近期更新 立即订阅

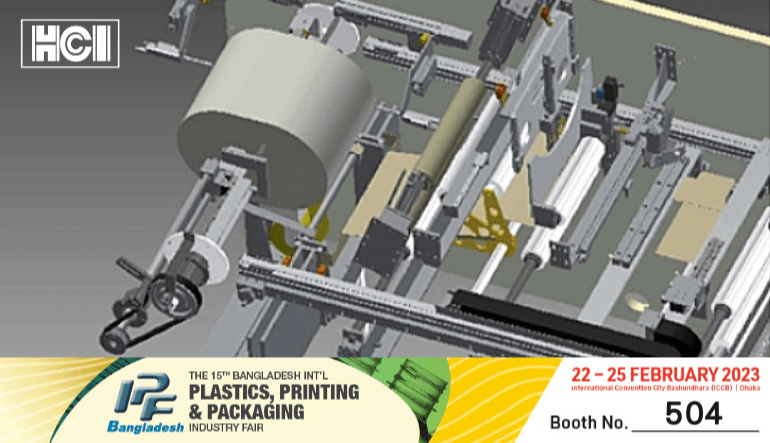

HCI: How to Rewind an Ellipse Shaped Product - Dare to Try Automated Process Solutions - Ellipse Shaped Reel Rewinder

A reputed professional filter manufacturer in Taiwan contacted HCI. They specialize in the production of corrugated axial air filters, and have obtained many patents in Taiwan, China, Japan, Germany and the USA. However, it encountered great difficulties in the rewinding process, because the finish product is an ellipse shaped reel. That's right, it is an [ellipse] rather than a round product that we are familiar with. At present, customers can only rely on manual equipment for several stages of production. Not only the production capacity is low, and not able to improve the yield rate.

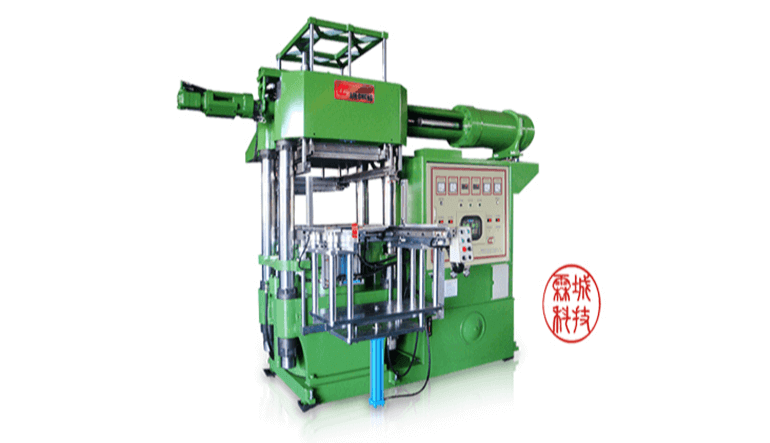

TungYu-Clean Room Vacuum Compression Molding Machine (CE)

TUNG YU has been dedicated to providing the most professional and complete compression molding equipment to customers worldwide for 40 years. In recent years, TUNG YU has also continued to refine technology and developed of compression molding machines that meet high precision details.

Cosmo: A professional manufacturer of plastic bag making machines

COSMO MACHINERY CO., LTD. has been founded in 2001 in Taiwan. Based on more than 20 years of designing and manufacturing experience, with ISO 9001 and CE standard, COSMO has been well-known as a professional manufacturer of plastic bag making machines from Taiwan. Up to now, we have extensively exported 3000 machines to 100 countries spreading all over the world.

JANDI’S: The Strength of JANDI’S with Successful Case Sharing

Mr. Samet AYDOGAN is the Export Director of AYDOĞAN Plastik which is based in Turkey. AYDOĞAN has been in the flexible packaging sector since 1988. They are a tailor-made producer who is addressing almost all sectors, starting from food, personal & home cares to textile and many others. As a tailor-made producer, they have to make all the choices available for their clients, and that is why they chose JANDI’S, we make their requirements come true!

How to Start Plastic Recycling Business? A Complete Guide to Choosing the Right Recycling Machine

Plastic recycling is a growing industry. There are numerous factors to consider if you want to start a recycling business. You must decide what types of plastics you will recycle, determine the location of your business, research local and state requirements, research your customers, set up accounts with plastic buyers, and, most importantly, invest in a reliable plastic recycling machine.

World Steel: Automation, Customization and Service Quality, the key Factors for Success in the Bag Making Industry

World Steel, is a leading manufacturer of bag making machines. The company has a reputation for providing high-quality machines that are designed to meet the needs of a wide range of industries. One of the key features of World Steel's bag making machines is their automation capabilities. These machines are designed to operate with minimal human intervention, allowing for increased efficiency and productivity. They are equipped with advanced technology, such advanced control systems, which allow them to operate at high speeds and with precision accuracy.

