KW-B2 BLISTER PACKING MACHINE

产品分类 : 胶囊/片剂包装机

KW-B2 blister packing m/c applies the latest technology contribute to a low cost, low packing material consumption.....

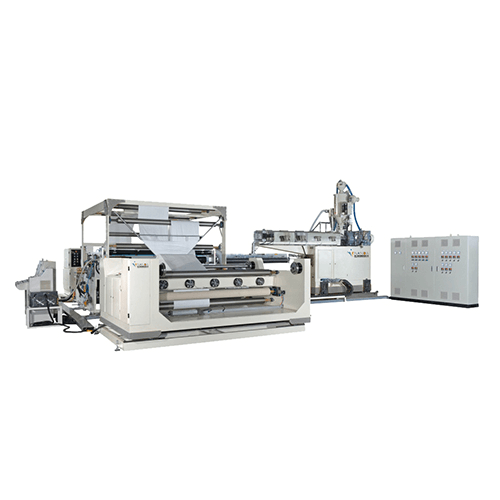

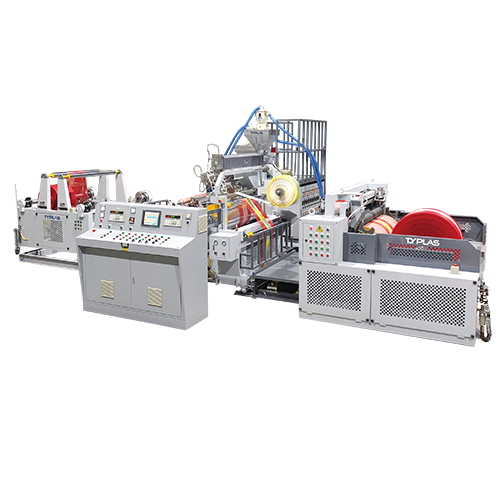

SL-The lightweight coating and laminator

产品分类 : 工业复合机

SL (The lightweight coating and laminator) The Solventless laminator provides an answer for the growing environmental concerns and protection measures. It also eliminates the possibility of solvent migration, making it preferred by food processing companies. If you are looking for environmentally friendly lightweight solution, this is the press for you to customize. KYMC

胶板押出机- HC-100PET

PET具有高透明度、高亮度、高强度、轫性强的特性,加上为环保的材料,现已取代PVC产品,成为市场主流。本机具有精密控制且省电,所制成的胶片,厚度均匀,透明度高。

MPT 微电脑温控制器系列(高阶型)

产品分类 : 控制设备

同时具有MPR型及MPE型各项特点。 具有单片面板同时多段温度控制,帮助客户节省体积与成本。 通过通讯阜,可人机接口设定流程,档案储存。 具有检测Module漏电、FUSE开路故障警报。 具多种保护功能设计,能避免各种人为疏失所造成感温线、加热器及温控面板损坏。

