冲床专用快速换模系统争取换模时效、确保操作安全,少量多样生产已成目前产业的生产趋势,面对高频率换模时代的来临,具备高效率的换模作业能力已成为自动化生产过程中的重要制程,同时也是决定降低生产成本与提升市场竞争优势的重要依据,其中,「快速换模系统」在整个自动化生产中扮演着极重要的角色。

富伟冲床快速换模系统包含移模臂、夹模器、举模器、操作箱及动力泵组合。透过自动化设备的搭配,将模具的产品换模时间、生产启动时间或调整时间等尽可能减少,使用者能够快速更换模具与夹紧模具,减少换模时间、多种少量的生产、减少存货、产量与品质改善、降低劳力成本,彻底的降低换模时间,获取直接效益。

多台冲床共用一套快速换模系统整厂自动换模台车系统,该「自动换模台车系统」能有效解决3至15吨大型模具的换模作业,如汽车钣金、汽车保险杆、车灯、电冰箱、洗衣机、大型玩具等大型塑胶射出零件,且富伟精机可依各种独立作业需求研究开发各种搬运台车,并可设计单键全自动或半自动对模具的搬入搬出,同时,现在该模具输送系统也已逐渐被业者接受与采用,尤其是,汽机车零组件等需大型模具的制造业等。

富伟冲床快速换模系统包含移模臂、夹模器、举模器、操作箱及动力泵组合。透过自动化设备的搭配,将模具的产品换模时间、生产启动时间或调整时间等尽可能减少,使用者能够快速更换模具与夹紧模具,减少换模时间、多种少量的生产、减少存货、产量与品质改善、降低劳力成本,彻底的降低换模时间,获取直接效益。

多台冲床共用一套快速换模系统整厂自动换模台车系统,该「自动换模台车系统」能有效解决3至15吨大型模具的换模作业,如汽车钣金、汽车保险杆、车灯、电冰箱、洗衣机、大型玩具等大型塑胶射出零件,且富伟精机可依各种独立作业需求研究开发各种搬运台车,并可设计单键全自动或半自动对模具的搬入搬出,同时,现在该模具输送系统也已逐渐被业者接受与采用,尤其是,汽机车零组件等需大型模具的制造业等。

FORWELL Q.D.C.S冲床专用快速换模系统,为各式冲床模具提供多样性的快速换模专用元件,此系统的使用不仅可以降低冲床的闲置时间,还可以大大促进产能的提升,从而实现生产管理的更合理化。

这种快速换模系统具有多种功能,可以在不同的生产条件下使用。例如,当需要在短时间内生产大量不同类型的产品时,使用这种系统可以节省大量的时间和精力。同时,这种系统还可以帮助企业实现生产线的自动化,降低人工成本,提高生产效率。此外,这种系统还可以帮助企业提高产品的质量,减少生产过程中的浪费和损失。因此,使用这种快速换模系统是一个非常明智的选择,可以帮助企业更好地应对市场竞争和不断变化的消费者需求。

- 可以为各式冲床模具提供多样性的快速换模专用元件

- 使用不仅可以降低冲床的闲置时间,还可以大大促进产能的提升,实现生产管理更合理化

- 可以在不同的生产条件下使用

- 节省大量的时间和精力,特别是当需要在短时间内生产大量不同类型的产品时

- 可以帮助企业实现生产线的自动化,降低人工成本,提高生产效率

- 可以帮助企业提高产品的质量,减少生产过程中的浪费和损失

- 使用这种快速换模系统是一个非常明智的选择,可以帮助企业应对市场竞争和不断变化的消费者需求

| 导入前 | 导入后 |

| 1 手动操作。 | 自动化。工作效率更高,减少人力浪费。 |

| 2 在换模时,人力操作要花很长的时间锁紧。 | 在换模时,只需按操作板上的操作钮,快速而容易地锁紧。大大节省时间。 |

| 3 锁紧力道会因着不同的工作而有所差异。 | 新的设备可确保锁模力是一样的,从而可以更安全地进行操作。 |

| 04 现场人员花费很多精神,同时工安意外可能性增加。 | 只要透过操作板,现场人员不但可以节省人力,还能降低工安意外发生率。同时,新的设备也可以减少现场人员的工作强度。 |

| 05 螺丝松弛时没有安全警示。 | 新的设备具有安全警示功能,当有问题时,机台会自动停机,从而保障安全。 |

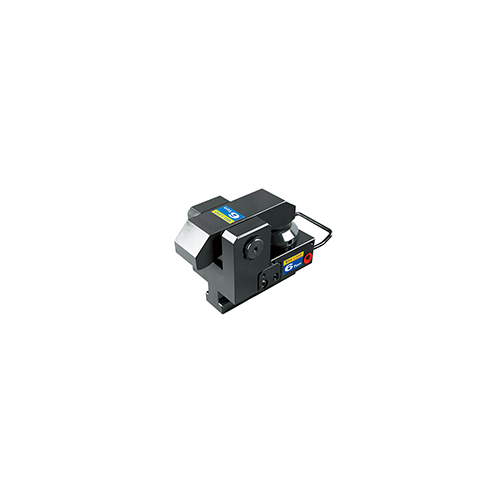

夹模器

移模臂(冲床)

