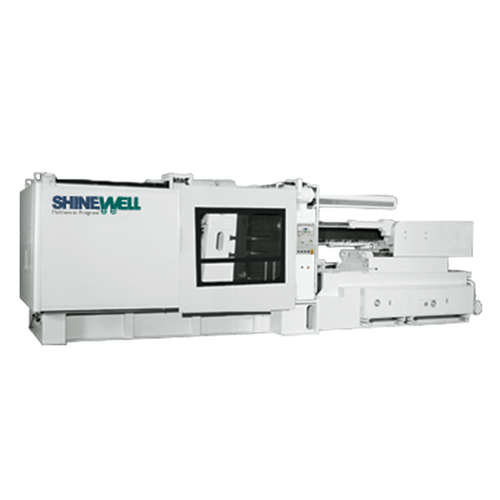

| Model | International Size | Theoretical Shot Volume | Clamping Force | Space Between Tie Bars | Mould Opening Stroke |

| 400MBE | 4000H-2045 | 1502 | 400 | 700x700 | 1500 |

| 500MBE | 5000H-2862 | 1910 | 500 | 780x780 | 1750 |

| 600MBE | 6000H-4462 | 2767 | 600 | 880x880 | 1800 |

| 850MBE | 8500H-4971 | 3613 | 850 | 1000x1000 | 2000 |

| 1050MBE | 10500H-7746 | 4752 | 1050 | 1100x1100 | 2350 |

| 1450MBE | 14500H-9614 | 7433 | 1450 | 1300x1300 | 2460 |

| 1850MBE | 18500H-15369 | 11486 | 1850 | 1600x1600 | 2600 |

| 2300MBE | 23000H-25143 | 18158 | 2300 | 1800x1800 | 2800 |

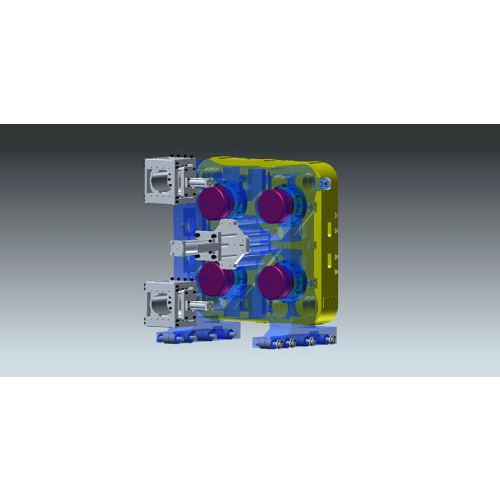

DIRECT CLAMPING FORCE BUILT UP BY MULTIPLE CYLINDERS

The actuator of the clamping force is installed on the fixed platen of the conventional two platens injection molding machine. The design of the MBE model has four sets of traveling cylinders inside of the movable platen to close the mold and to build up the clamping force at the center of the platen. Thus, the force is distributed evenly on the platen and creates zero deflection when the injection force activates. The clamping force makes a full release before the mold opens, so there is no issue of failed opening such as a mechanical deformation of the toggle under the conditions of a long cycle. The standard feature of the proportional valve with LVDT feedback achieves high precision of mold open-end position.

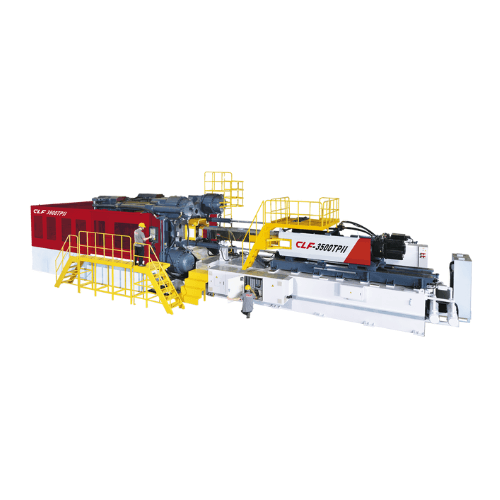

可依照开模行程和容模厚度灵活修改规格

开模行程长,适合生产较深长的产品,并可依特殊要求增加行程。机台容模厚度、托模行程及托模力亦可根据特殊需求作修改。使用两组快速油压缸做开关模动作,增加开合模速度;油压缸设置于操作面上侧,方便射出洗料或移除射嘴。

