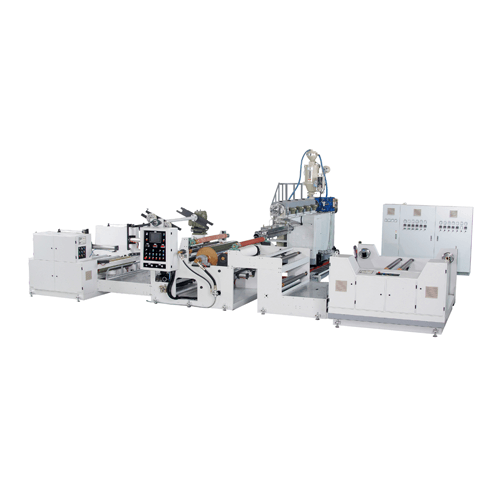

HR系列吹袋机

产品分类 : 吹膜挤出机

Film width available from 2000 ~ 4000mm, excellent for heavy-duty bags. Unique die head and air ring design to achieve stable bubble and better even thickness film and bag. Gear box uses high torque and enforced lubrication system. Automatic surface winder with uploading device. Oscillating haul-off. Blown film machine with oscillating haul-off system, built under the supervision of professional European engineers. AC inverter motor is designed for high production, quality and reliability to produce tubular film. High torque gear box with enforced lubrication system to minimize machine shutdown time. Good mixing performance of screw and barrel results in homogeneity and high output. Oscillating haul-off unit allows minimum web tension that eliminates wrinkle or bulge problem. High volume air ring is designed for ideal cooling efficiency.

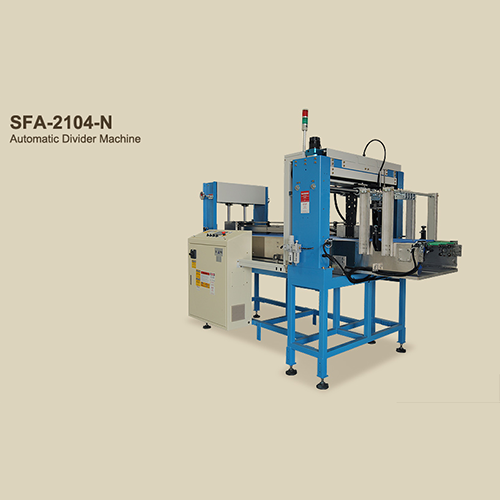

片材自动接合机PTR-500

产品分类 : 淋膜机

Patented Automatic Receiving Mechanism: Performs the material jointing work automatically. Automatic Charging Mechanism: The vacuum robot is used to move the material to the designed position automatically. Servo Transmission Control: Uses 3-axle servomotor to perform high-speed transmission and positioning. Versatile Dimension Flexibility: The parameter fine-tuning can be performed according to the characteristics of different materials. Automatic Feeding Mechanism: Delivers the jointed material automatically. Parameter Storing System: Performs module-based memory for the production figures to facilitate the parameter management.

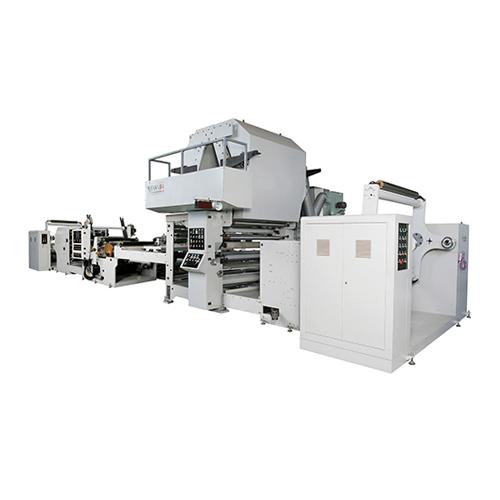

高精度CCD自动对位裁断机-APL-500CCD

产品分类 : 发泡机械

●高精度的机体结构,可作全断及半断加工。 ●上下冲压行程采用四柱高刚性导柱。 ●自动调刀机构,依设定自动调整,精度0.01mm。 ●高速多轴伺服控制系统,效能极高。 ●高阶CCD对位系统,运作速度快,订位精准。 ●裁断主动力为高刚性凸轮机构,稳定性高。 ●安全防护装置,确保人员安全(可选配CE架构)。

高精度小尺寸自动裁断生产线-APL-300

产品分类 : 发泡机械

●伺服裁断机构: 裁断主轴采用伺服马达控制,高效率,高精度。 ●自动送料机构: 采用高阶伺服控制,送料速度快,定位精准。 ●与多轴自动贴合机连线: 与RAL-400高精度多轴自动贴合机连线作同步加工。 ●与自动切片机连线: 与AC-300小尺寸切片机连线作切片加工。 ●二次加工对应: 可对应双站对位裁断加工。

气动油压泵浦

产品分类 : 泵

FUNCTION Use air to drive hydraulic pump. Once the outlet hydraulic pressure reaches the setting pressure, it will stop driving and won't waste any energy. If the outlet pressure is reducing, it will supplement pressure automatically to maintain the pressure continuously. The outlet pressure of the pump and the pneumatic pressure of driving are as direct ratio. The outlet pressure will base on the adjustment of pneumatic pressure to change. The hydraulic pressure (available hydraulic pressure from 60 – 500 Kgf/㎝²) , flow rate of pump and circuit control system will base on the requirement to be different. The circuit control system has the function of check. If there is no pneumatic pressure, the hydraulic pressure will be maintained. The best application is for work clamping systems or hydraulic pressure supply system which needs to maintain pressure for a long time but less operate. It has the function of inspection pressure and can be interlocked with the machine.

电动射出机专用齿轮箱

产品分类 : 变速箱

(1) 采用特殊之设计与制造方式,适合用于高扭矩、高转速之运转环境中。且运转时损耗少低噪音,能提供齿轮减速机较高之传动效率。 (2) 于输入轴(电动马达)与输出轴(连接驱动螺杆和料管)之间,采用三段减速设计。其输入轴与输出轴两者之间的距离空间,恰好正足以涵括马达、减速机箱体及连接螺杆和料管之完整系统配置嵌入其中。形成一U型外观设计,占用最小的空间,达到最大的空间使用效益。 (3) 齿轮元件之设计制作,采用AGMA标准(亦接受客户指定之DIN、JIS标准设计制作),齿轮元件材料采用高品质之低碳合金钢(一般为SCM420等级之材质)制作。齿轮元件经渗碳热处理之后,再经由齿面研磨制程加工后,其精度等级可达AGMA10级以上,确保齿轮减速机运转时之低噪音、低损耗和高效率之特性。 (4) 马达法兰和驱动轴之设计制作,除本型录上之标准形式可供选择之外。亦可依据客户的需求,客制化设计制作,以达到TGSM齿轮减速机最广泛的适用性。