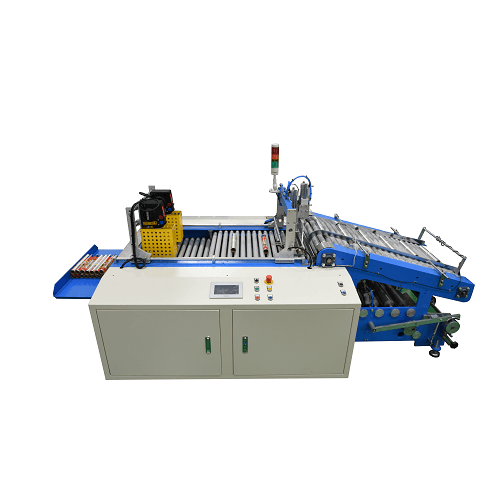

高精度卷对卷自动送料裁断机TRC-350CP

产品分类 : 发泡机械

特殊送料机构: 针对不同特性之材料所设计,使软性材料自动化加工变成可能。优越且安定的下死点精度: 采用了矗霖特有之专利下死点机构,重复定位精度+-0.005mm。高精度深度调整机构: 采用高精度机构,微调精度可达0.01mm(0.001mm为选配)。高效率增压回路: 较传统回路减少了30%以上之电力消耗。多层材料对应: 可一次加工四卷以上材料,生产效率成倍数成长。独特的张力传送结构: 有效控制材料的搬送偏移公差,提高产出良率。自动润滑机能: 全机采用了自动润滑机构,减少了日常保养的工作。废料收卷机构: 裁断加工后之废料自动收卷,节省空间,提高作业性。

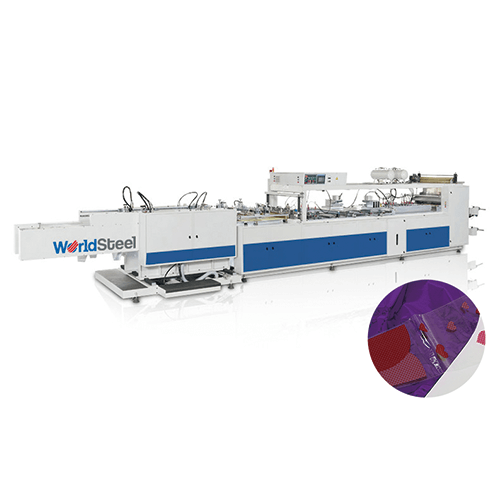

Secondary Packaging - Cartoning - CSC-50A

产品分类 : 装盒机

The cartoning equipment applies the vertical automatic production operation. The equipment is suitable for more types with medium capacity products

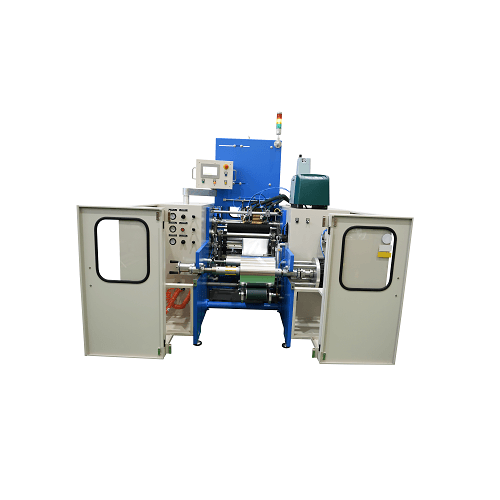

AUTOMATIC SHRINK FILM PACKAGING MACHINE (TPG 50)

产品分类 : 分切机和复卷机

Model TPG50, the automatic shrink film packaging machine. A special design for wrap roll products. It can be connected to the back side of rewinding machine as an automatic production line. You can not only make your product refined and protected, but also arrange manpower more effectively. TPG50 is carried 3 conveyors as 3 work areas. It uses conveyors to deliver products to the processing area. You can choose automatic feeding of the material,or feed by detected sensor. As shrinkable films, BOPP, PVC and PE can be used on TPG50. The length of over wrapping film can be set manually or detected by the mark sensor. For packing decoration, you can use printed film; or, equip with a label paper device. The device will insert a piece of label before shrinking. The label will be wrapped inside the film, makes your product eye-catching. The last step, electrostatic device and thermal-wind will perfectly pack your products! Welcome to consult machine with us, we will at your service.

