PROCESS OPTIMIZATION

产品分类 : 注塑模具

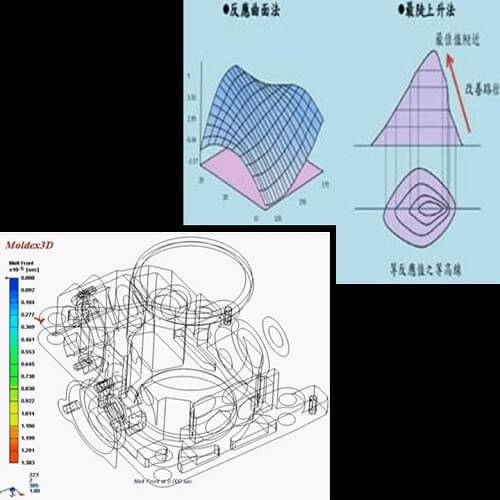

In-Mold Decoration (IMD) is an efficient, durable and cost effective technique for printing, painting, and forming plastic decorations. However, a large number of parameters involved IMD manufacturing processes and the complex relationship between these parameters make the determination of the optimal parameter setting a challenging task. This paper proposes a systematic framework integrating Response Surface Methodology (RSM) and logistic regression to improve the yield of IMD manufacturing process. The integrated framework becomes easy to identify the optimal parameter setting,saving a great deal of time and money in the manufacturing process. On the empirical study in collaboration with Yomura, the proposed framework shows the significant result from 10% to 87.5% validating the viability of the proposed framework in real setting. (Key words: IMD, In-Mold Decoration, Parameter Optimization, RSM, Response Surface Methodology, Logistic Regression) EXPERT ANALYTICAL SYSTEM Yomura Technologies employs state-of-the-art technologies to select materials, validate component designs, develop tool designs and optimize its processes, ensuring that innovative concepts are achievable at the lowest cost of production. (Keywords: Moldex3D, Moldflow, PowerMill Pro, CAD system)

HDPE 单层系列吹膜生产线

产品分类 : 吹膜挤出机

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

雨鞋3D图协助讨论& ABS+CNC打样

雨鞋模具最令人头疼的部分就是【讨论】,过往是由2D草图讨论花纹,再拿参考的样品来辅助双方想像,然而雨鞋是由高变化曲率的曲面所组成,只由2D草图及样品辅助双方参考,想像必定会有出入,所以往往会造成模具已经完成之后,却又不断修改的问题发生,修改模具不仅耗时,且修改过的模具势必会影响其寿命以及品质。

内曲肘塑胶射出成型机

产品分类 : 卧式注塑机

CNT 系列是第一代傳統機台的延伸指標。透過不斷的研發、改進、成長,締造CNT 系列擁有更高效率、更佳穩定的性能。為迎合更多客戶不同的需求, CNT 系列除了擁有標準型,更有昇級型的加強設計,譬如CNT-A 〈快速射出機種〉、 CNT-C 〈全閉迴路高應答高速射出成型機種〉、 CNT -S/SD( 高壓高速高剛性機種) 、 CNT 電木機和三迴路機種等。

TripleR Oil Cleaner

产品分类 : 过滤器

Industrial oil filters from Japan with 50 years of experience, specializing in filtration of hydraulic oil, lubricating oil systems, oil cutting a solid-liquid separation By filtering particles and impurities in the oil to maintain the health of the system's oil, a wide range of products can be adapted to the use of the environment in various fields. Sales cover many countries around the world, improve the rubber and plastic industry, automotive industry, iron and steel, paper and other industries of the oil health condition.

RAPID PROTOTYPING

产品分类 : 热流道系统

With the advent of 3D printing, rapid prototyping can now be done quickly and affordably. YOMURA TECHNOLOGIES is equipped with a high end, Digital Light Processor 3D printer built by Carima, a South Korean company with over 30 years of optical manufacturing experience. Unlike Fused Deposition Modeling (FDM) 3D printing which heats a plastic filament then squeezes it through a nozzle to print one layer at a time, DLP uses a special light wave to activate a chemical reaction in a photopolymer resin which then cures into solid 3D object. DLP objects are smoother, more detailed and almost seamless, ideal for professional quality prototypes. 3D PRINTER SPECS Max Build speed: 30mm/hr Resolution: 1920 x 1080 Size: 200 x 112 x 200mm 245 DPI High-end DLP (Digital Light Processing) 12 micron engine enables a very fine prototype Very minimal material waste MATERIALS Acryl: Easy post processing and coloring ABS-like: Semi ABS durability Epoxy: Great durability Rubber-like: Elastic material Lost-Wax: Metal Casting

VTOZ系列精密立式螺杆式射出机

产品分类 : 自动注塑机

● 专利模组化三合一可更换滑板设计,一机多用途● 无分力射出机构让射出更精准● 专利设计辅助进料系统,贮料跟卧式机一样精准● 两板直压式四缸锁模机构● 专利辐射式力学范本耐用30年● 安全光栅及安全门双重防护● 智慧程式控制系统让射出更容易● 相对同规格机型,机台高度最低● 符合人体工学的工作台高度●电脑控温气冷式油冷却系统● 精密节能油电伺服系统

三层共挤FFS重包装吹膜机

产品分类 : 吹膜挤出机

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.