电晕表面处理机 - T型/吹膜机用

产品分类 : 吹膜挤出机

电晕处理机是一种表面改性技术,用于改善附着力处理。 它使用低温电晕放电等离子体来改变表面的特性。 塑料、薄膜、铝泊、铜泊、电镀膜(镀铝膜)、布料(纺织品)或纸张等材料可以通过电晕等离子体,以改变材料的表面能。 所有材料都具有固有的表面能。 表面处理系统几乎适用于任何表面形式,包括3D立体物体、片材和卷材。 电晕处理是塑料薄膜、挤出和印刷加工行业广泛使用的表面处理方法。 又称塑料表面处理机、塑料表面处理机、表面电晕处理机、大气等离子、大电电浆、电晕放电处理、静电处理机、塑料表面放电处理设备、电晕处理机、电晕处理装置、放电机、电火花机。 应用 挤出/押出: .吹膜机 / 吹袋机 / ABA共挤 / Inflation machine .流延膜/片材挤出/挤出涂层/涂层层压/挤出层压/淋膜机 印刷: .联机印刷机/凸版印刷机/柔版印刷机/凹版印刷机/编织袋印刷/标签印刷/溶剂印刷/水性印刷/背对袋印刷 复合与加工 .分切复卷机/涂布/湿式贴合/干式贴合/热贴合/无溶剂贴合/分条机/复合机/涂胶机 机型 CH-800S / CH-1000S / CH-1200S / CH-1500S / CH-2000S / CH-3000S / CH-5000S CH-800T / CH-1000T / CH-1200T / CH-1500T / CH-2000T / CH-2KT CH-3000T / CH-5000T / CH-8000T CH-3KT / CH-5KT / CH-8KT / CH-10KT / CH-12KT / CH-15KT / CH-20KT CH-3KD / CH-5KD / CH-8KD / CH-10KD / CH-12KD / CH-15KD / CH-20KD 适用材料 HDPE, LDPE, LLDPE, MLLDPE, PET, PVC, PP, OPP, CPP, BOPP, PI, PS, PC, EVA, Nylon, PTFE, PU, TPO, TPE, TPO PE woven, PP woven, 编织袋,编织布 Metalized film, FPC, Foil, 铝泊, 铜泊 Non woven, Melt blown, Fabric, textile, 无纺布, 不织布, 熔喷布

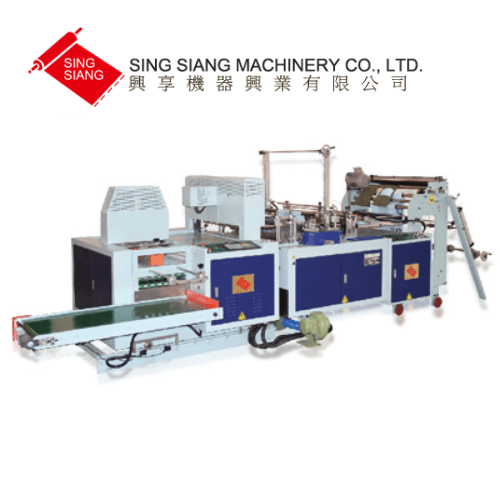

全自动背心式与平口式垃圾袋制袋折叠机

产品分类 : 塑料制袋机

1. 主机伺服马达,德国施克电眼追踪,送料精确流畅。 2. 背心冲口与切袋同步进行,速度快,切口整齐,底封县和袋底之间没有多余切口。 3. 根据需要调整计数设定,一次同时折叠多张袋子。 4. 可依据需要调整折叠次数,2折、3折、4折或5折均可。 5. 第一第二折袋通过伺服控制,时间精确。速度提高,不再出现抓袋时间不准而造成的掉袋现象。

水冷式冷冻机 (YBW)

产品分类 : 冷却设备/工业冷水机

Water Chiller (YBW ) Use the latest European, American or Japanese compressor, available in single and double compressors. The compressors of the double-compressor model can either run alone or together. High-efficient shell-pipe condenser which has heat-transmission function can save energy. Well-designed safety protection. It is also equipped with a digital temperature display indicator and abnormal warning indicators for the long lasting. Applied Machinery: oil temperature, ultrasonic ,high frequency machine/injection /extrusion/blow molding machine

Ultrasonic Metal Welding Machine KWG2620-E

产品分类 : 自动袋焊机

Ultrasonic metal welding, generally for the fusion of low melting point metal materials such as copper, aluminum, etc. Taking the ultrasonic welding metal plate as an example, the two metal plates are overlapped and placed on the base, and the ultrasonic welding head is pressed against the coincident metal plate with appropriate pressure, and a lateral vibration of 20,000 to 40,000 times per second is applied. The two metal plate joints are subjected to high frequency vibration friction and welded. In this welding mode, the solvent is not required, and the welding portion does not need to pass current and heat, and is close to the cold joint, and the intermetallic compound is less likely to occur, and the structure changes little. The welding feature is that the deformation of the joint is less, the material is not melted, and the thermal influence of the material is not significantly changed. The fragile cast structure or the intermetallic compound can be obtained, and the fusion of the foil and the small joint can be achieved without strong resistance welding. Long foil can be applied by roller type continuous welding. KWG0935 model can be applied to lithium battery copper aluminum foil and aluminum nickel sheet welding, copper aluminum foil spot welding, capacitor copper aluminum foil spot welding, etc. KWG2020 model can be applied to lithium battery aluminum shell and aluminum nickel sheet welding, wire and terminal welding, wire butt welding, wire and metal plate welding, metal plate spot welding, etc........