Success Story - PET Blow Molding Machines - Thailand

产品分类 : 电动中空成型机

CPSB-LSS6 high-speed blow molding machine

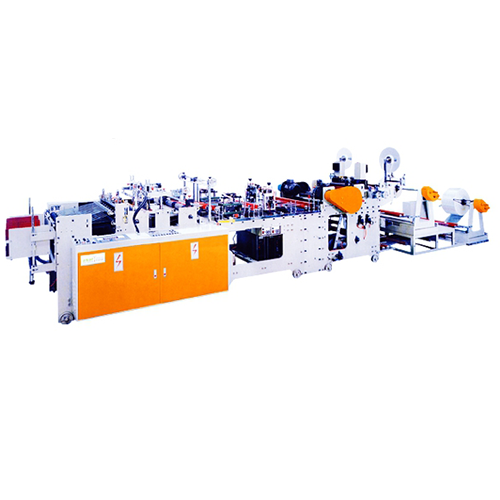

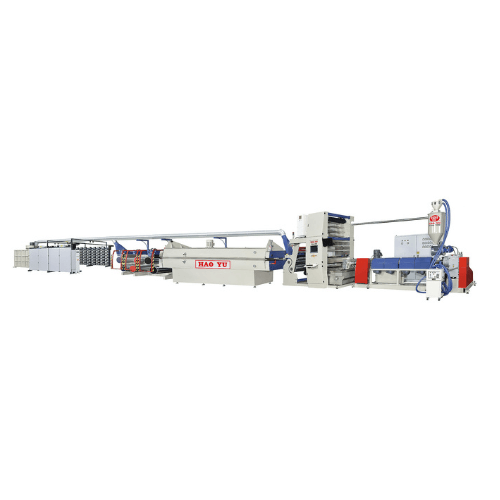

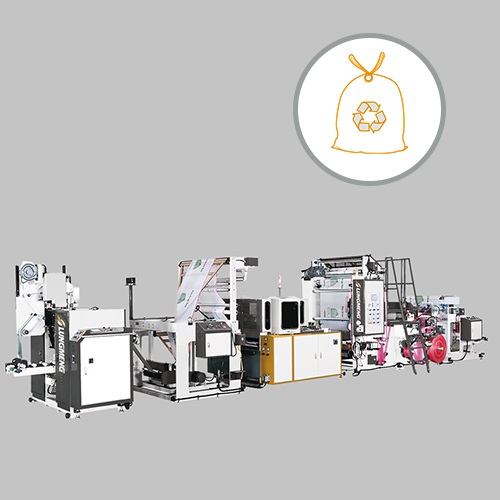

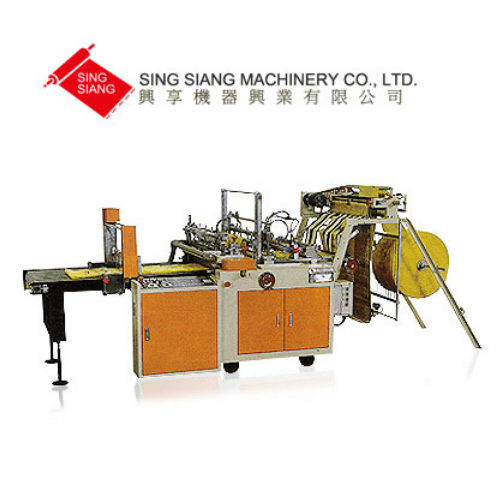

全自动高速单线有芯&无芯 ( V, C, N, M 折型) 平口卷取袋、卷取桌巾制袋机 / SMNRCR-1000

产品分类 : 塑料制袋机

全程电脑控制全程生产不停车配备张力自动配速补料自动停车:无原料、色检异常、塞料异常简易切换有芯无芯模式

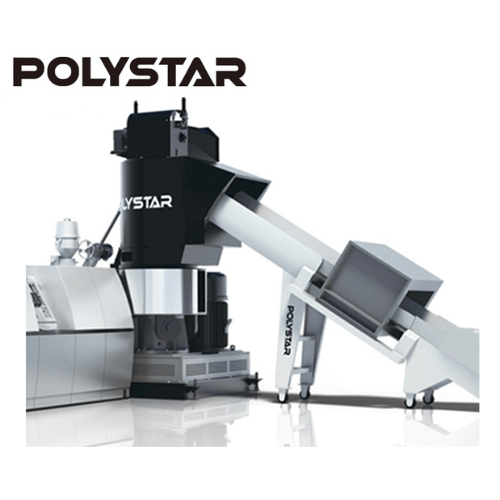

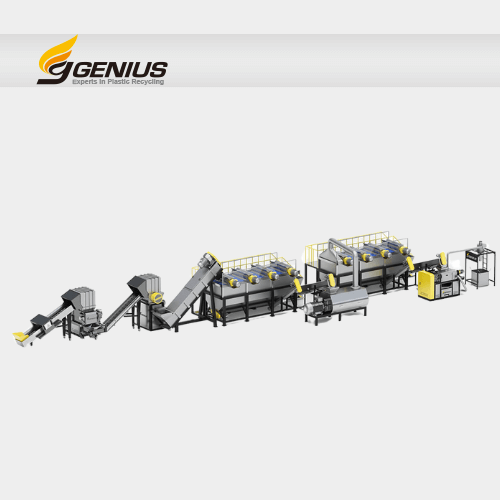

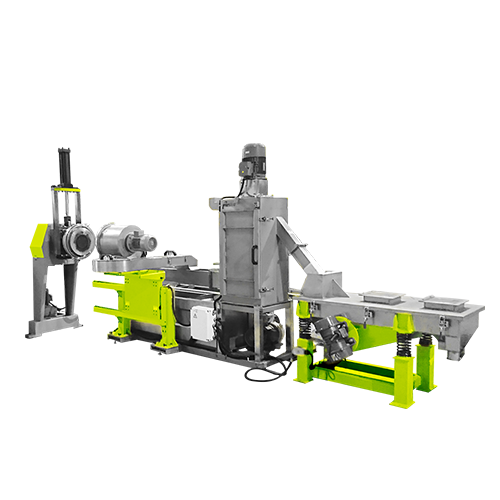

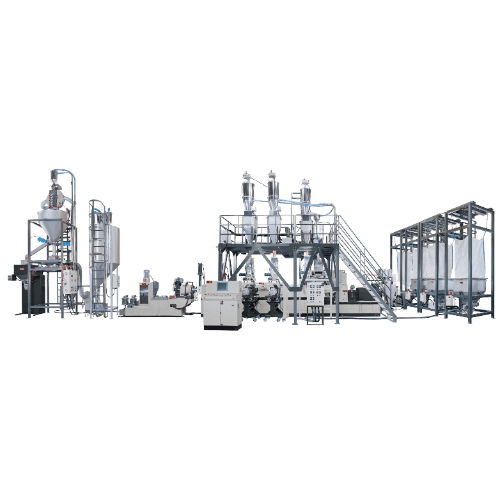

Side Force Feeder Type Recycling Pelletizing Extrusion Line | CK-SF

产品分类 : 塑料造粒机

