近期更新 立即订阅

BoReTech: Comprehensive Solutions for Plastic Recycling

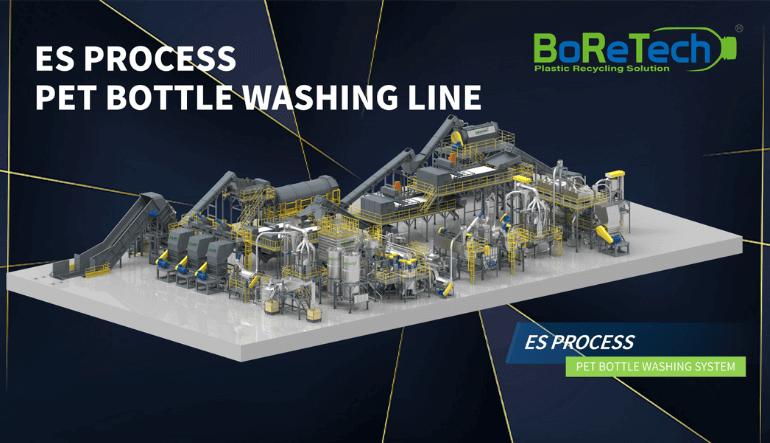

BoReTech is at the forefront of global plastic recycling, providing cutting-edge technology and comprehensive engineering solutions to enhance sustainability in the industry. With expertise spanning PET, PP, HDPE, and mixed plastic recycling, we offer a complete suite of innovative solutions designed to meet the evolving needs of recyclers worldwide.

BoReTech: Advancing Plastic Recycling Solutions Worldwide

BoReTech is a professional environmental engineering enterprise specializing in cutting-edge plastic recycling technologies and engineering. With a global presence spanning over 40 countries and regions, we deliver innovative plastic recycling solutions, including all kinds of plastic washing systems, like PET, HDPE, PP, PE, recycled polyester staple fiber equipment, and turnkey plant engineering services for bottle-to-bottle.

Shaping the Future of Plastic Recycling in the USA with POLYSTAR

The United States is putting more emphasis on sustainable practices. One area getting a lot of attention is plastic recycling, which is evolving rapidly in response to growing environmental awareness and shifting consumer habits. This industry is all about giving plastic waste a new life, from turning everyday items like used bottles, containers, and packaging into raw materials for new products to reducing the plastic piling up in landfills.

Comparing Feeding Methods for Plastic Recycling Equipment: Which One Suits Your Needs?

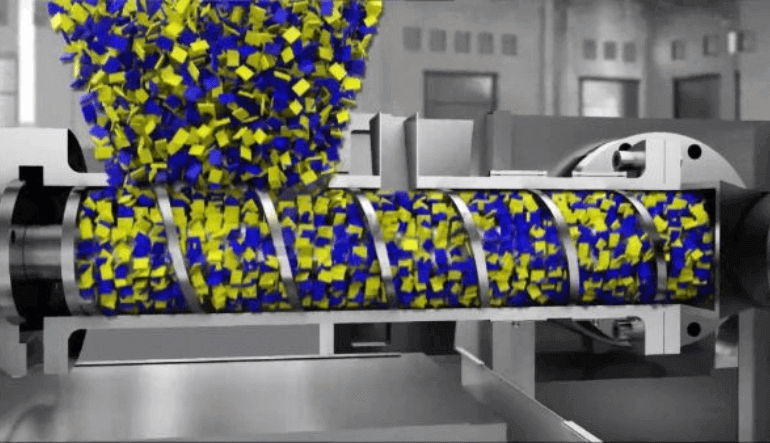

In the realm of plastic recycling, the way materials are fed into recycling equipment plays a pivotal role in determining overall efficiency and output. Whether handling thin films, bulky plastic waste, or powders, selecting the appropriate feeding method is essential for optimizing machine performance and maintaining consistent production. This article delves into the primary feeding methods used in plastic recycling equipment, highlighting their unique features and ideal applications.

POLYSTAR PP Raffia Recycling: An Eco-Friendly and Cost-Effective Approach for Manufacturers

PP raffia is a strong, durable, and cost-effective plastic widely used across various industries. However, improper disposal can lead to environmental harm. Fortunately, PP raffia is recyclable, offering manufacturers a sustainable solution to minimize their environmental impact while also benefiting economically.

Path to a Greener Tomorrow── CHYI YANG's CFV Solutions of Precision and Sustainability

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.

