近期更新 立即订阅

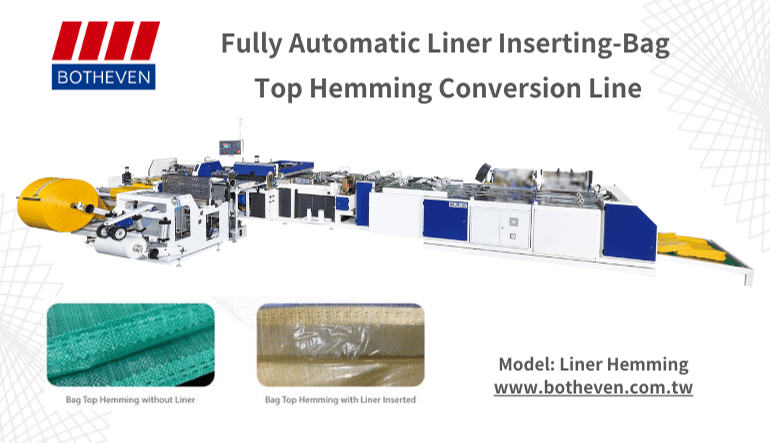

BOTHEVEN: CONVERTING INTO PERFECTION, SOLUTION FOR BAG MOUTH HEMMING

As we are gradually recovering from the pandemic, Botheven never stop developing new solutions for PP woven bag, we proudly announce new “Fully Automatic Liner Inserting-Bag Top Hemming Conversion Line” (Model: Liner Hemming), an all in one solution from liner inserting to bag top hemming, a truly automation for bag mouth processing.

翔音:模内贴标签

模内贴标签是近十年来较为先进的产品贴标方式,它适用于须大量自动化生产的产品。在射出机或吹瓶机加装供标系统即可使卷标与产品融合一并成型,无须为了贴标而进行二次加工,不仅缩短制程也能增加产能。

Customized with High Performance. Your best partner for Bio TPU , ETPU , LFRT and ABS | GRECO

ISOTHANE TPU resins are high quality environmental friendly materials and available in a wide range of hardness in polyester and polyether-based formulations. ISOTHANE exhibit the valuable characteristics of flexible rubber and rigid plastics and their wide spectrum of mechanical properties can meet customers’ demands in extensive applications. ISOTHANE TPU portfolio includes non-plasticizer soft grades, high transparency grades, hot melt grades, breathable film grades, medical/biocompatible grades, engineering grade, low compression grades, bio-renewable grades (Between 25~60% Bio-based), flame retardant grades, calendaring grade and TPU adhesion grades and special compounds like TPU with 40%, 50%, 60% Long Fiber Reinforced Compounding Materials (TPU LFRTs).

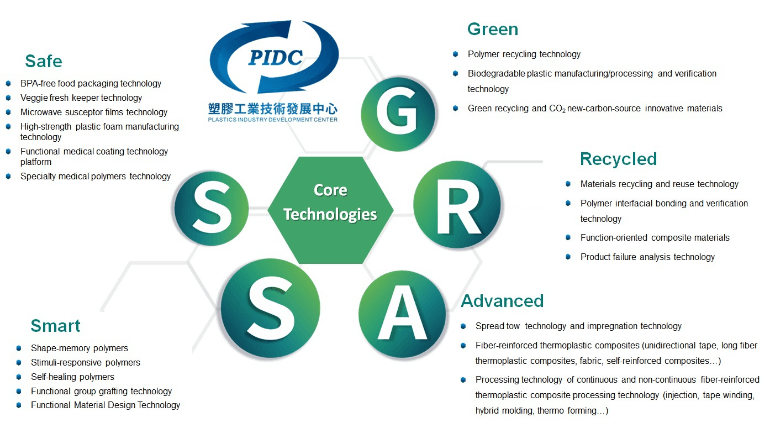

Plastics Innovation Towards ESG Sustainability

In response to the global trend of sustainable development and net-zero emissions, the innovation in the plastics industry is closely tied to the three dimensions of ESG (Environmental, Social, and Governance) sustainability. This has become a focal point of global industry innovation opportunities, and companies that can balance ESG sustainability while pursuing economic growth are now crucial.

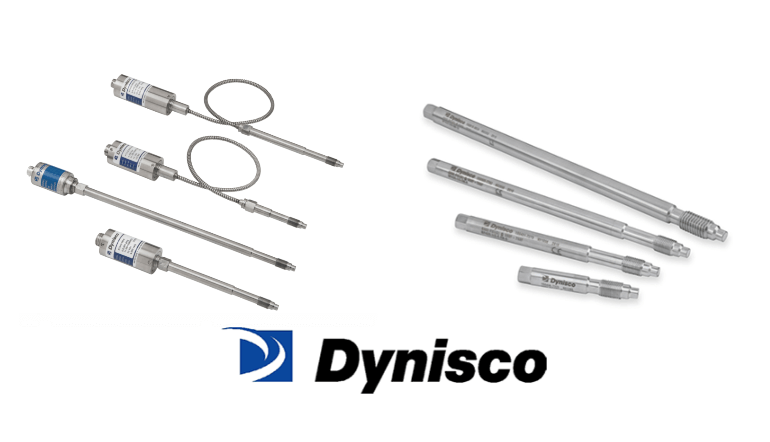

BRINGING THE BEST EXTRUSION SENSORS TO TAIWAN | MITSUDELL

For Industrial machinery one main component no matter what the pressure requirement is, whether it’s for safety reasons or extrusion optimization. The main player in this industry is Dynisco, the most recognized in the industry, thanks to their smart solutions and high-quality standards.