CK-SF series Side Force Feeder Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic crushed films. Possible materials : EPE, EPP, EPS, PP, HDPE, LDPE, ABS, PS crushed films.

Hinged Container EG-88

产品分类 : 容器

Product Number: EG-88 Color: White Material: Fiber Shape: Clam shell

秤重式色母混合机SGD

产品分类 : 计量和测量设备

SGD秤重式色母混合机适用于色母或添加剂等的自动计量。该产品马达减速比为38:1,螺杆直径区分为12、16、20、30mm四种,可演变出四种机型提供0.04~60kg/hr的不同输出量供客户选择。 SGD支持挤出机模式,当用于搭配挤出机使用时,只需简单的线路调整,即可实现色母计量与挤出机螺杆转速的联动,保证色母的添加比例始终稳定。由于色母料的添加量比较小,其消耗量也较小,则可搭配正压空气填料机VL实现色母料的自动补充。

切粒系统: 水环( 模面)

产品分类 : 塑料造粒机

该系统由模头,水环室,切粒机,冲水流道,离心脱水机等组成,配合周边之循环冷却水系统组合而成。塑胶原料经押出机熔融出料,经由模头出料,在出料的瞬间,由高速旋转的切刀将塑胶切割,切割后的塑胶粒被甩落下方,由水环室内循环水膜带走并冷却,经由冲水流道带向离心脱水机,可以防止粘附塑胶颗粒,同时将塑胶颗粒冷却,此切粒之塑胶粒一般成圆扁状、圆柱状、圆球状。此系统特别于模面不与水接触,刀具模面运转耗材成本较低,且通过水环(模面)切粒系统生产的颗粒形状和大小均匀。目前主要用于LDPE、HDPE、PP等塑料。

