近期更新 立即订阅

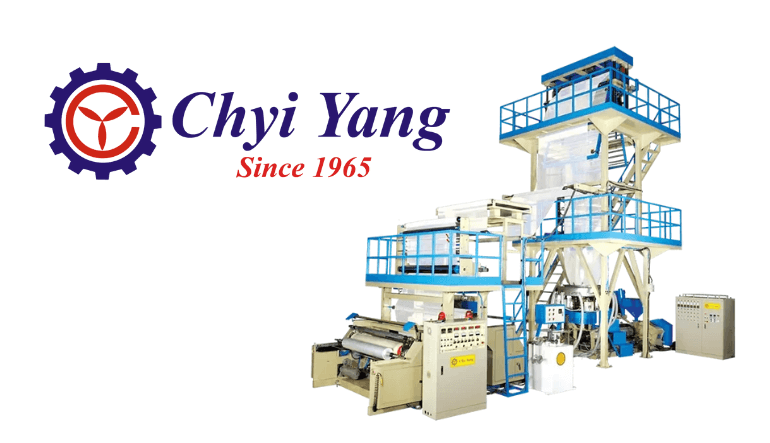

Outstanding Quality Blown Film Machine Gets a Vietnam-listed Company's Favor

One of the listed companies in Vietnam purchased three sets of blown film machine from Chyi Yang 20 years ago. Afterward, in response to enlarged scope of the company and to reduce the cost, they turned to import equipment from China with lower price. However, the quality of film produced from China machine did not meet Japanese customer’s standard and up to 20 freight containers of products were returned in one transaction.

Meet Your Needs for Stable Thickness, High Productivity & Multilayer Quality with CHYI YANG Blown Film Machine

The global ESG trend is forming, and corporate sustainability will become a "standard" for businesses. As the European Union takes the lead in announcing the 2030 carbon reduction target, countries follow suit, and the plastic film industry is also contributing to the trend of sustainable development.

Do You Know the Invisible Champion Who Can Assist You Enter into the Cling Film/Wrapping Film Market with Ease?

How do we make PE cling film that is non-toxic, breathable, and easy to tear and break? Ask Chyi Yang, the company that provides a complete plant solution that enables beginning manufacturers to enter the PE cling film/wrapping film market with just one machine, allowing them to cope with the unpredictable market environment easily.

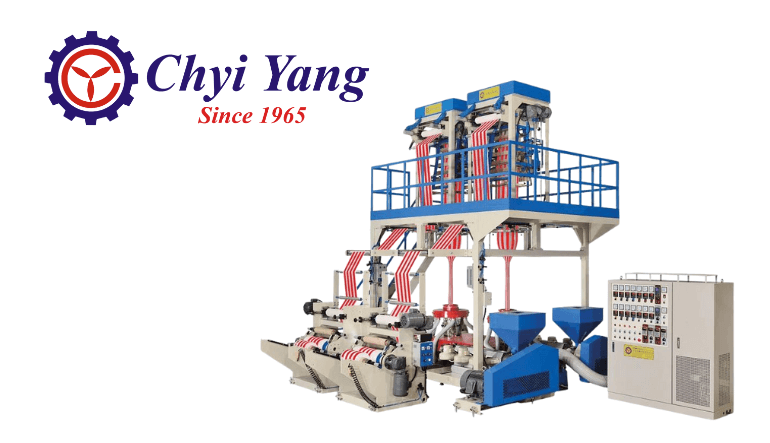

Super High Speed HDPE Capacity Blown Film Machine in Less Space

Chyi Yang showed one set “Two Stripes & Two dies Co-Extrusion Blown Film Machine” in Andina-Pack 2015 Colombia exhibition. This machine is equipped with two dies & two extruders to produce two stripes T-shirt bags for market using. The two 45mm extruders provide two dies to have 2-line film rolls at one time. Forced feeding extruders offer you bigger capacity, the max. capacity is 140kgs/hr. for 550mm film width at 20micron film thickness. You can get max. 70kgs/hr. from each winder, and max. 140kgs/hr. from two winders.

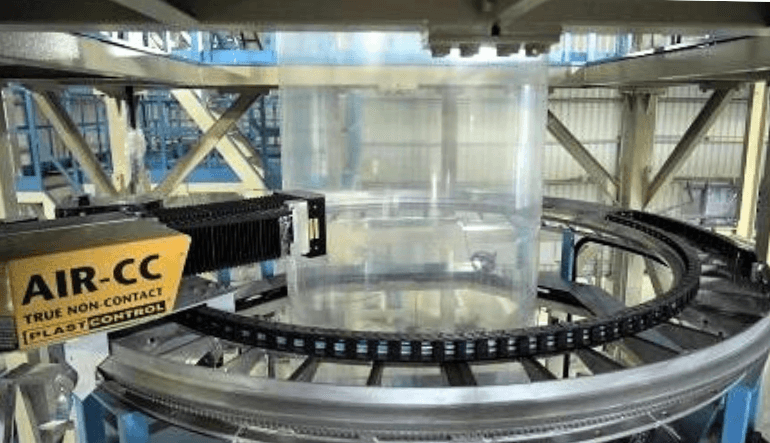

How Can High Quality be Produced Consistently out of Complex Formulations?

The blown film market is evolving in an increasingly fast pace to meet the highly diversified, large-volume and variable material requirements of industries and emerging applications. Bag manufacturers and packaging material producers must use blown film machines with hardness, corrosion resistance, and durability to achieve consistently high yields while maintaining quality. More important goal is meeting the demands in film processing with complex characteristics such as those for agricultural films, cover films, laminated films, grain and dry food packaging, medical packaging and other critical packaging.