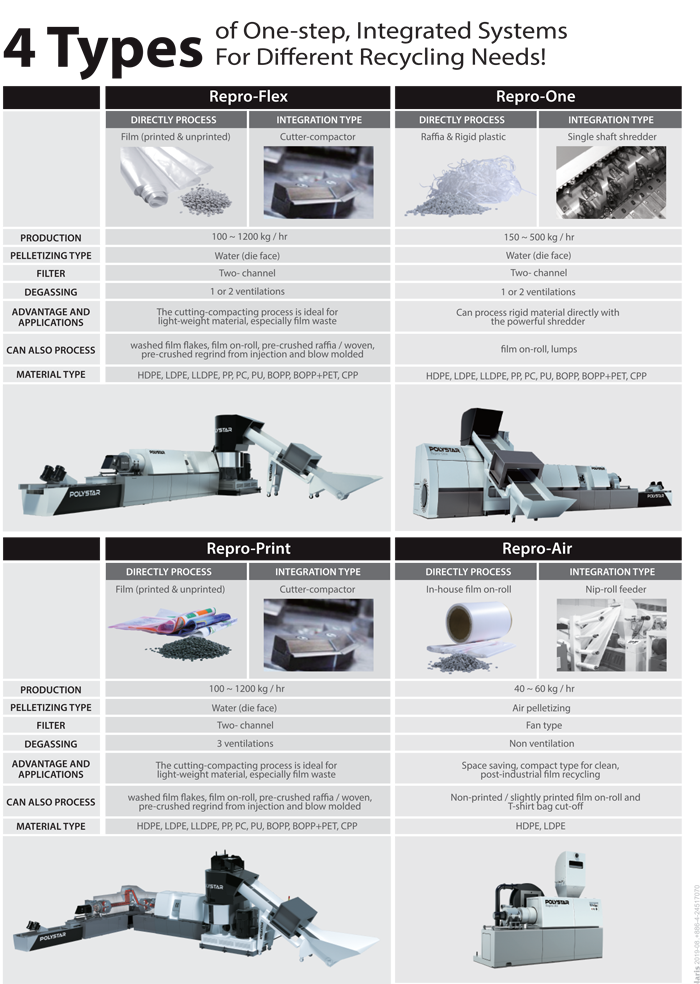

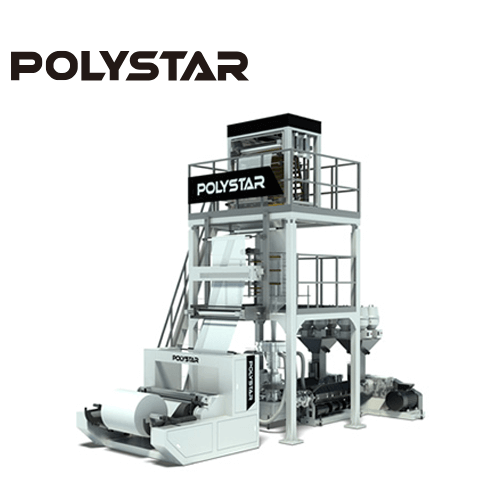

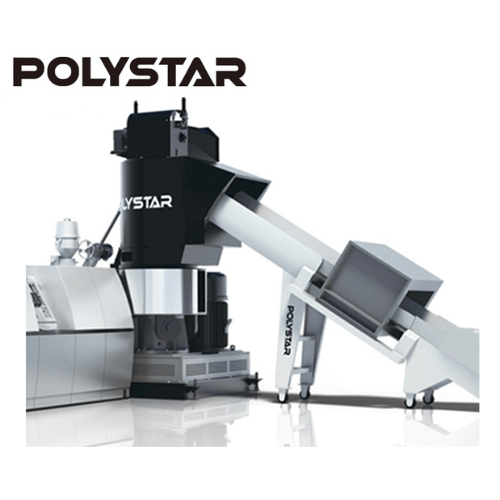

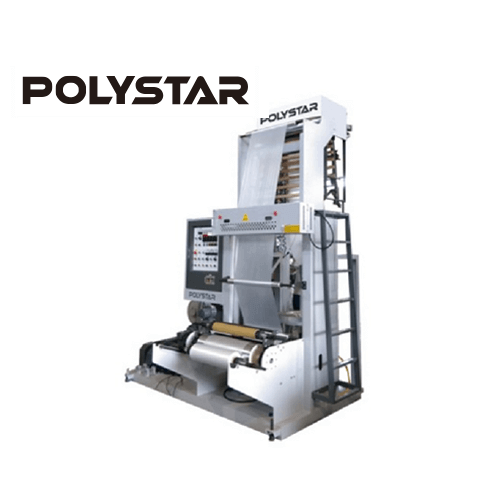

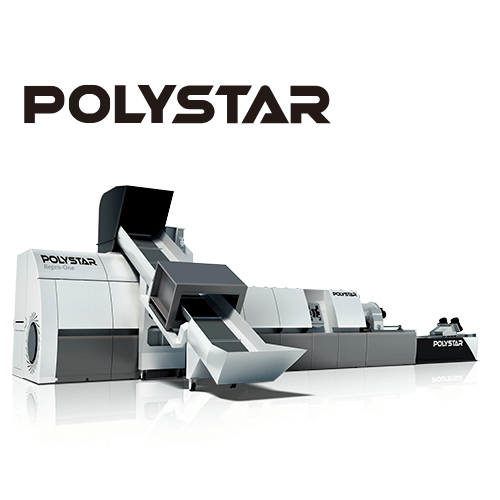

Air cooled type recycling machine for PE film and bag producers

1. Space-saving recycling machine Repro-Air has an average output of 40~50kg per hour, 800~1000kg per day.

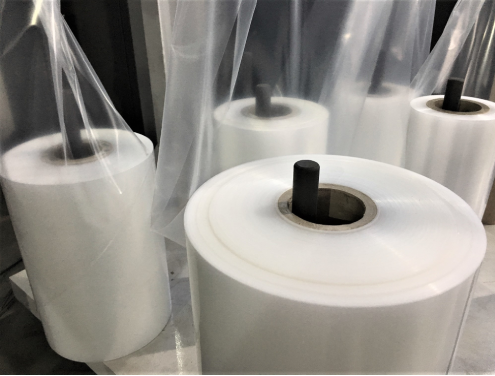

2. Through the nip roll feeder, the machine can process multiple film rolls simultaneously.

3. This air-cooled recycling line does not require any water consumption and takes up very little space, it can fit right next to or in between blown film machines. The machine dimensions are 2.5M x 2.5M x 2M.