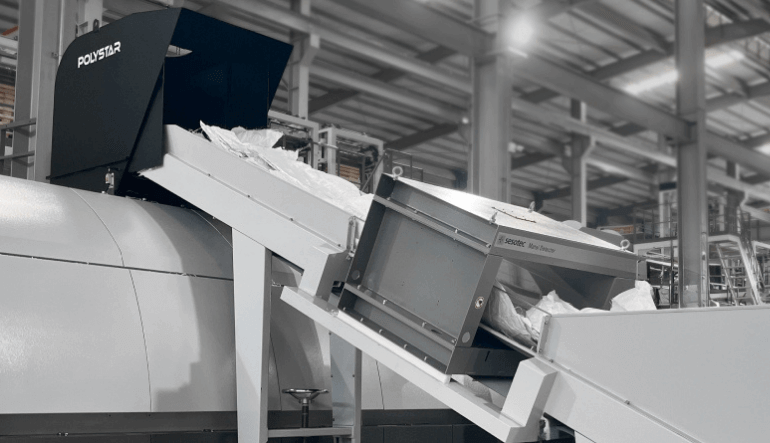

5 Advantages of POLYSTAR for Your Plastic Recycling and Blown Film Businesses

As a leading manufacturer in the plastic industry, more than 4950 POLYSTAR plastic recycling machines and blown film extruders are operating in 110 countries today. This is a result of our satisfied customers, who have experienced the advantages of using POLYSTAR machines for their businesses. Here we have listed 5 of those advantages that are most pointed out based on our customers' feedback.

Quality and Consistent Output with POLYSTAR Recycling Machines

Recyclates with proper pre-works and a recycling process with careful inspections will bring you high-quality plastic pellets which meet the market standards. POLYSTAR aims to help you identify any crucial missing elements in your plastic recycling process and provide suggestions to improve your recycling business.

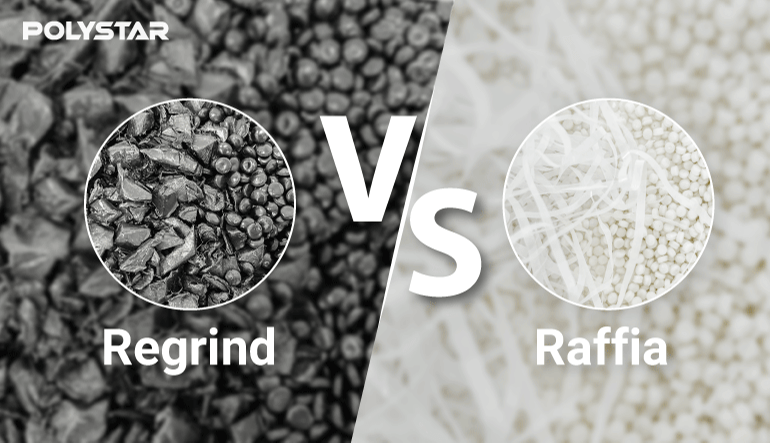

Choosing the Right Recycling Machine: Hard Plastic Regrind VS. PP Raffia/Woven Recycling

There are plenty of plastic material types that we use in daily life as well as in many different industries. In addition to different polymer types of them, these plastic materials also come in different shapes, sizes, textures, and levels of stiffness. These are the main points that plastic recycling machines should specialize to process certain types of plastics more efficiently while still capable to process various types of other plastic materials.

What is Post-Consumer Plastic Recycling? - Advantages and Solutions

Plastic is one of the most widely used materials worldwide, found in everything from food packaging to car parts. As a result, the amount of plastic waste produced is enormous, creating an environmental problem. This is where mechanical recycling has become a popular solution among plastic producers and recyclers.

Benefits of Recycling Plastic Film and Bag Production Wastes In-house

Due to the large size of productions of 15 years old fast-growing bag manufacturer for many different companies, the scraps generated from plastic flexible packages, patch and soft handle bags, punched-out handle bags, courier bags, exam bags, gift packages, shrink films and document pouches were considered as high. The bag producer needed to work with several professional recyclers to reprocess them.

Why to Use Recycled Plastic Pellets for Injection Molding instead of Regrinds?

Using recycled plastic pellets for injection molding brings several benefits to businesses as well as to the environment. These can be listed as reducing waste, conserving resources, saving material costs, improving sustainability, and creating positive public relations. Recycling injection molding manufacturing wastes is one of the fastest ways of generating recycled plastic for injection molding. On the other hand, using recycled plastics in injection molding in pellets form is also found superior to regrind form by many injection molding manufacturers.