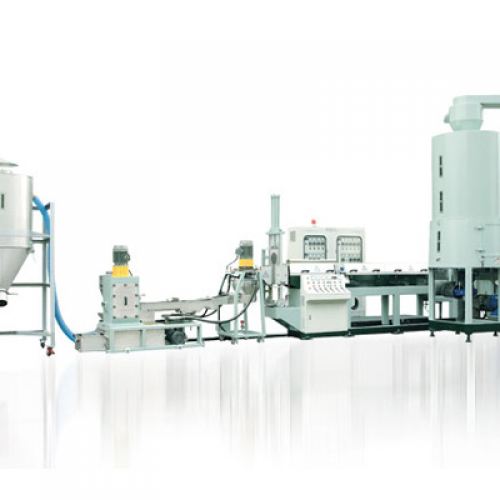

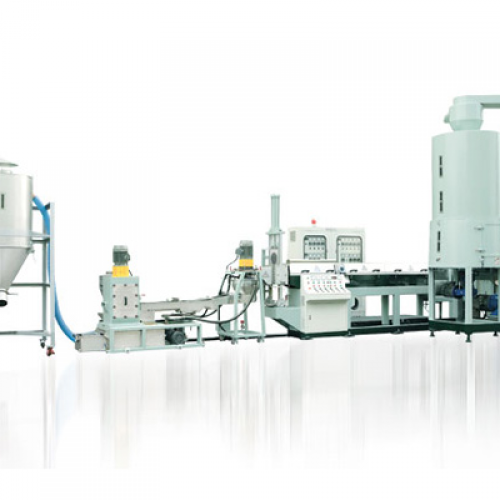

染色胶粒制造机(四色)

产品分类 : 塑料造粒机

• 型号: TY-DB 系列• 产地: 台湾• 适用树脂: PP,PE,ABS,PS • 特殊使用树脂: PC,PET,ACRYLIC,NYLON • 产能: 50~1000 kg/小时• 适用于胶粒染色使用。

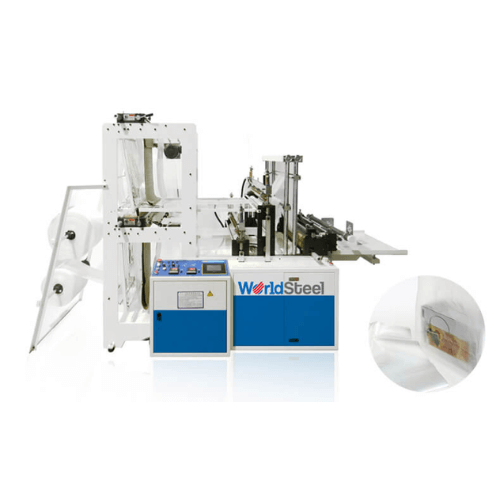

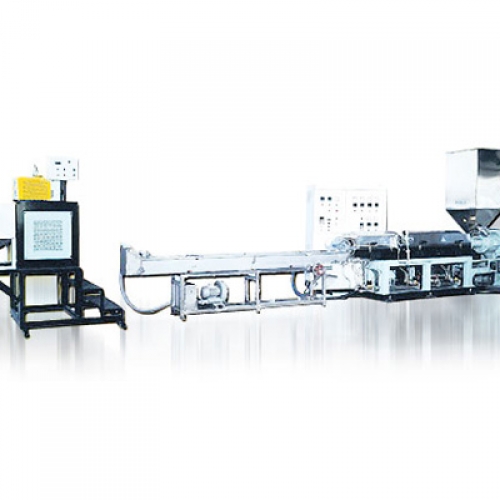

环保型双机直结模头切胶粒制造机(水冷式)

产品分类 : 塑料造粒机

• 型号: TY-LBW 系列• 产地: 台湾• 适用树脂: PP,PE,ABS,PS,HIPS. • 特殊使用树脂: POM,PC,ACRYLIC • 产能: 100~800 kg/小时

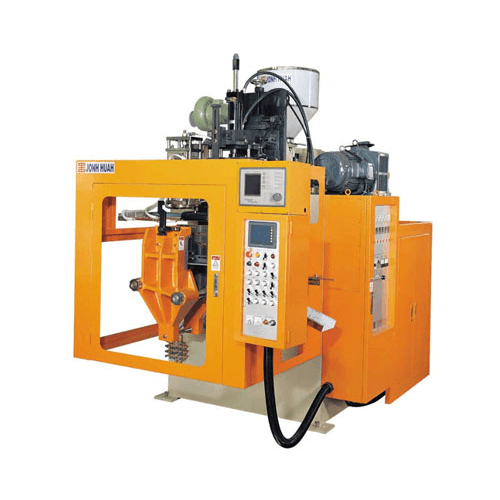

VERTICAL MICRO INJECTION MOLDING MACHINE

产品分类 : 微型注塑机

Quick and cost-effective mold solutions. Small order are available. (min. order of 300 shots) Product weight:From 0.001 gram to 8 grams. Product dilensions:From 1mm to 20mm. Materials:quality can vary from regular grade to engineering grade all kinds of thermoplastics, even high temperature resins. (Ex. PP,PE,ABS,POM,PA,PC,COC,LCP,PEI,PPSU and PEEK.)

DOUBLE INJECTION MOLDING

产品分类 : 注塑模具

Double Injection, sometimes known as 2 material 2 shot molding or 2K molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials. Through a highly specialized and automated process we carefully control the injection of multiple materials, including two different kinds of resin, into a single, multi-chambered mold. Double Injection in performed on one machine that is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The mold is then automatically rotated and a different type of plastic is injected into the mold from a second nozzle. Double Injection Molding optimizes co-polymerization of hard and soft materials to create powerful molecular bond. The result is a single part with production and feature advantages. It can be used for a variety of product designs across all industries. It also allows for molding using clear plastics, colored graphics and stylish finishes which improves your product functionality and marketplace value.

全电式射出成型机齿轮箱

产品分类 : 变速箱

三隆精心研制之射出成型机齿轮箱有效驱动射出机射胶螺杆。搭配平行入、出力轴之齿轮箱,依据客户个别需求,设计适合传动高扭矩力之齿轮箱,使齿轮箱具备极优异之低噪音、低振动特性。

PS、PC材质专用热转印膜

产品分类 : 薄膜

各类塑胶制品、布丁桶、容器、金属外壳、家用品、文具用品、礼品…等多项商品。各种PC和PS制成的塑料制品,都可以使用热转印,只要表面光滑平整,并使用特殊胶水,可以使图案和产品完美结合。热转印膜具有许多直接印刷不具备的功能,使用热转印膜和热转印机将优雅的设计转移到产品上,使产品成为高价值的商品。它可以提高质量,降低成本,增加利润。