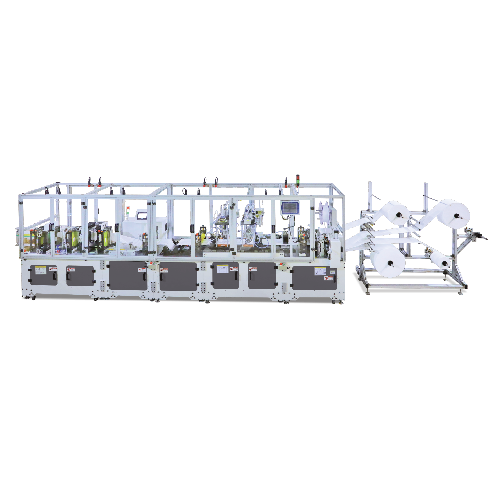

3D立体成人口罩制造机 (CE版本)

产品分类 : 制袋机按用途

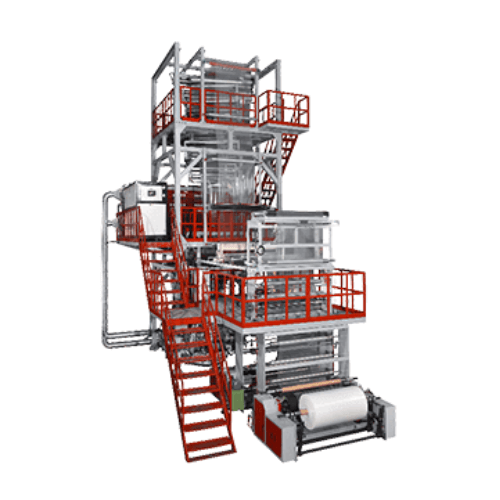

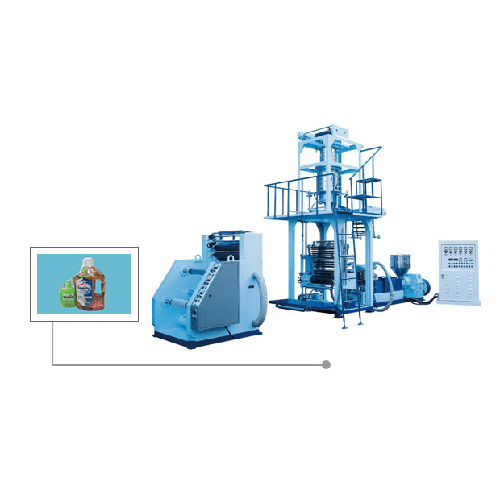

ABC三层共挤吹膜机

产品分类 : 共挤吹膜机

依托多年的擠出製造經驗,我們了解塑料吹膜擠出製程的各項原理,我們具有吹膜生產線的製造能力。此外,富隆的塑膠吹膜機,是依據原料特性及最終應用而量身訂做。在產品設計前,恆隆重視與客戶的溝通與討論,以建立與客戶的依賴。依據原料的用途,我們提供從 3 層到 5 層的共擠塑膠吹膜機。此外,最終產品在大幅降低成本的同時,也具備了所有所需的特性。

蜂巢式模具除湿机SMD-H

产品分类 : 塑料材料干燥机和除湿机

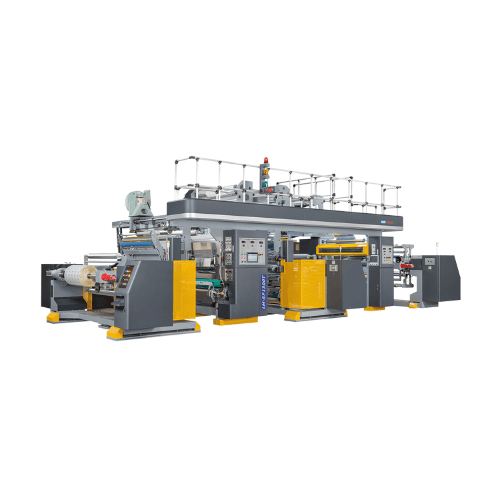

实用型分条复卷机- FSL-KA

产品分类 : 分切机和复卷机

专为各种软性包装材料设计如玻璃纸、PET、OPP、CPP、PE、PS、PVC及电脑防伪标签、电子电脑、光学机材、膜卷、箔卷、各种纸卷,胶卷及印刷后之各种材料之分条作业。

