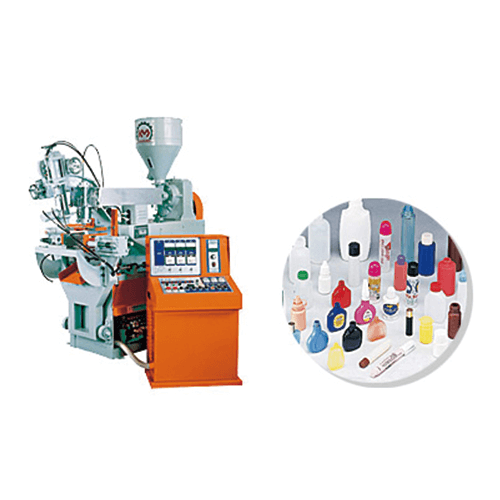

分类: 全自动押出中空吹气成型机

应用领域:

农业用品

各种瓶子 & 容器

汽车应用零件

建造材料

食物饮品容器

生活 & 化妆用品

生活 & 厨房用具

运动 & 户外用品

服装鞋类

农药瓶

清洁液瓶

洗手瓶

HDPE 盐酸桶

冰桶

桶子

润滑油瓶

油桶

油漆桶

塑胶瓶

滚珠球

滚珠瓶

薄壳容器

网球瓶

玩具盒

水塔

浇水桶

机车类零件

门框

乳制品瓶子

油罐/食物罐

PET 宝特瓶

塑胶杯

棒棒冰瓶

酱料瓶

水瓶

优格瓶

化妆瓶

睫毛膏瓶子

玩具

玩具外壳

沙滩桌

椅扶手

椅子

清洁用品

握把

栈板(组合型)

栈板(九脚型)

栈板(田字型)

塑胶餐具

收纳盒

桌椅组

垃圾桶

自行车零件

脚踏车车架

水桶盖

水桶

户外用品

EVA鞋

泡EVA鞋底

PVC鞋

| 型号 | FS-40 PSSO | FS-45 PSSO | FS-55 PSSO | FS-65 PSSO |

| 样式 | 单模头/ 单模架 | |||

| 使用塑料 | PE/PP | PE/PP | PE/PP | PE/PP |

| 螺杆直径(m/m) | 40 | 45 | 55 | 65 |

| 螺杆比例(L/D) | 24/1 | 24/1 | 24/1 | 24/1 |

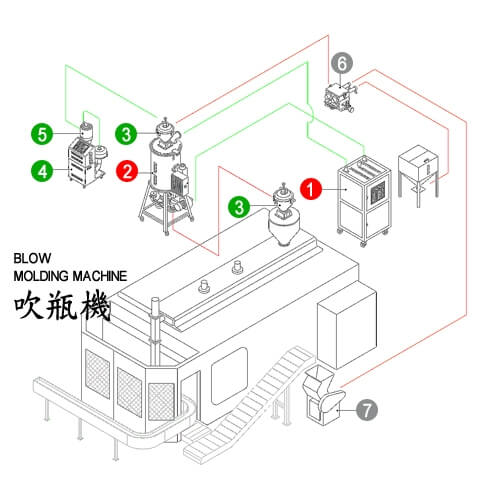

● 曲臂式锁模机构,配合德制线性滑轨为基础滑动运作,移模迅速且稳定性高。

● 螺杆传动方式采直结式德制齿轮箱搭配变频马达驱动,此为省能设计。

● 仰头式模头作动方式,使下料迅速,避免沾黏模具,缩短生产时间并方便校正调整。

● 吹气座配置快速移动变换位置功能,以油压马达驱动,以利模具更换、节省时间,此功能属创新便捷设计。

● 吹气系统加装瓶口微抽装置,使小瓶口口径成型更精准。

● 选配移模加装伺服马达搭配闭回回路(CLOSE-LOOP)系统,定位准确。

● 螺杆传动方式采直结式德制齿轮箱搭配变频马达驱动,此为省能设计。

● 仰头式模头作动方式,使下料迅速,避免沾黏模具,缩短生产时间并方便校正调整。

● 吹气座配置快速移动变换位置功能,以油压马达驱动,以利模具更换、节省时间,此功能属创新便捷设计。

● 吹气系统加装瓶口微抽装置,使小瓶口口径成型更精准。

● 选配移模加装伺服马达搭配闭回回路(CLOSE-LOOP)系统,定位准确。

EXPOSITION OF FULL SHINE'S MACHINE MODEL

| SCREW DIAMETER(M/M) | MACHINE SERIES | MOLD HEAD(DIE HEAD) | MOLD STATION | PRODUCT TYPE |

| FS-40 | (H) Horizontal | (S) Single Mold Head | (S) Single Mold Station | (O) Original |

| FS-45 | (P) Parallel | (D) Double Mold Heads | (D) Double Mold Stations | (C) Two Colors |

| FS-55 | (O) Standard / Oblique | (T) Three Mold Heads | (D) Two Layers | |

| FS-65 | (A) Pneumatic | (F) Four Mold Heads | (T) Three Layers | |

| FS-75 | (L) Frontal | (E) Eight Mold Heads | (F) Four Layers | |

| FS-80 | (I) Lateral | (L) Six Layers | ||

| FS-90 | (V) View Stripe | |||

| FS-100 | (P) PC baby bottle | |||

| Example | ||||

| FS-65 | P | D | S | D |