THE ZERO PLATEN DEFORMATION MAKES PERFECT MOLDING PRODUCTS

The clamping force is uniformly distributed at the center of the platen to perfectly keep the two platens parallel. The tie bars are forced averagely to each piece to avoid the issue of breaking. The clamping force release is either acting before the mold opens or before charging to reduce the time of pressure release. Simple and fast mold height adjustment. Only move the platen back by regular speed to the thickness that allows loading the mold and starts auto adjustment after installing the mold properly.

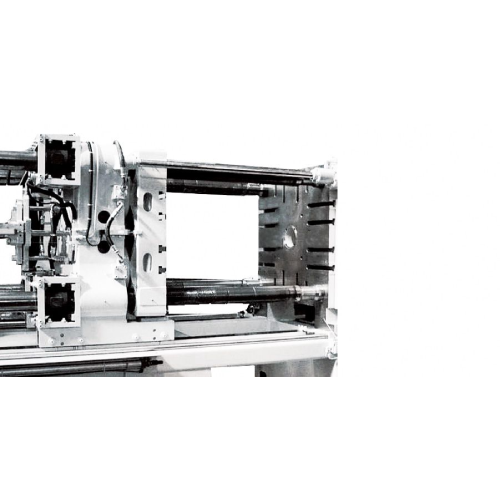

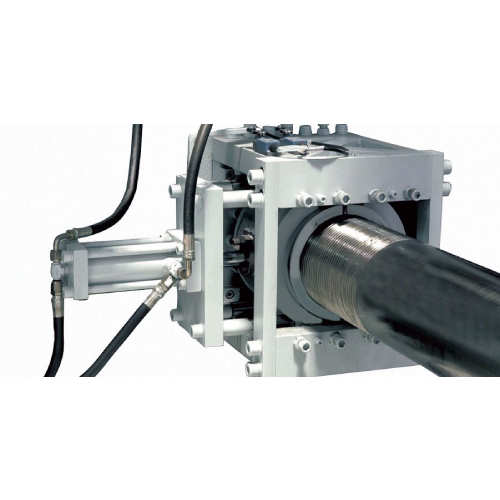

THE SPLIT NUT DESIGN OF THE LOCKING DEVICE SHORTENS DRY CYCLE

The split nut design of the locking device works for instant and precise locking force on the tie bar. Four sets of split nuts lock or unlock separately, and sensors monitor them simultaneously; once the motion is activated, the mold is able to open, or close.

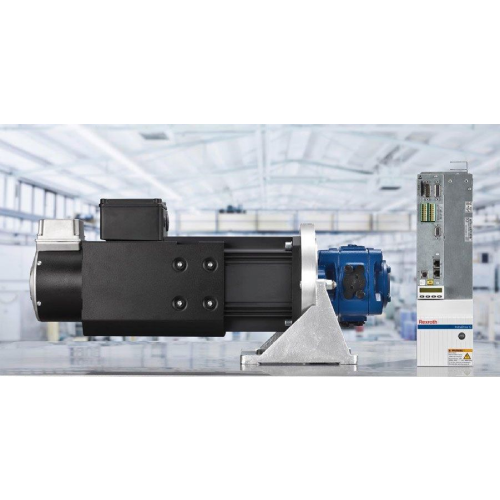

GERMAN REXROTHⓇ SERVO PUMP

The SVP system consists of one synchronous, controlled rotary-speed servomotor with a drive control section and an internal gear pump. The system software includes a set of closed loop pressure and flow controllers. Switching from flow to pressure control and backward is done automatically by the software. The controller has been optimized to avoid pressure overshoot while switching from flow to pressure control. For machines with a higher flow capacity, the Master-Slave system has one master servo unit combining single or multiple slave servo units that can provide sufficient flow for large machines.