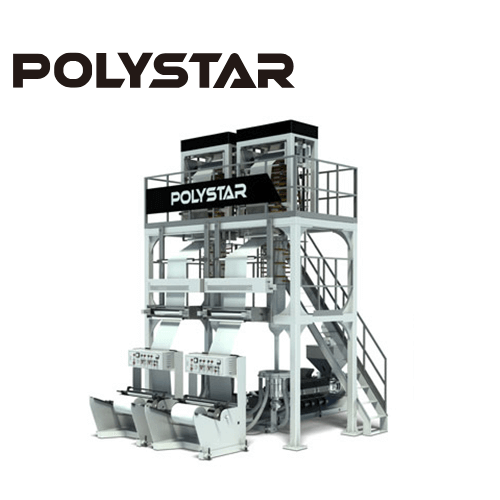

4. The model can effectively recycle HDPE, LDPE, LLDPE films from in-house production.

- Material type: HDPE, LDPE as optional with an additional die head

Film rolls

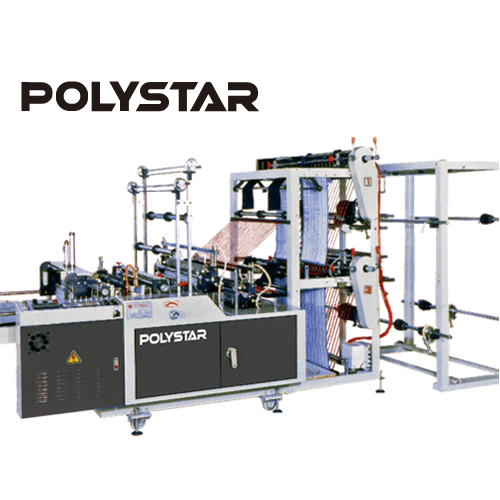

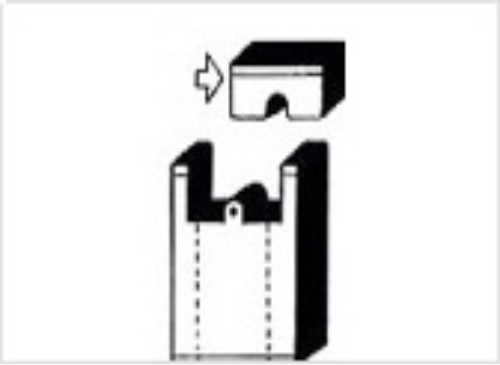

T-shirt bag cut-offs

Leno bags

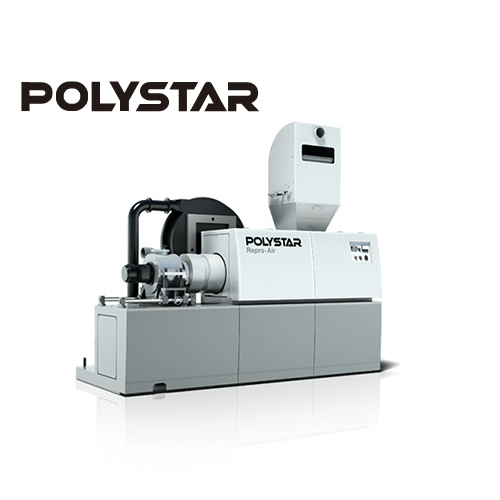

- 100% pellets re-usability right back into your production line

- Minimal material degradation without property change

- Reducing production cost by reprocessing your own industrial waste

| Model Name | Repro-Air |

| Final Product | Plastic pellets/granule |

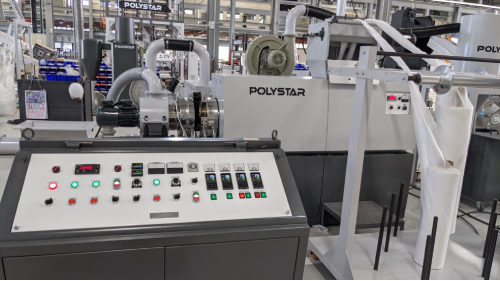

| Machine Components | Nip roller, force feeder, extruder, pelletizing unit, air cooling unit, silo tank |

| Recycling Material | HDPE LDPE as optional with an additional die head |

| Output range | 40-50 kg/hr *Based on post-industrial LDPE film clean, dry |

| Feeding | Nip roller for film roll feeding, force feeder for T-shirt bag cut off feeding |

| Screw Diameter | 120mm (customized) |

| Screw Material | SACM-645 (Customized bimetallic screw) |

| Degassing | Non degassing zone |

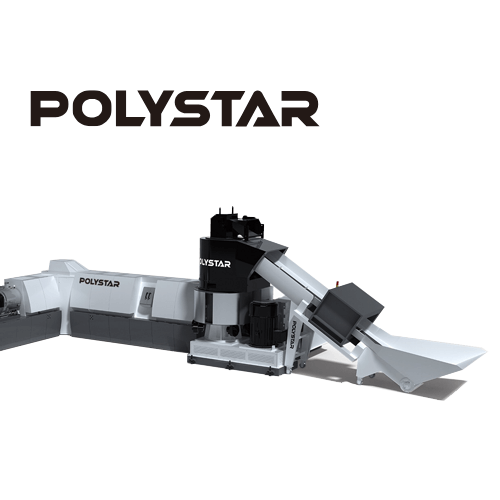

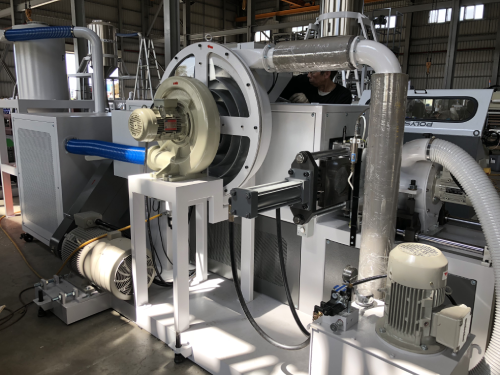

| Cutting Type | Hot die face pelletizing |

| Cooling | Air cooled |

| Voltage | Customized |

| Delivery Time | 60 days |

| Warranty | 1 year |

| Technical Assistance | Engineers available to service machinery overseas |

Output:

40-50kgs/hr

Repro-Air