操作箱

气动泵组合

举模器

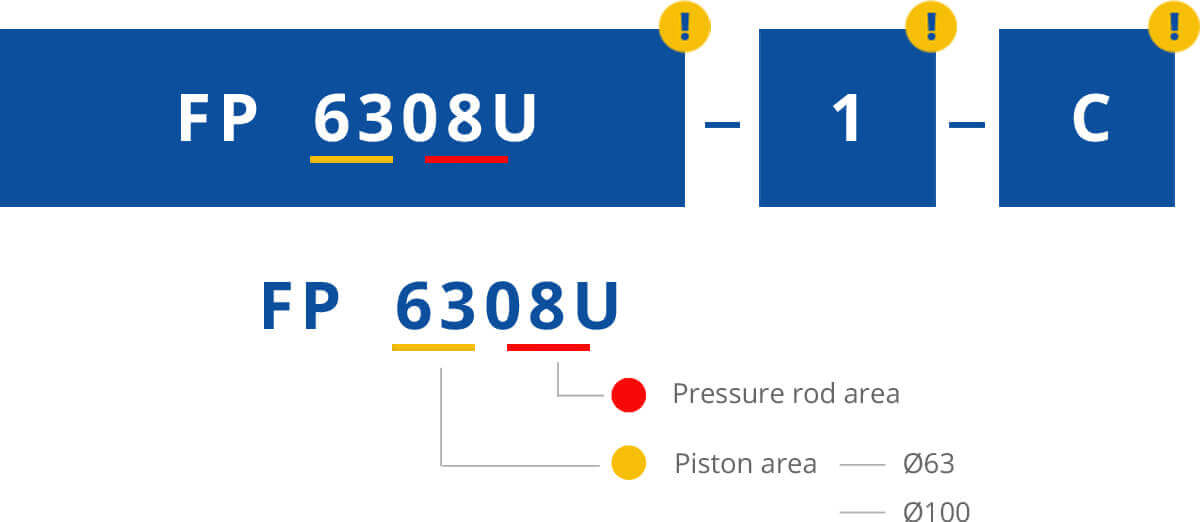

| 基本型式之选定 模具边沿有"U"沟设计,采用TX型 模具边沿无"U"沟设计,采用TY型 | 夹模器夹持力的计算 夹模器总夹持力= 冲床冲压能力20% | 上下模所需夹持力的分配 (上模夹持力):(下模夹持力) = 3:2 (单一夹模器夹持力)=(上模或下模夹持力) / 夹模器数量 若依所使用螺栓之规格推算夹持力,如下表: | 夹模器数量 根据模具的大小与冲床出力的吨数来决定 |

| 螺栓规格 | M16 | M18 | M20 | M24 | M30 | M38 |

| 夹持力(tf) | 3 | 4 | 5 | 10 | 15 | 20 |

上列夹模器夹持力与其数量应依实际作业需要修正,并且供夹模资模具边沿厚度须标准化,以利配合夹模器之使用

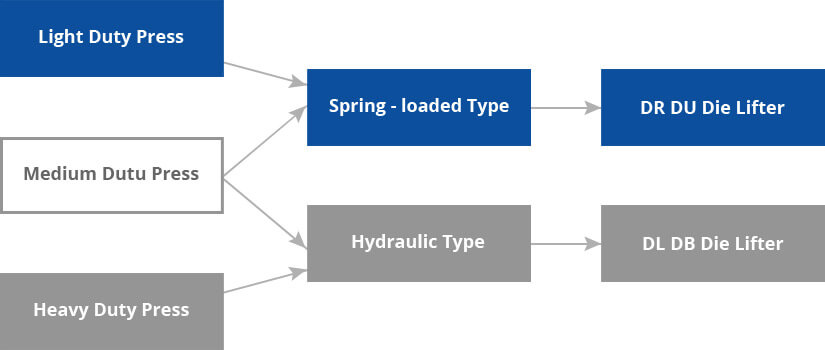

选择举模器

弹簧式或油压式之选定依据冲床吨数选择DL型(油压型)或DR型(弹簧式)此外并需将模具重量与所需举模器之长度一并考量

| 选用参考基准 |

举模器长度 |

举模能力 |

最大承载重量 |

U槽尺寸 |

配管配件 |

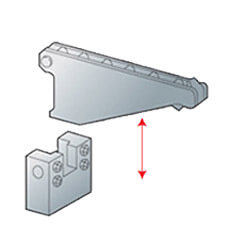

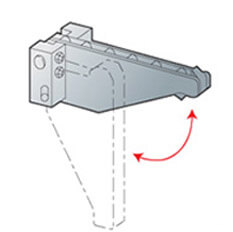

选择移模臂

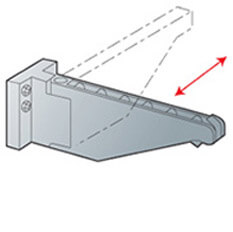

RC型(移动式)

RD型(折下式)

RE/RF (旋转式)

| 选用参考基准 |

模具尺寸 |

移模臂最大承载重量 |

型式 |