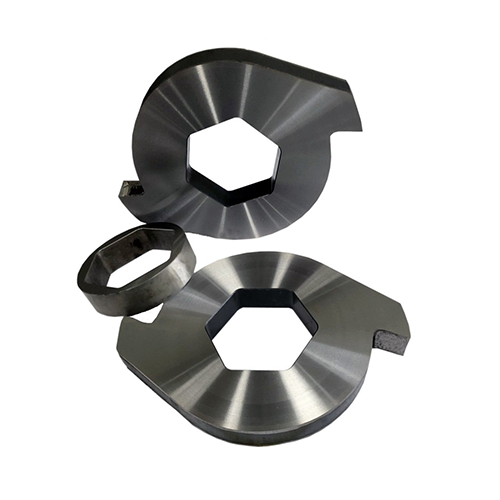

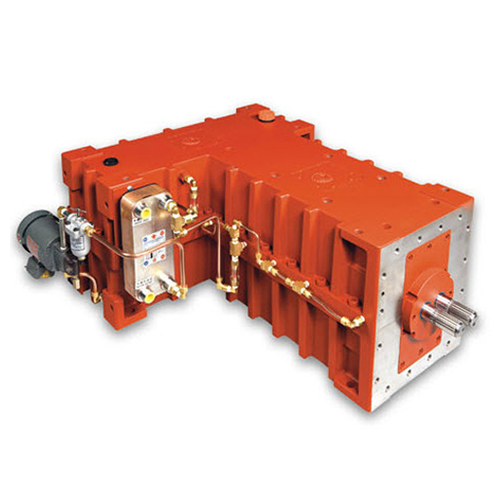

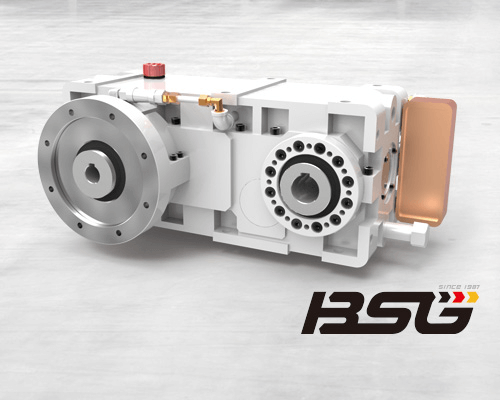

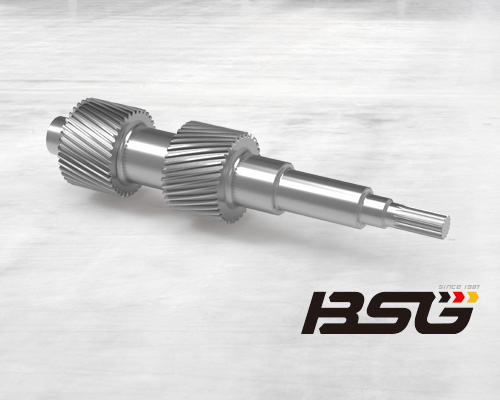

Direct Drive Gearbox

产品分类 : 齿轮

全电式连续式中空成型机

产品分类 : 电动中空成型机

Servo Motor: Clamping Unit/Carrier Moving/Blow Pin/Parison Control Application: For Foods And Medical Or Special Application