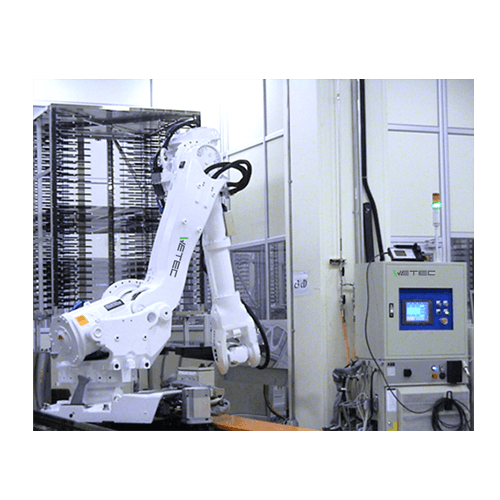

TFT-LCD基板移载系统整合

产品分类 : 工业机器人

· 玻璃基板移载系统 · 真空镀膜Loading Unloading · CF Packing Unpacking · CELL段自动化移载 · 模块段制程自动化 · CF检测移载自动化 · CIM软件整合

RAPID PROTOTYPING

产品分类 : 热流道系统

With the advent of 3D printing, rapid prototyping can now be done quickly and affordably. YOMURA TECHNOLOGIES is equipped with a high end, Digital Light Processor 3D printer built by Carima, a South Korean company with over 30 years of optical manufacturing experience. Unlike Fused Deposition Modeling (FDM) 3D printing which heats a plastic filament then squeezes it through a nozzle to print one layer at a time, DLP uses a special light wave to activate a chemical reaction in a photopolymer resin which then cures into solid 3D object. DLP objects are smoother, more detailed and almost seamless, ideal for professional quality prototypes. 3D PRINTER SPECS Max Build speed: 30mm/hr Resolution: 1920 x 1080 Size: 200 x 112 x 200mm 245 DPI High-end DLP (Digital Light Processing) 12 micron engine enables a very fine prototype Very minimal material waste MATERIALS Acryl: Easy post processing and coloring ABS-like: Semi ABS durability Epoxy: Great durability Rubber-like: Elastic material Lost-Wax: Metal Casting

塑胶采光浪板- L1

聚碳酸酯角浪板是一个具有优异的耐冲击性,透明性和高透光度的高聚合物。其优良的机械性能、热性能和电气性能使其在建筑施工、景观、农牧业、DIY项目或旨在提高采光日照的任何建案中,皆为优良的材料。

胶板押出机- HC-100PET

PET具有高透明度、高亮度、高强度、轫性强的特性,加上为环保的材料,现已取代PVC产品,成为市场主流。本机具有精密控制且省电,所制成的胶片,厚度均匀,透明度高。

一段两工位式射出延伸吹瓶机- ISB 系列

产品分类 : 注塑中空成型机

本机种采用最先进『 一步法射出延伸吹瓶』成形工艺,只需单机即可达到高质量产出效率,比较两步法PET成型机,本机所占优势包括:节约能源--低耗电率、节省设备占用空间、单机采购可减少开发试模风险、开模成本低--迎合市场产品多样化需求、专适于小容量精致容器,因此可提升客户接单之竞争力。

SIX SHAFTS TYPE AUTOMATIC ALUMINUM FOIL / CLING FILM REWINDER (AH-6S)

产品分类 : 分切机和复卷机

AH-6S, the six shaft type automatic rewinding machine. It's designed for rewind aluminum, PE and PVC cling film. The feeding press roller is carried with precise pressure manometer and regulating valve. Movements include automatic feeding material, automatic cutting and unloading the finished product. This model has automatic length correcting function. It can correct the margin of product length anytime. There are 2 type of mother roll width for AH-6S: from 250-450 mm, and from 300-500 mm. The product length is from 3-250 meters, the finished paper core's I.D. can be appointed within 25-38 mm. Users can choose to equip label sticker device and hot melt glue device with machine. They will make product more perfect. Stably fix the material on the paper core, neatly produce product with smooth edge. Machine brings you a huge benefit in the way you need. Welcome to consult machine with us. We will at your service.

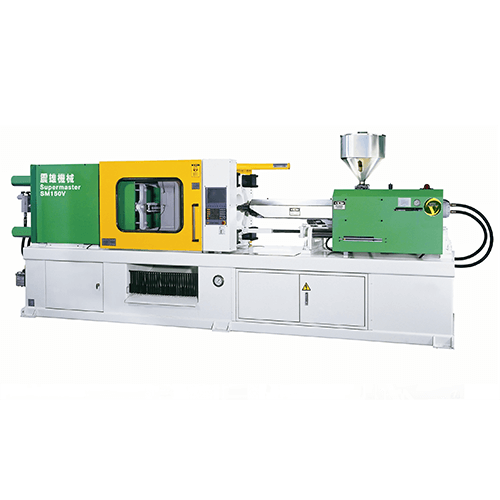

曲肘式伺服节能射出成型机 (SMV 系列)

产品分类 : 卧式注塑机

• 双油缸射出的设计,射胶传动距离短节省空间。 • 螺杆、料管及易磨损机件经离子氮化处理,寿命特长。 • 多段射胶速度及压力控制,适合各种精密成型调整容易。 • 钢质衬套,渗碳处理后硬度高达HV800耐压耐磨,特久耐用。 • 曲肘自动给油润滑系统,附无油警报,可确保曲肘润滑性,保养容易。 • 油压多次顶出,配合机械手取出装置,达至全自动化生产阶段。 • 特快锁模系统,采用油压差动回路,提高速度达60%以上,缩短周期,节省能源。 • 低压锁模装置,保护模具。