PP 射出级/ 黑色

产品分类 : 聚丙烯树脂

THS 850/950

产品分类 : 工业机器人

•真空夹具电路。 •自动模式微修改。 •自动堆垛/码垛。 •从模具的型芯/型腔侧取出零件。 •拒绝零件/报警/操作历史。 •站在模具上,等待外面的模具。 •错误的计数/分解历史/操作记录。

LDPE超高速吹膜机

产品分类 : 吹膜挤出机

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

Automatic High Speed Case Packer - SFA-SD30

产品分类 : 真空包装机

Human-Computer Interaction Design. Fully Wrap Around carton packaging and Tray Packing Combination Operation. Parameters can be set and modified on the screen. Wheel handle for minimization of changeover times, in order to quiktly switch from a production to another one. All moveable parts and Electrical wiring are cover up for safety issue. Machine operation with less noise. Missing/Fallen loose product detection before the tray/case forming unit. Glue spraying distance is control by encoder, ensuring consistent glue spraying length on each carton and permit adjustment and memorizing at any time.

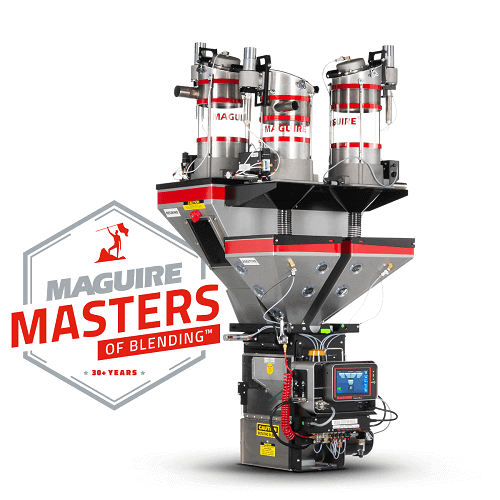

WSB Gravimetric Blenders

产品分类 : 计量和测量设备

WSB Gravimetric Blenders The Maguire blender is the most popular and reliable gravimetric blender worldwide. 10 blender series with over 120 models Close to 60,000 Maguire Gravimetric Blenders running worldwide More standard models than any other producer

HA series - 950SW

产品分类 : 工业机器人

INSERT INJECTION MOLD

产品分类 : 注塑模具

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

尼龙 6 工程塑胶 - NA1100G45

产品分类 : PA(聚酰胺)/尼龙

Glass fiber 45% reinforced, high flow. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

尼龙 66 工程塑料 - NB7200G33

产品分类 : PA(聚酰胺)/尼龙

33%玻璃纤维增强 (黑色-高流动性) 应用说明:手工具、电动工具、园艺工具用,汽车、机车、脚踏车零组件用,运动器材零组件用,电子、电器外壳及零组件用,O.A.办公室零组件用,水资材用,医疗复健器材。

4RT开模骨架油封专用橡矽胶真空热压成型机VOCC-D3W

产品分类 : 制鞋机

机体设计机体采用钢板组合,适合各种油封生产。出入模设计出入模框有装上耐磨片,可长期进出使用,定位准确。真空室设计真空闸门开关顺畅、安静、密封性好,真空度高。油箱设计具六种开模之动作模式选择,绝对能满足使用者的需求。取成品设计有上、下顶出成品设计。操作简单,生产速度特别快。维修与保养所有定位近接开关,都装在真空室外面。维修、保养方便又耐用。油路设计采各别油路系统设计。两轴可同时操作。

全自动补丁手柄/循环处理/聚抽奖处理/模切处理制袋机SPH系列

产品分类 : 塑料制袋机

●型号:SPH-321S●速度(循环/分钟):30-80●宽度(mm):250-600●长度(mm):250-600生产各种手柄袋,模切手柄袋,拉带袋和贴片手柄袋。

