近期更新 立即订阅

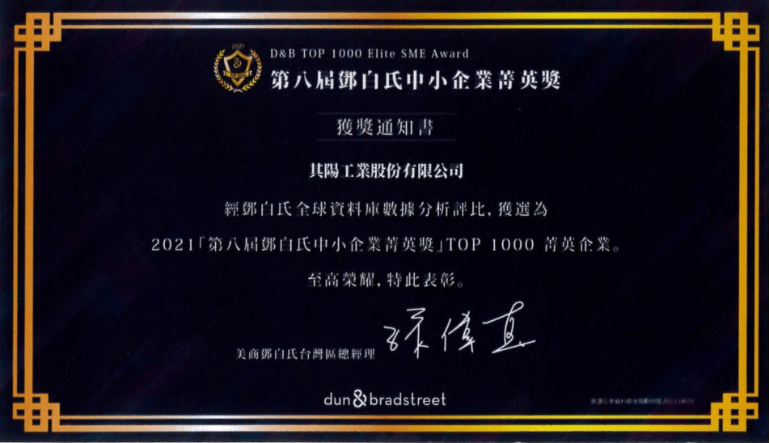

Congratulations to CHYI YANG for Being Awarded the 8th Dun & Bradstreet SME Elite Award

According to the data analysis and evaluation of Dun & Bradstreet's global database, it was selected as the Top 1000 Elite Enterprises in 2021 the 8th Dun & Bradstreet SME Elite Award.

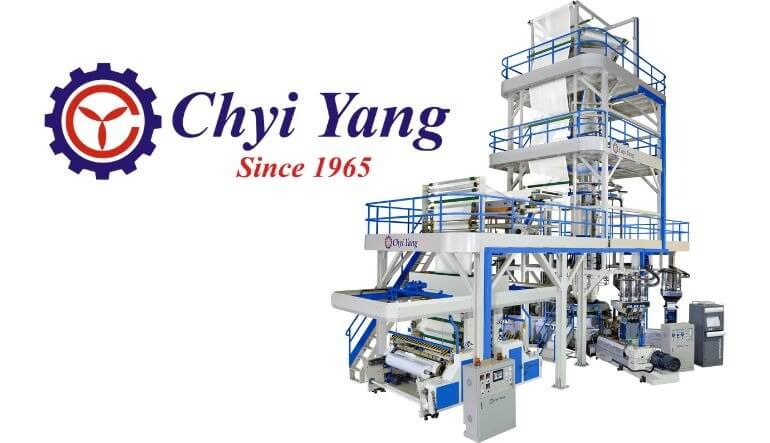

Super Provider of Essential Blown Film Line for the "Unmanned Factory"

Global manufacturing has been struggling in recent years to address the labour shortage. The wave of automation has arrived quickly due to the significant impact of global pandemic, wars, and other "black swan" effects - and the market's industrial upgrade is about to occur. Right now, it appears that there is a major global supplier of film-blowing technology who has been quietly offering automated equipment solutions for years, aiding in the establishment of "unmanned factories," and strongly supporting these film manufacturers to successfully pass the "post-pandemic era." Chyi Yang Industrial Co. is the super provider of this key blown film line solution.

The Multilayer Film Boom: Why Companies are Investing

International Plastics News for Asia | Chi-Chuan Cheng The Multi-Layer Co-Extrusion Film Blowing Machine plays a vital role in modern plastic production with its benefits of high efficiency, automation, precision, and energy efficiency. It finds applications not only in food, building materials, and agriculture but also in fields like medicine, chemical, and electronics.

Quality Triumphs Cost ── Lessons from a Leading Vietnamese Industrial Player CHYI YANG's Customer-Centric Approach

International Plastics News for Asia | Chi-Chuan Cheng The crucial consideration for manufacturers is whether to cut costs or enhance value. There is a well-established plastic film producer located in Hanoi, Vietnam, which a few years ago purchased blown film machines from the renowned quality-driven company, Chyi Yang. However, due to price considerations, the factory later shifted to purchasing low-cost multilayer blown film machines manufactured in China, temporarily expanding its production capacity. Despite momentarily stepping back from the price competition, Chyi Yang remains steadfast in its commitment to quality-driven development, continuously innovating and advancing with the introduction of various styles of 5-layer / 7-layer co-extrusion blown film machines.

Path to a Greener Tomorrow── CHYI YANG's CFV Solutions of Precision and Sustainability

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.