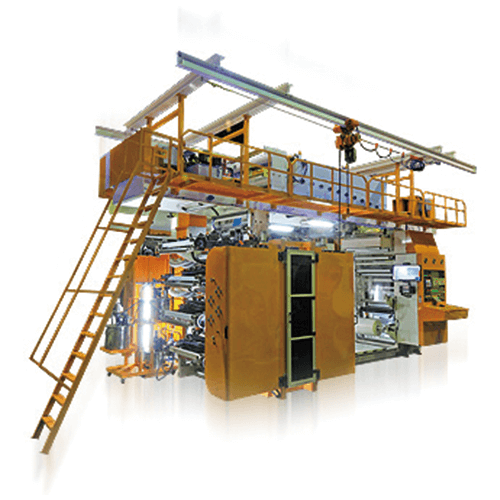

双面双层共挤压复合淋膜机

产品分类 : 淋膜机

主机压出量:350 Kgs x 2 Sets = 700 Kgs/Hour 副机压出量:150 Kgs x 2 Sets = 300 Kgs/Hour 线速:40-220 Meters/Minute 淋膜宽度:600MM~1600MM

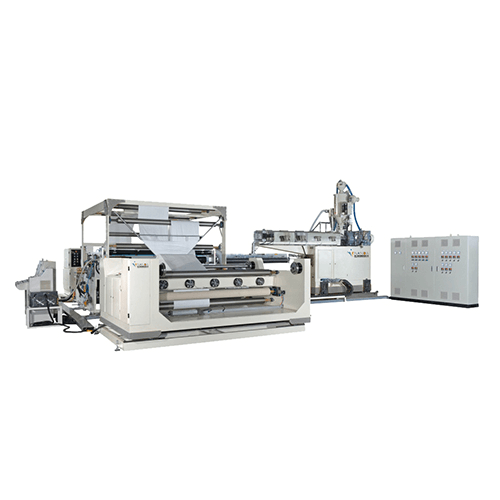

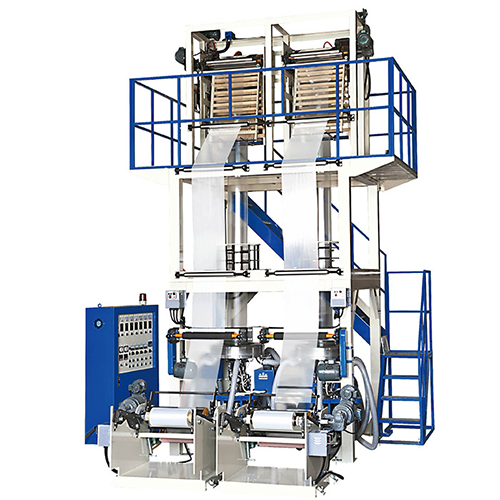

高速单层膜双膜头吹袋机

产品分类 : 吹膜挤出机

This two-head blown film machine line can produce 2 film rolls of the same width at the same time, and the production capacity is thus comparatively higher than models with only one die head. Thanks to the twin-head design, it not only occupies less space but also consumes less energy, which offers an economical solution for producing plastic bags of smaller width.

尼龙 6 工程塑料 - NA7200GK35

产品分类 : PA(聚酰胺)/尼龙

35%玻璃纤维增强 (黑色-高刚性、高耐冲击) 应用说明:手工具、电动工具、园艺工具用,汽车、机车、脚踏车零组件用,运动器材零组件用,电子、电器外壳及零组件用,O.A.办公室零组件用,水资材用,医疗复健器材。

Two Roll Mixing Mill (Open Mill)

产品分类 : 橡胶搅拌机

The Two Roll Mixing Mill For Rubber、Plastic、PVC、EVA To Heating、Mixing And Chemicals Or Sulfur Material Uniformity It Can Be As Instead Of The Calender To Produce Un-Exact Rough Sheet Process.

射出吹气成型机PK-IBT 系列

产品分类 : 注塑中空成型机

捆扎带挤出生产线(JC-BFY系列)

产品分类 : 吹膜挤出机

The JC-BFY series tying tape extrusion line by blown film extrusion process is speically designed to produce tying tape, polytwine, twisted twine for light packaging applcation, as well other general packaging and industrial application.

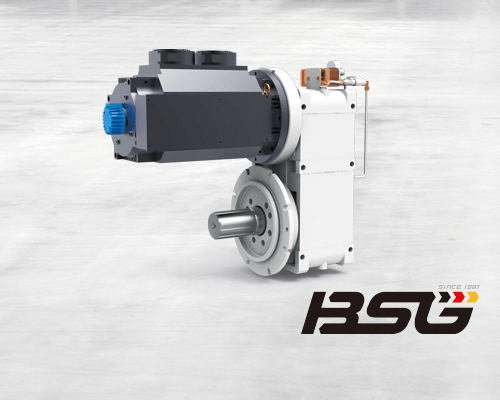

二板式伺服节能射出成型机

产品分类 : 压板注塑机

The actuator of the clamping force is installed on the fixed platen of the conventional two platens injection molding machine. The design of the MBE model has four sets of traveling cylinders inside of the movable platen to close the mold and to build up the clamping force at the center of the platen.

C型穿梭台低压成型机

产品分类 : 低压注塑机

Low pressure molding is a new injection molding process in recent years. Low pressure molding production is a process uses hot liquidify Polyamide material.