In September, Polystar installed another air-cooling type plastic film recycling machine for the Sri Lankan plastic film manufacturer. The result is high quality recycled pellets. In addition, low maintenance requirement and processing stability of the Repro-Air is the reason why the Colombo-based plastic film producer decided to add its second Polystar with less than one year after the first installation.

Significant cost Reduction

This compact, air-cooling film plastic recycling machine is specially designed for blown film and cast film producers. The model can effectively recycle HDPE and LDPE film scraps, start-up or changeover film rolls (film-on-roll) without the need for pre-cutting, edge-trim waste, T-shirt bag bundles (cut- offs) from in-house production. Lightly-printed film can also be recycled into high quality, uniformed pellets. According to the film producers located in Colombo, Sri Lanka, the recycled pellets from the Polystar recycling machines are reused 100% in their blown film process. “We decided to go with Polystar because our experience with the company has been superb.”

The film manufacturer is now able to recycle almost all of its production waste to make pellets with excellent quality, from HDPE film scraps to LDPE film-on-roll– and considerably increase the percentage of recycled pellets in the end product (film). The advantage of this is higher production efficiency and with reduction in production costs.

Saving space and water

The space-saving recycling machine Repro-Air (economic type - RP120) plastic recycling machine has an average output of 30~80kg per hour, 800~1000kg per day. Through the nip roll feeder, the recycling machine can process multiple film rolls simultaneously. T-shirt bag bundles (cut-offs) from bag making process can also be thrown directly into the recycling machine without the need for pre-crushing.

