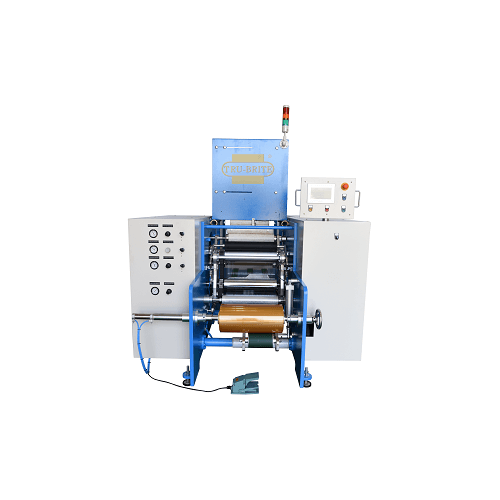

THREE-SHAFTS TYPE AUTOMATIC CLING FILM REWINDER (ADJUSTMENT) (TB-CW-3S)

产品分类 : 分切机和复卷机

TB-CW-3S, three shaft type automatic cling film rewinding machine. It's designed for PE & PVC cling film, suitable for rewind big paper core which the inner diameter is from 50-76 mm. The finished rolls outer diameter is up to 150 mm. Every shaft is carried catching and discharging units, automatic feeding, and automatic unloading. Automated length correcting makes every product accurate. TB-CW-3S uses the heating strip cutting system. It fits various materials quickly, cuts more precisely, makes users adjust machine more convenient. TB-CW-3S brings you better operation and higher efficiency. Welcome to consult machine with us. We will at your service.

上升-下降橡胶射出成型机

产品分类 : 橡胶注射成型机

产品特性射出量控制采高精密度光学尺设计,能准确的控制与计算射出量之大小。转射板设计具特殊的座进、座退功能,可使射嘴不死料。清料容易,品质稳定。安全设计备有高科技红外线安全电眼,并具有全自动警告系统及多重安全防护装置,可清楚掌握机台状况,确保安全。油路设计比压比流油路设计,稳定、安静、故障率低,两轴可同时操作。

高精度卷对卷自动送料裁断机TRC-350SP

产品分类 : 发泡机械

装轴同步送料机构: 双轴同步送料提高了产出速度及良率。优越且安定的下死点精度: 采用了矗霖特有之专利下死点机构,重复定位精度+-0.005mm。高精度深度调整机构: 采用高精度机构,微调精度可达0.01mm(0.001mm为选配)。高效率增压回路: 较传统回路减少了30%以上之电力消耗。光学材料对应: 可依照材料之特性做专用之搬送系统。独特的材料搬送机构: 高稳定性之伺服控制系统,不会污染及刮伤材料。自动润滑机能: 全机采用自动润滑机构,减少日常保养的工作。废料收卷机构: 裁断加工后之废料自动收卷,节省空间,提高作业性。

高速钢模裁断机HSP-12

产品分类 : 发泡机械

新型送料机构: 针对成型后材料高度不同设计了自动升降送料系统。优越且安定的下死点精度: 采用双轴同步机械结构,下死点稳定性高。高精度深度调整机构: 采用左右同步微调机构,微调精度可达0.01mm。参数储存功能: 可将设定后之相关参数命名并储存。成型机连线功能: 成型机做同步控制进行连线作业。自动润滑机能: 全机采用了自动润滑机构,减少了日常保养的工作。

WINDER

产品分类 : 分切机和复卷机

Winder is installed on the calender production line or on the end of production line that carries out exchange or rewinding various materials, in response to different winding requirement according to the products. Our winder adopt precise guidance and easy to operate. The speed is up to 200 m / min, the reel diameter is up to 1500mm, width is up to 6000mm. Some models are capable of reeling the upper side of films into the inner or outer roller. And after cutting the film into the desired specification, up to 3 rollers from the single spindle can be done. Processing with the drive motor and control system, the maximum tension precision at high-speed is guaranteed. We have a broad selection of winders for different product layout or custom. Automatic center winder (taping or Free taping type), automatic single roller surface winder, multi-roller surface winder; auxiliary equipment (trimming cutter and central cutting device, roll unwinding equipment and weighing unit, automatic roller puller), etc.

Skip Conveyor

产品分类 : 装载机和输送机

Skip Conveyor For Various Automation Production Line To Design Match, Between Machine To Carry Compound Process.

高精度小尺寸自动裁断生产线-APL-300

产品分类 : 发泡机械

●伺服裁断机构: 裁断主轴采用伺服马达控制,高效率,高精度。 ●自动送料机构: 采用高阶伺服控制,送料速度快,定位精准。 ●与多轴自动贴合机连线: 与RAL-400高精度多轴自动贴合机连线作同步加工。 ●与自动切片机连线: 与AC-300小尺寸切片机连线作切片加工。 ●二次加工对应: 可对应双站对位裁断加工。

高精度卷对卷自动送料裁断机TRC-350CP

产品分类 : 发泡机械

特殊送料机构: 针对不同特性之材料所设计,使软性材料自动化加工变成可能。优越且安定的下死点精度: 采用了矗霖特有之专利下死点机构,重复定位精度+-0.005mm。高精度深度调整机构: 采用高精度机构,微调精度可达0.01mm(0.001mm为选配)。高效率增压回路: 较传统回路减少了30%以上之电力消耗。多层材料对应: 可一次加工四卷以上材料,生产效率成倍数成长。独特的张力传送结构: 有效控制材料的搬送偏移公差,提高产出良率。自动润滑机能: 全机采用了自动润滑机构,减少了日常保养的工作。废料收卷机构: 裁断加工后之废料自动收卷,节省空间,提高作业性。