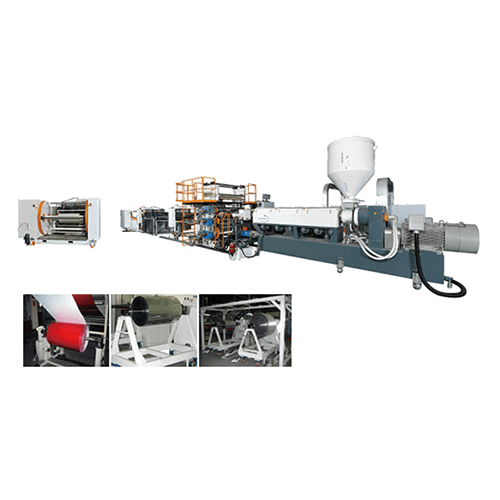

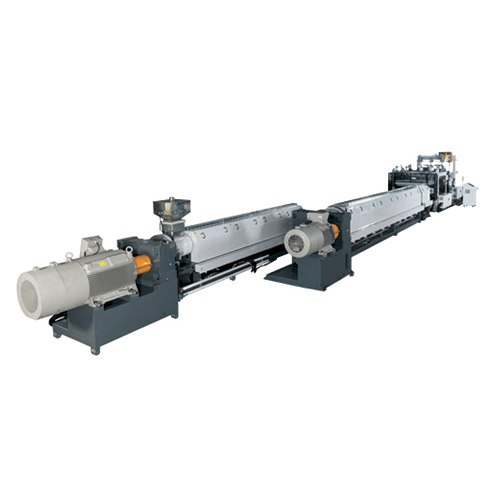

XPS 发泡隔热板押出机系列

产品分类 : 发泡挤出机

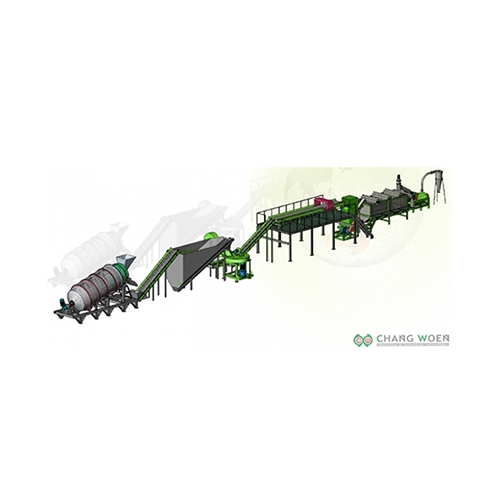

PET瓶回收处理线A级

产品分类 : 瓶类回收产线

高精度卷对卷自动送料裁断机TRC-350SP

产品分类 : 发泡机械

装轴同步送料机构: 双轴同步送料提高了产出速度及良率。优越且安定的下死点精度: 采用了矗霖特有之专利下死点机构,重复定位精度+-0.005mm。高精度深度调整机构: 采用高精度机构,微调精度可达0.01mm(0.001mm为选配)。高效率增压回路: 较传统回路减少了30%以上之电力消耗。光学材料对应: 可依照材料之特性做专用之搬送系统。独特的材料搬送机构: 高稳定性之伺服控制系统,不会污染及刮伤材料。自动润滑机能: 全机采用自动润滑机构,减少日常保养的工作。废料收卷机构: 裁断加工后之废料自动收卷,节省空间,提高作业性。

高速精密立式射出成型机-YQ系列

产品分类 : 立式注塑机

• Vertical four-pillar vertical clamping, with vertical injection. • The square pillar design comes with large mold size. The space within the column allows customers to install devices of automatic embedding and removing products. This allows automation for the whole machinery. • Big L / D ratio of screw, plasticizing evenly, suitable for injection molding of engineering plastics. • High standard computer control system with high precision injection pressure and high response injection speed. The quality is more stable for high-precision embedded injection molding products. • 1S single sliding: After mold opening, the lower mold will automatically slip in front of the operator for facilitating embedded molding operation. • 2S double sliding (Alternating double sliding): One mold for injection molding, another mold for taking out and putting on embedded parts operation. • 2SL double sliding (90°Alternating double sliding): One operator can operate independently. One mold for injection molding, another mold for material taking and putting on embedded parts. The two slidings are intersecting at 90 degrees, which can lower the production cost, and enhance the performance. • Able to combine automation and the high-speed injection can effectively enhance the production capacity. • A variety of circuit design (half closed servo hydraulic or high speed injection) to meet the customer’s requirements.

VTOP 系列精密立式柱塞式射出机

产品分类 : 自动注塑机

● 专利模组化三合一可更换滑板设计,一机多用途● 可生产0.001-0.0001g精密射出产品● 专利IPIS可更换柱塞式射出系统,可模组化更换射出单元● 专利设计辅助进料系统,贮料跟卧式机一样精准● 柱塞式射出可大幅节省浇道塑胶● 两板直压式四缸锁模机构● 专利辐射式力学范本耐用30年● 安全光栅及安全门双重防护●智慧程式控制系统让射出更容易● 相对同规格机型,机台高度最低● 符合人体工学的工作台高度● 电脑控温气冷式油冷却系统● 精密节能油电伺服系统

PP 工程塑胶 - PP1200G40

产品分类 : 聚丙烯树脂

40%玻璃纤维增强(本色) 应用说明:风扇叶片,手工具,园艺工具用,运动器材,家电产品零件,医疗复健器材,O.A.办公室零组件用。