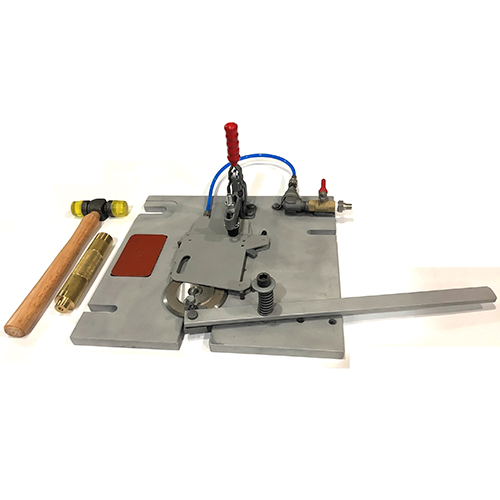

三合一刀片拆装装置T1

产品分类 : 工业用刀具

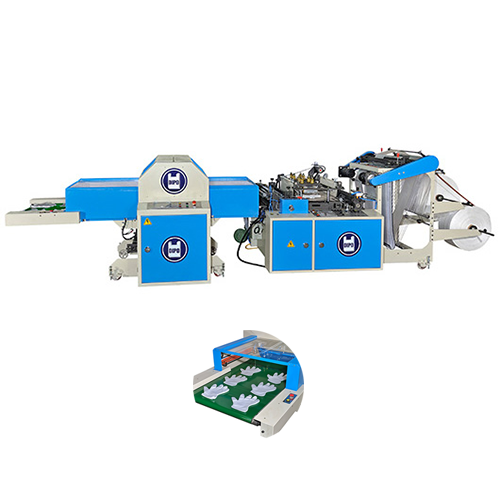

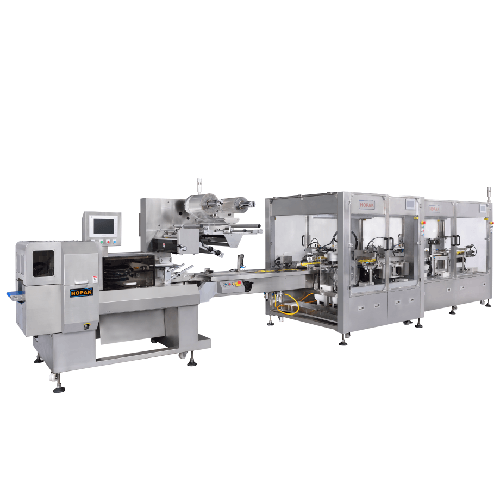

Group packaging line with vision detection ,robotic disc arm and distributary station

产品分类 : 干式包装机

Group packaging line with vision detection ,robotic disc arm and distributary station

CNC伺服机械手-W7 系列

产品分类 : 工业机器人

· 通讯控制 · 多语言编程 · 每轴皆可于作业中编程 · 可自由编程安全空间 · 主子程序可同时执行 · 内存:最高可存至五百组程序 · 标准E67,E12和SPI接口 · 多层密码设定 · 模拟式数字感应监测真空信号 · 人性化编程控制,大幅节省操作训练时间

PET瓶拉吹机系列PK-20PSB

产品分类 : 自动吹瓶机

Onion Leno Bag Laminating Machine-TY-LMLB Series

产品分类 : 淋膜机

The main functions of the LMLB series can be made of two kinds of film at the same time. First is onion mesh cloth and printing leno through the lamination for bonding in the middle. Second is to laminate the film about 70-100 mm wide at the side, and this side film will do hole-punching process and used as auto filling and packing.

多轴自动贴膜机AFC-700LE

产品分类 : 切割机

Patented Bonding Mechanism: In achieving higher bonding accuracy and without air bubbles. Fully Automatic Tension Control System: The tension of materials for each axle is controlled in an automatic way. Servo Transmission Control: Dual-Axle servomotor is used to achieve synchronized alignment control. Diversified Size Option: The parameter fine-tuning can be executed according to the characteristics of different materials. High Clean Bonding Environment: Which meet high-cleanliness bonding space requirements in providing higher Y-Rate. Unique Material Handling Techniques: Which is designed according to the characteristics of optical film to avoid scratching the material.

DG-EP 系列 伺服马达驱动射出成型机

产品分类 : 自动注塑机

•于低速范围有极优秀之安定控制 •长时间高压的射出保压性能 •30ms高应答射出 •几乎与电动式射出机一样的电力消耗 •射出速度及压力闭回路控制,高度之成型安定性 •关模机构使用免润滑轴套+黄油润滑系统

PP/PS Rigid Sheet Recycle Machine

产品分类 : 废塑料回收机

To have PP/PS Rigid sheet wastage be recycled which can be used in industrial field and make it more friendly in this environment.

INSERT INJECTION MOLD

产品分类 : 注塑模具

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

2RT开模轮胎胶囊专用橡胶后射式成型机

产品分类 : 橡胶注射成型机

2RT超越了传统的顶部开模,可用于双模或三模,并具有开模的设计并在两者之间推出模具。可以通过软件调整开模,并分别打开,分开推开模具,连续打开和连续推开模具。

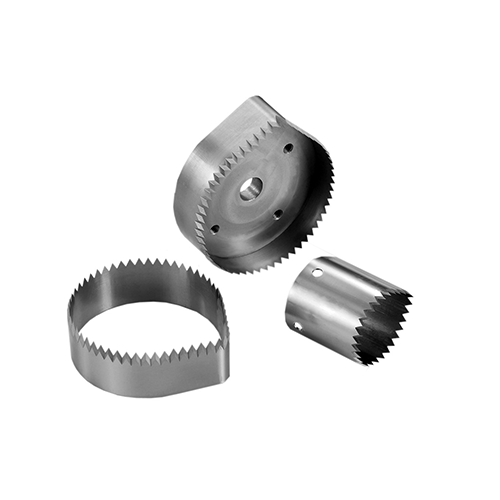

Cylinder Gear

产品分类 : 齿轮