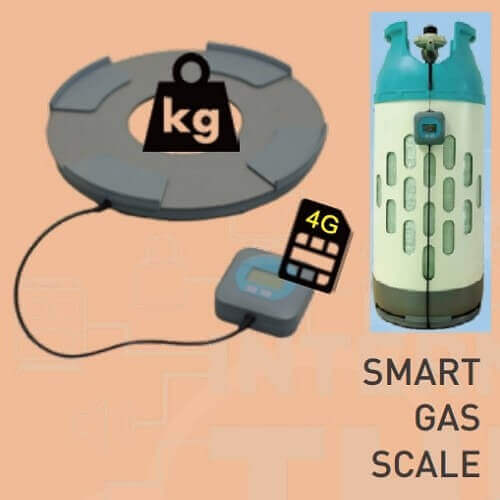

Smart Gas Scale for LPG

产品分类 : 指示器和传感器

立式关模立式射出机-YH系列

产品分类 : 立式注塑机

-四柱/垂直夹紧,垂直注射。 拉杆之间的矩形形状,易于插入。 -双注射气缸平衡,实现平稳,强劲的注射。 -结构简单,占用很少。 -双作用夹紧缸,用于快速夹紧,低速高压夹紧。 -单次滑动将下模推出,便于装卸。 -双重滑动使用两个下部模具,在操作员装载另一个模具的同时对零件进行机加工,以提高生产率。

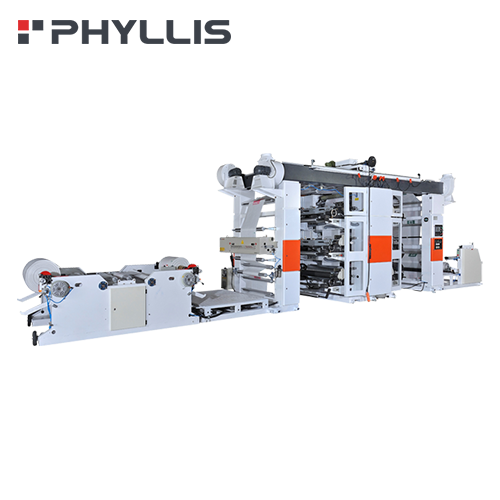

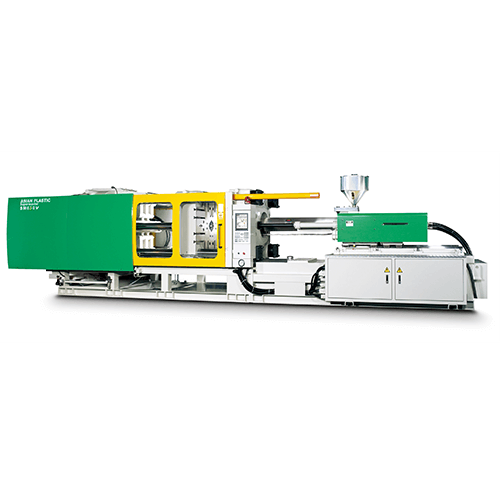

大型曲肘式伺服节能射出成型机

产品分类 : 卧式注塑机

• 超大的柱内距与容模量,固定板和活动板采有限元素法(Finite Element Analysis) 分析设计,以确保机械的强度及刚性。 • 采用双射移油缸可达到正确的模具对心效果,并可确保于高速高压射出时射嘴不会漏料。 • 线性滑轨射胶系统,减低机械耗损及背压产生,使产品射出更为精确。 • 采用BOSCH快速比例压力速度阀,此阀本身带有位置反馈,以及加装压力传感器,使得控制器所下达指令能够迅速反应回馈,达到敏捷精准的控制需求。

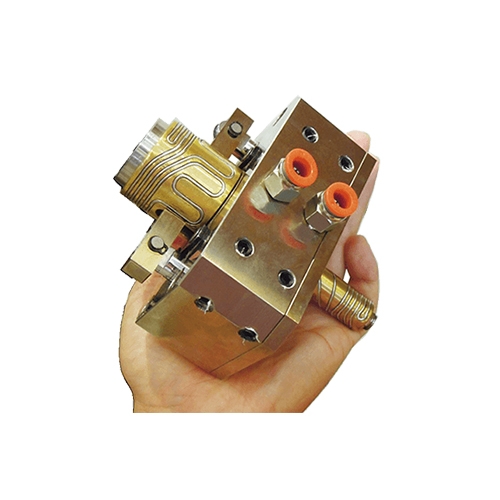

精密四柱式平面油压裁断机-CSS-202B

产品分类 : 发泡机械

●机械机体,使用特殊钢质制成,而且经过严格处理耐冲压,永久保持精密度。 ●上下行程采用钢柱为轨道,精密度高,永不摇晃。 ●两柱油缸,出力平稳,扭力大。 ●冲压时,有两段慢速功能,无震动,可减少裁垫损耗,产品无须边。 ●特有自动润滑系统,增长机械寿命。 ●工作物裁断调整器,简便,准确,10秒内可调整到适当深度。

高速曲肘式伺服节能射出成型机 (TSV 系列)

产品分类 : 液压夹模注塑机

特快锁模系统,采用油压差动回路,提高速度达60﹪以上,缩短周期,节省能源。 特殊无给油自润模板滑片,耐磨耐压,耐用性久。 自润铜司曲肘机构,确保机器之精度,可防止曲肘磨损。 采用BOSCH快速比例压力速度阀,此阀带有位置反馈,能够迅速反应回馈,达到敏捷精准的控制需求。 适用成型精密度高、薄壳成品之塑胶制品。 (成品厚度1 ㎜ L/t大于200) 蓄压器为选配装置。

Vertical Two Tie-Bar Injection Molding Machine

产品分类 : 液压夹模注塑机

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production, then reduce the cost of production. High precision mold platen (Parallelism/flatness:0.01/100mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact, space-saving design, reduce the heavy burden of the floor of factory.

Vertical Single Shuttle Table Injection Machine

产品分类 : 立式注塑机

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.