This air-cooled plastic recycling line does not require any water consumption and takes up very little space, it can fit right next to or in between blown film machines. The pellets produced by the hot die face pelletizer are 100% dry and can be put directly back into the production line for immediate reprocessing. This plastic recycling machine is highly recommended for packaging film producers of different types of film and bags, such as flat bags, commercial bags, garbage bags, food packaging film, shrink film and many others.

Working principles

The space-saving plastic recycling machine Repro-Air (economic type - RP120) has an average output of 30~80kg per hour, 800~1000kg per day. Through the nip roll feeder, the machine can process multiple film rolls simultaneously with a precise control of material instake. T-shirt bag punches (cut-offs) from bag making process can also be put directly into the recycling machine without the need for pre-crushing.

After the hot die-face cutting, the air-cooled pellets are transported into a spiral device for further pellet cooling and separation. This special design allows the machine to effectively pelletize HDPE and LDPE with minimal material property change.

The compact design of the recycling machine is ideal for producers with limited factory space. The machine dimension (length x width x height) is 2.5M x 2.5M x 2 M. It is extremely compact and user-friendly, and does not require any installation (ready-to use) upon machine arrival. The average lead-time of a Polystar air-cooled recycling machine is only 45 days.

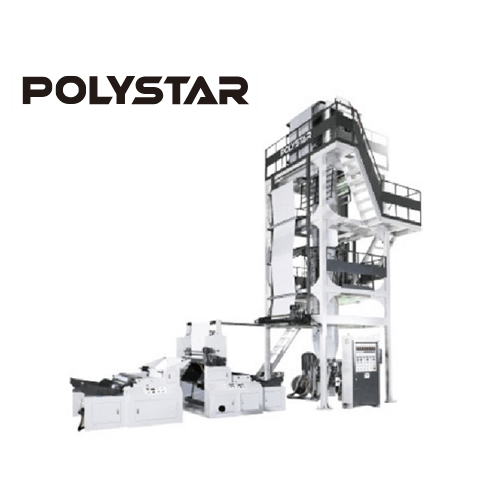

Perfect for film and bag producers of all sizes

Amongst all the Repro-Air machines that Polystar has installed worldwide, approximately 50% are for producers ranging from 100-300 tons/month, 35% are for 300-700 tons/month, and 15% are for producers over 1,000 tons/month who use the combination of Repro-Air and Repro-Flex. In the case of an Indonesia-based film producer who manufactures 2,000 tons of plastic bag per month, a combination of two Repro-Air, one Repro-Flex 120 and one Repro-Flex 85 are used, installed in different factories dedicated to reprocess different types of materials.

Though the production capacity is only 40-50 kg/hr for the Repro-Air line, it is still very useful even for large-scaled film and bag producers. For companies that have several factory locations or large factory areas, the Repro-Air can be placed in one of the factories or a specific factory area focused on recycling only one type of product, without having to constantly switch between different types of material and adjust machine settings.

Short delivery time. High return on investment

The average delivery time of the Repro-Air is only 30-45 days upon order confirmation, thanks to the highly standardized design in which Polystar always has under production. On average, the return on investment is only 6 to 10 months after the machine installation, proving that post-industrial recycling can be extremely cost-effective for film and bag producers when done correctly.

Videos of Repro-Air processing different materials:

Check out all the details of our Repro-Air Recycling Machine

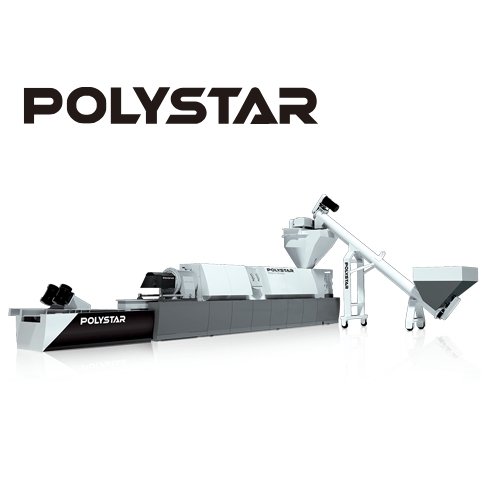

For recycling machine of bigger production capacity (100 kg until 1,000kg/hr), please see our Repro-Flex Plastic Recycling Machine

Work with POLYSTAR

An experienced market leader in the recycling field, especially for the recycling of packaging film

More than 1,700 Polystar plastic recycling machines have been installed worldwide since 1988

Proven success and positive feedback from satisfied customers in 105 countries

Flexible, personalized machine design to meet your specific requirement and factory layout

Top quality components used for the machines: Energy saving and high performance motors

Cost-effective machine: Lower investment cost for a high quality and durable machine

Service and Communication

Fast online trouble shooting