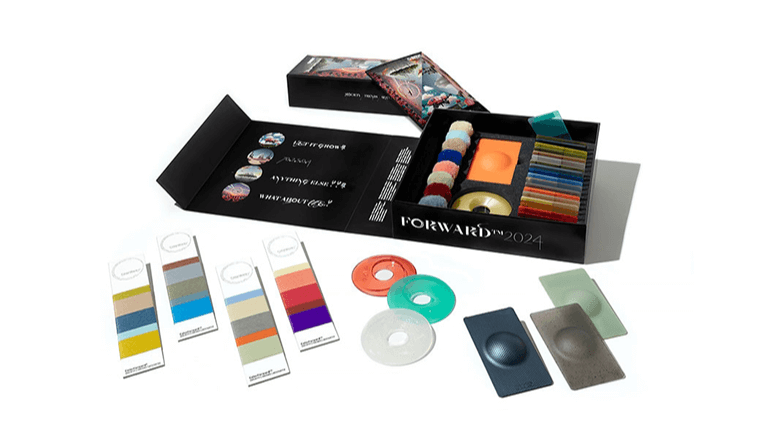

ColorForward™ Predicts 2024 Trends of More Harmonious Colors with a Splash of Exuberance

Avient Corporation today announced the release of ColorForward™ 2024, the annual color forecasting guide for the plastic industry developed by its ColorWorks™ team. Now in its 18th edition, the forecasting guide includes a palette of 20 colors and effects selected by a group of color, marketing, and social trend experts. This guide is created annually to help plastic product designers, brand managers, and marketing professionals make more informed color choices.

CHAO WEI: Fully Automatic Perforating Draw Tape Bag On Roll Making Machine

CW-1200PDR-SV series are coreless bags on roll making machine, mainly produce side sealed perforating draw tape bags on roll or bottom sealed bags on roll with 2 times folding by triangle folders. Machine is equipped with servo motors for stable and precise production, touch screens making bag length and speed settings simple and easy operation, German made photocell for bags with printing, German made E.P.C guiding system and servo controlled web auto tension for very smooth production.

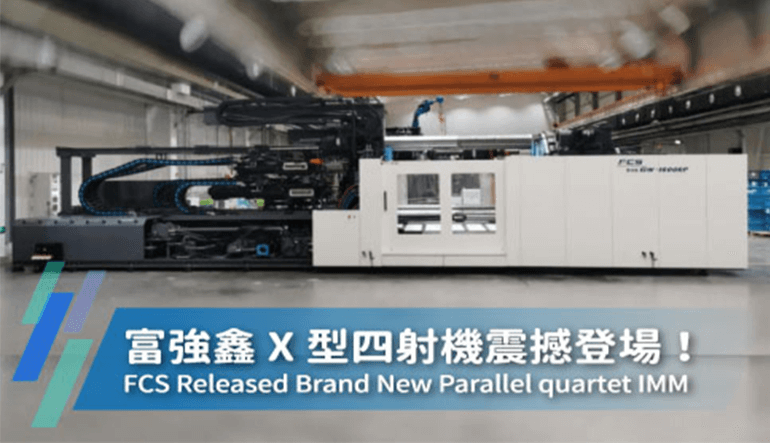

富强鑫多组分注塑机产品线又添新成员:X型四射机,震撼面世!

富强鑫多组分成型技术解决方案,增加全新成员:「X型四射注塑机」。该项技术已成功导入于富强鑫大型多组分注塑机产品线。首台GW-1600R大型二板式多组分注塑机(四射机),已顺利交付中国知名大型车灯供应商,实现产品量产。

Sustainability Benefits for Plastic Film Producers

Why do producers want to recycle plastics? Although plastic is a very popular material, on a global level, less than 10% of it is recycled. With plastic waste being in such a high supply, producers could benefit from incorporating recycling into their existing business model. A recent study by business and daily found that 72% of the respondents are actively buying more environmentally friendly products than they did 5 years ago.

BoReTech: How to Make Recycling Waste PET Bottles Easier and Produce High-Quality rPET?

The global brands announced they would give up using virgin plastics in their products, which means more recycled plastics and rPET is required in markets. More than 60 brands and retailers have set corresponding reduction targets on the use of virgin plastic. The new commitment proposes that by 2025, the absolute benefit of virgin plastic will be reduced by nearly 20% compared with 2018.

LIN CHENG: None Runner-Waste Rubber Injection Molding Machine

For more than four decades Lin Cheng Technologies has shown its great expertise around the world on creating exclusive services for customers. We stand out in the field for manufacturing rubber injection molding machines, silicon rubber injection molding, vacuum compression molding, thermoforming, thermosetting, carbon fiber molding, powder forming and other types of compression molding machines.