2023 Chinaplas KEENPRO all-in-one planning | KEENPRO

KEENPRO INDUSTRY CORP. focus on energy saving and power saving and intelligent PET bottle blowing. Whole plant equipment, providing all-in-one planning for the entire production line, assisting in material conversion, flexible and customized development to meet customer needs.

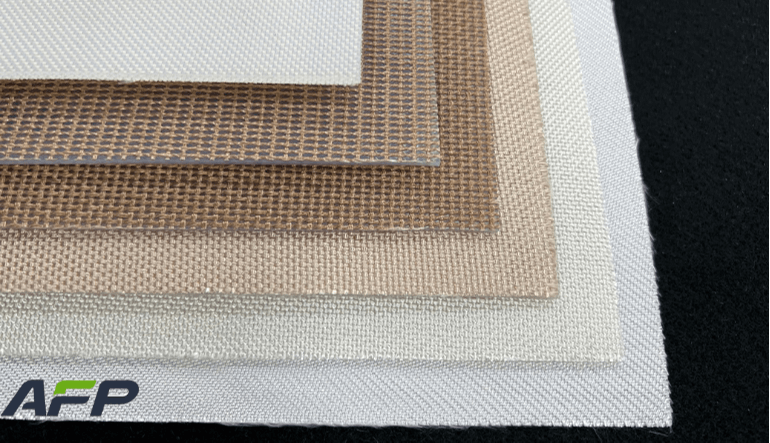

What is PnP? | AFP

PnP, which stands for PLS + AFPs + AFP, is a quality assurance system that can also be understood as a resource sharing platform, providing the practical effect of "Protect Inside & Protect Outside".

晏邦电机-配色混料机高精准完美呈现设计者巧思

后疫情时代来临,虽然政府不再强制戴口罩,但家中如果没有准备口罩、酒精…等防疫物资,你安心吗?

The Leader in Blown Molding Machinery Industry | CHEN WAY

When International customers think about Blown Molding Machinery, one of the main concerns that come to their minds is quality and reliability, Taiwanese companies are well known to offer both plus good competitive prices. Chen Way Machinery is a company that must be considered when we talk about this kind of machine. They have 30 years of vast experience that has achieved outstanding success within the industry. Also, they have been focused on their Research and Development constantly, in order to always be in the vanguard and offer the latest trends in the industry to its customers.

Empowering the Blown Film Industry with Sustainable Solutions at Expo Plasticos 2023

Genius Machinery, a leading manufacturer of recycling machinery, will be participating in Expo Plasticos 2023 in March. Our aim is to display the newest innovations in the plastic recycling industry to all attendees. An essential product we will be featuring at the expo is the air cooling pelletizing machine. This machine boasts an air cooling hot face cutting system that provides an efficient solution for recycling plastic film or bag scraps. We're excited to present our cutting-edge technology to attendees and demonstrate the ways in which our machines can help businesses of all sizes from the blown film industry optimize their recycling operations.

NAN YUN: Professional in Design and Manufacture of Large Screws and Barrels

Established in 1993, NAN YUN Industrial Co., Ltd. specializes in the design and manufacture of full series of screws and barrels. NAN YUN has an engineer's design team with outstanding theoretical background and practical experience, hence they are able to design high-output and high-performance products as required by customers, and also use Computer Numerical Control (CNC) equipment to manufacture products that satisfy customers.

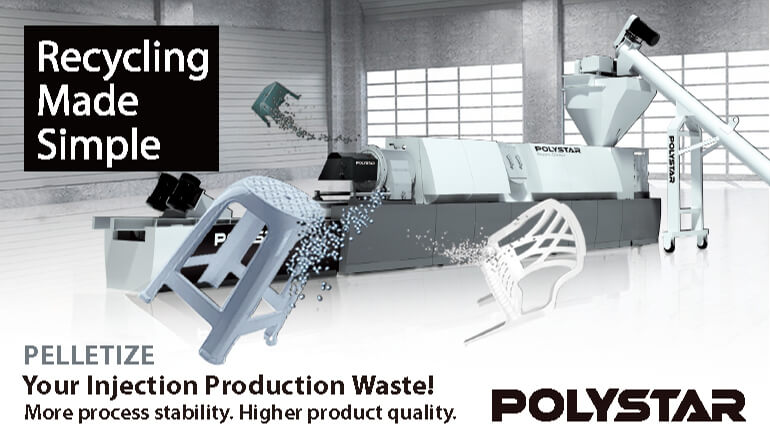

Why to Use Recycled Plastic Pellets for Injection Molding instead of Regrinds?

Using recycled plastic pellets for injection molding brings several benefits to businesses as well as to the environment. These can be listed as reducing waste, conserving resources, saving material costs, improving sustainability, and creating positive public relations. Recycling injection molding manufacturing wastes is one of the fastest ways of generating recycled plastic for injection molding. On the other hand, using recycled plastics in injection molding in pellets form is also found superior to regrind form by many injection molding manufacturers.