高填充量改质剂生产线

产品分类 : 复合线

高填料改性复合生产线(CaCo3,TiO2或滑石粉)我们的高填料改性复合生产线使用我们的挤出机械将不同类型的复合材料加工成粒料。我们简单的操作线,包括一个分散捏合机和挤出机,以满足您所有的具体化合物制作需求。 (高密度聚乙烯,再生高密度聚乙烯,二氧化钛,滑石,PP + CaCo3等)我们也可以为您提供自动化生产线,并根据您的需要调整和定制设备。

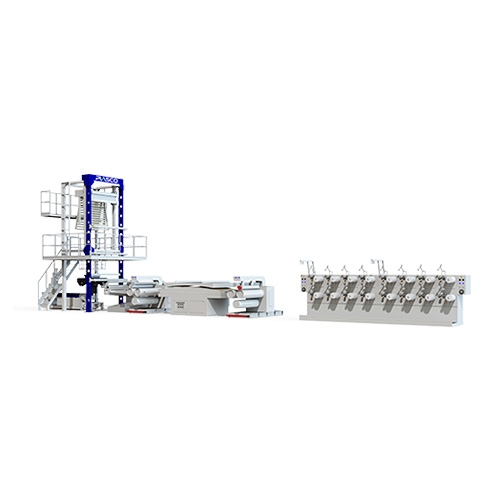

HP-FG800-8SP-200

产品分类 : 柔版印刷机

尼龙 66 工程塑料 - NB1200G15

产品分类 : PA(聚酰胺)/尼龙

15%玻璃纤维增强 (本色-高流动性) 应用说明:手工具、电动工具、园艺工具用,汽车、机车、脚踏车零组件用,运动器材零组件用,电子、电器外壳及零组件用,O.A.办公室零组件用,水资材用,医疗复健器材。

PS、PC材质专用热转印膜

产品分类 : 薄膜

各类塑胶制品、布丁桶、容器、金属外壳、家用品、文具用品、礼品…等多项商品。各种PC和PS制成的塑料制品,都可以使用热转印,只要表面光滑平整,并使用特殊胶水,可以使图案和产品完美结合。热转印膜具有许多直接印刷不具备的功能,使用热转印膜和热转印机将优雅的设计转移到产品上,使产品成为高价值的商品。它可以提高质量,降低成本,增加利润。

齿轮联轴器

产品分类 : 齿轮

(1) Crowned tooth allowed larger tolerance in shafts and higher loads. (2) Special hardening treatment W/high strength and anti-abrasiveness. (3) Closed type coupling--easy lubricate & anti dust as well as no leakage. (4) The type of TIEN YI GEAR SHAFTS COUPLINGS had been successful the first processing, it must be done the second procedure heat treating again according to material. And it were given them more rigidly precise, increasing stronger tenacity. At last removing gravitation by striking-ball bearing when those steps all finished.

Euroflex-The Flagship Press

产品分类 : 柔版印刷机

The state of the art gearless flexo press and is one of the best valued gearless press on the market. As the flagship press is equipped with the highest automation, precision, stability, and cleaning technologies available. The press technologies along with its structural design allow for maximum press speed, working on the widest range of substrates. If you are looking for maximum efficiency and minimum human intervention, this is the press for you to customize. KYMC

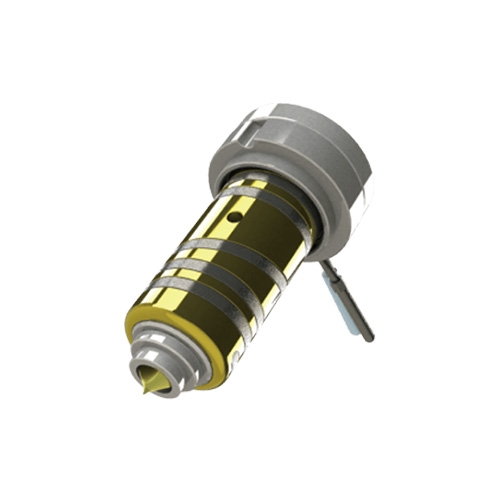

OPEN GATE-ANPT

产品分类 : 热流道系统

The most used nozzle. There is a torpedo inside the nozzle to have a circularity gate and guide the melt along the torpedo to flow into the cavity, and therefore can reduce the production of cool plug. Can reduce the cycle time due to the gate will cool down fast. It will be possible to have 4 seconds / cycle with excellent mold design. This series is very popular for unapparent gate mark. When the melt has added with glass fiber or is shear-sensitive and has strict requirement to the flow mark that will need more attention.

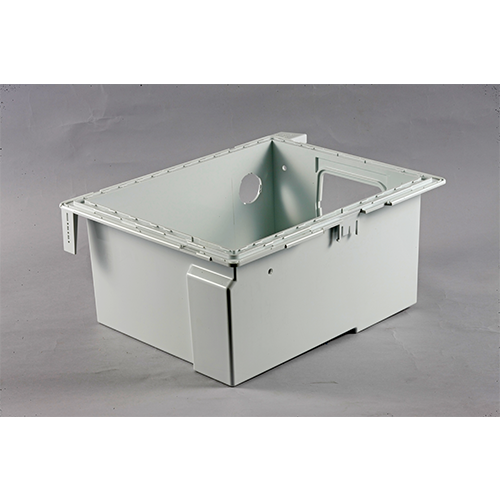

INSERT INJECTION MOLD

产品分类 : 注塑模具

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

UTS 650-1100

产品分类 : 工业机器人

Document management system installed for effective management of arm tooling Free encoding functions / 3D display showing parameters for the programmed stacking motion User-friendly encoding Built-in PLC software (LADDER diagram) An easy-to-use teach pendant