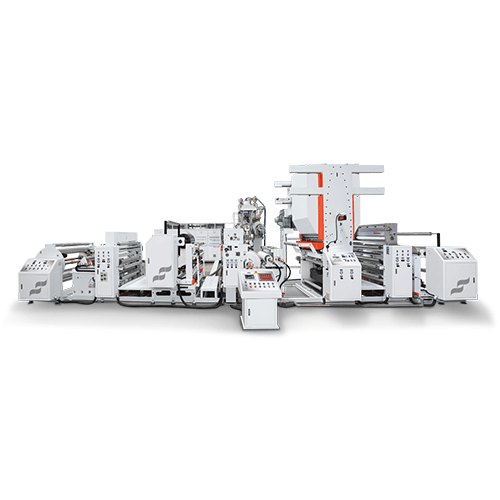

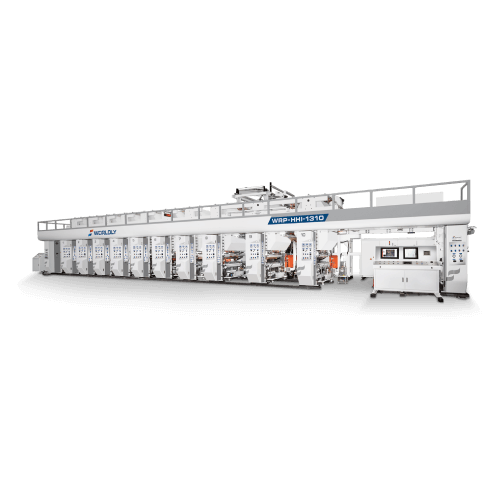

ELS独立马达高速型凹版轮转印刷机

产品分类 : 凹版印刷机

Ink resistance material of furnishing roller optimized ink circulation, avoid cylinder cell ink stock and improve printing quality. The roller driven by motorized can manual or automatic mode synchronized with printing speed. - Quick change over doctor blade holder design - Ink group trolley system for quick job change over - Centralized control system allow man power saving - Latest E.L.S technology

High Frequency Plastic Welding Machine KF-50

It offers an operating improvement By which it can save labor, operating time and money investment Besides it offers a convenient, fast and efficient production.

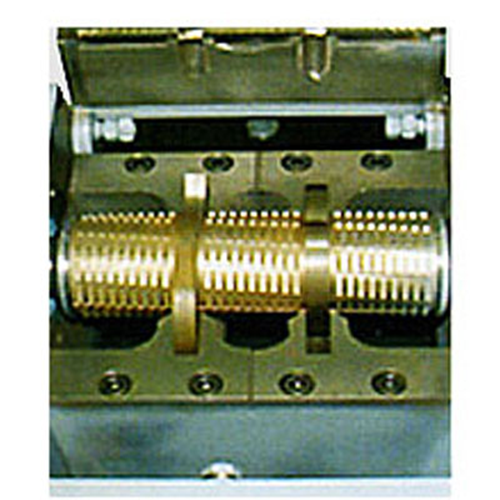

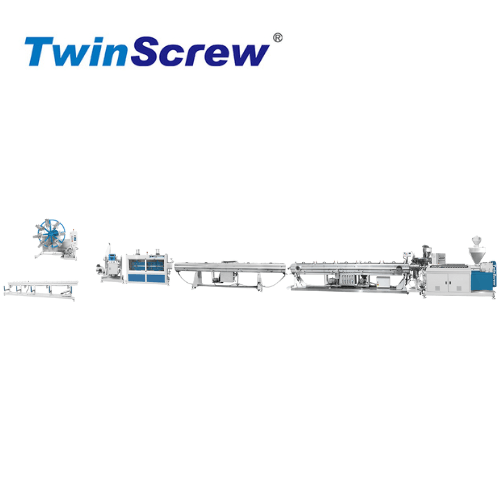

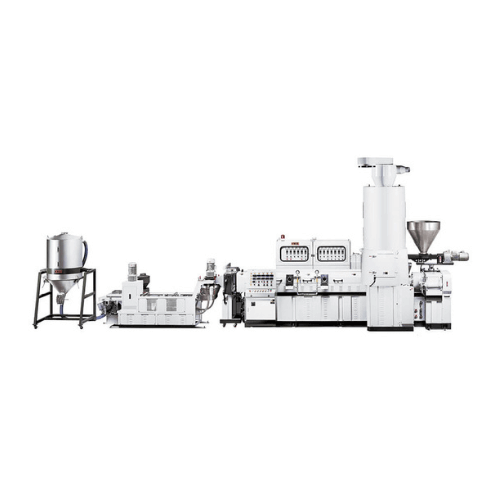

Co-rotating Twin Screw Automatic Metering / Weighing / Conveying Pelletizing Compounding Line | CK-HT

产品分类 : 双螺杆挤出机

CYKF is committed to the R&D and manufacturing of the automatic extrusion systems, and constantly strives for perfection. The CK-HT series Co-rotating Twin Screw Automatic Metering Weighing and Conveying Pelletizing Compounding Extrusion Line successfully overcomes the problem of customer limited site space and configures the optimal traffic line for customers. The high-efficiency system shows the advantages of safety, convenience, efficiency and quality, reflecting the greatest value of CYKF.

2米 半自动转印机 - 拉杆、自动喷涂-YHT-222AX

产品分类 : 水文/水传输机器

YHT-222AX是2米标准浸胶机,带生产臂,可手动或使用生产臂浸渍各种形状的零件; 该机器还包括一个自动喷涂系统,与这两个系统配合使用,可为最终产品提供稳定的质量。 温控罐满足介质容积要求。 高耐用性的罐体结构,重载生产臂和双过滤系统的水循环是您水转印业务的最佳工作工具。 这种转移印花机非常适合大产品和中等数量的生产/天。

微量型除湿干燥机 (DHM-SL)

产品分类 : 塑料材料干燥机和除湿机

运用空气压缩机之气体来干燥塑料,完成生产工作,空气压缩机产生之风量适合3C产品细小零件的生产,完美的干燥程度加上适度的干燥风量,生产效益大加分。 空气经过空气压缩机滤水处理,并在5~7kg/cm2的压力下进行压缩,再经过分子筛使得干燥空气露点达-40 ~ -50℃以上,让塑料于成型过程中,充份展现塑料完美的物性。依照塑料种类不同,所需干燥时间也略有不同,为2~6小时之间。 1. 搭配晏邦专为少量生产设计的空气填料机(AL)、料斗干燥机(HD)及热风回收器(HRC)即为同时具备干燥、除湿及输送三大功能的干燥专用机,经济又实惠,相较于一般除湿干燥机,此机型体积轻巧可直接装置于成型机之入料口,或将控制器与筒身分开放置,而干燥后的原料直接投入生产,避免原料回潮,确保生产质量。 2. 露点侦测显示 3. 空压源不足检测 4. 内建正压输送系统 5. 防超温保护器 6. 一周型定时器 7. 加装高密度过滤器 8. 具备工业4.0功能,可利用以太网络及RS485与其他品牌连结 9. 控制器与主体可采分离或合并,便利于空间安排

Vibration Welding Machine HWV-15LS

Vibration welding uses frictional heat to join the interface of two thermoplastic parts under mechanical pressure, the upper clipper clips the thermoplastic to do a high frequency reciprocating according the setting amplitude, it will have frictional heat generated to fully melt the interface, then stop moving and continued to put pressure and cooled to weld two thermoplastic parts

薄膜砂光机(WSF系列)

产品分类 : 分切机和复卷机

WSF系列砂光机可以在薄膜上产生刮痕效果。特别是在金属膜上。它可以像金属表面一样处理薄膜。每个金刚砂辊和清洁辊的速度均可单独操作,也可逆。快速释放装置可轻松取下滚筒进行清洁,并更换新的砂纸,而且除尘器可排出废粉尘,防止其在空气中扩散。

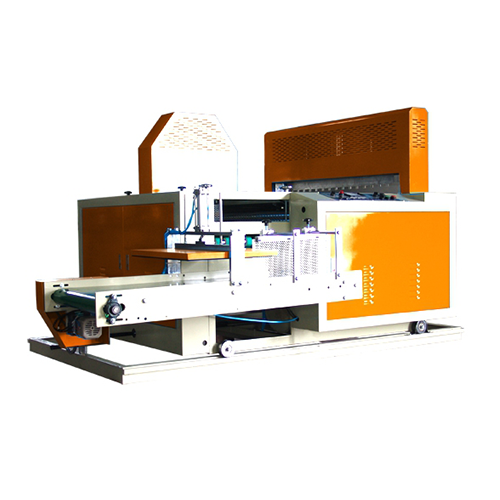

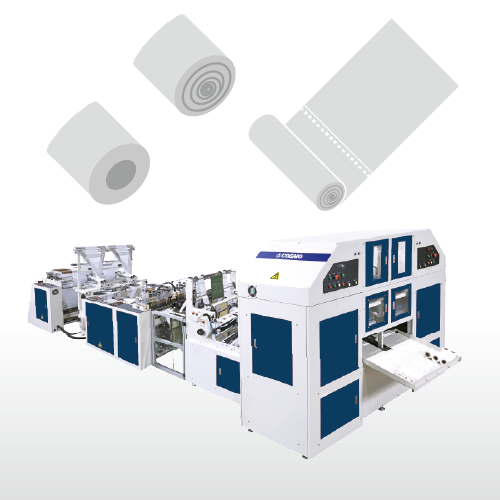

伺服马达驱动式电脑按键式普通袋专用自动封切机

产品分类 : 塑料制袋机

Servo Motor Driven Bottom Sealing Plastic Bag Making Machine Laundry Bag, Garment Bag, Calendar Bag, Glove Bag, Packing List Envelope, T-shirt Bag,

JS 336S PVC收缩膜制造机

产品分类 : 薄膜和片材挤出生产线

PVC Shrinkable file offer many excellent benefits, such as glossiness, high transparency, durability, water resistance and easy control of shrinkage. They have been applied to a wide variety of product packaging, such as foodstuff, beverage bottles, sporting goods, etc. For over 20 years, jumbo Steel has dedicated itself to the research of production technology for PVC shrinkable film. We have made great improvements in product prescription and machine performance, upgrading the quality and efficiency of PVC shrinkable films.We have a strong background and engineering experience for whole-plant planning and equipment supply. Jumbo Steel PVC shrinkable film production equipment has been sold worldide, and has earned a reputation for its superior machine and outstanding production know-how. In addition to supplying the most dependable machinery, we also place emphasis on the technological support and complete production upgrades. This allows our customers to start up or resume production very quickly. Jumbo Steel has a proven tradition of pursuing excellence and improving the PVC Shrinkable Film industry, and it will continue to develop its engineering capabilities and raise industry standards.

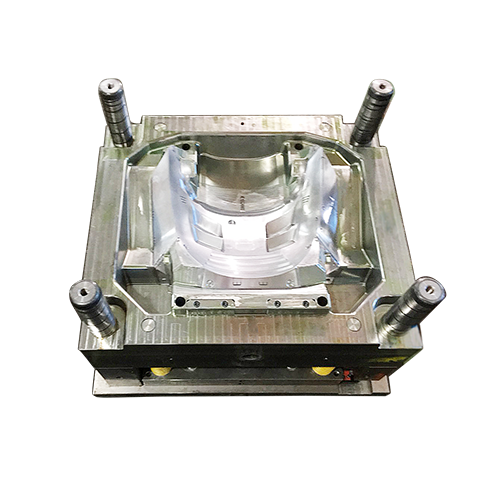

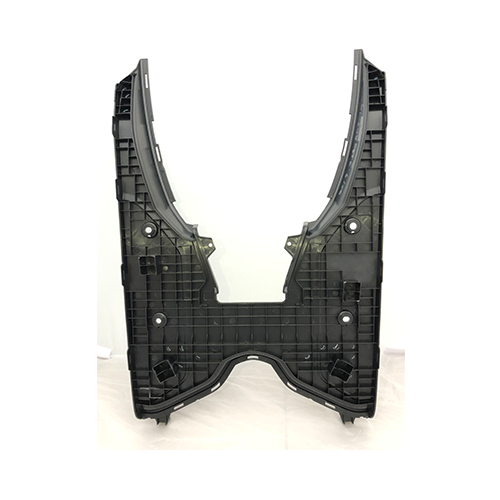

Insert Injection Molding

Insert Injection Molding Technology is a manufacturing process that integrates pre-placed components, such as metal inserts, electronic parts, or other materials, into a plastic injection mold. During molding, molten plastic encapsulates the insert, creating a single, durable, and high-precision component. This technology enhances product strength, reduces assembly costs, and improves reliability, making it widely used in automotive, electronics, medical devices, and consumer products. By ensuring strong adhesion between plastic and inserted components, insert injection molding enables lightweight designs, enhanced durability, and improved performance in various applications. Key Advantages: Seamless integration of metal and plastic components Higher product strength and durability Cost-efficient by reducing assembly steps Customizable for complex geometries Enhanced precision and consistency Common Applications: Automotive Parts – Armrest trim panels, dashboard components, connectors Electronic Components – Connectors, circuit boards, protective casings Medical Devices – Surgical tools, sensor housings, implantable components Consumer Goods – Power tool grips, ergonomic handles, durable casings