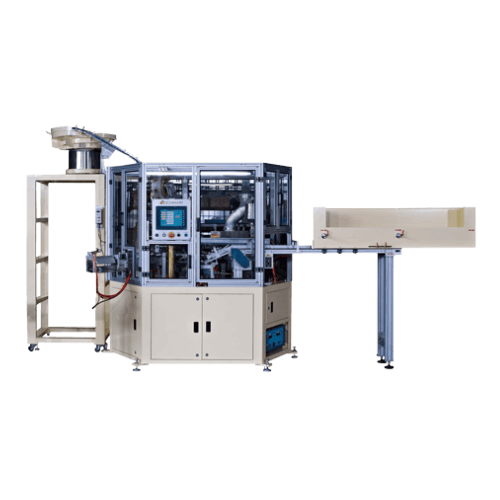

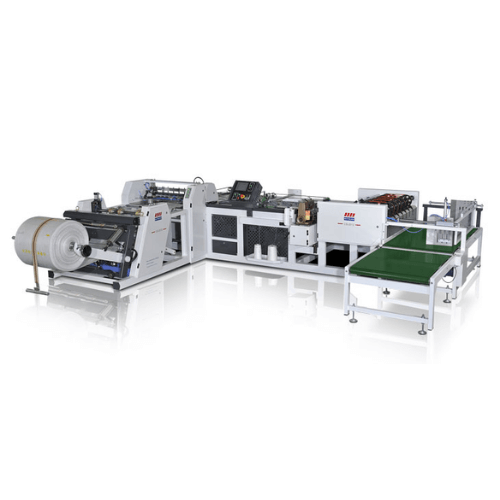

PP Woven Bag Automatic Cutting-Sewing Machine CS-2012(NEW DEVELOPED MODEL)

产品分类 : 工业针织机

Equipped Two Servo Motors Equipped 90゚Bag Transfer Gripper Display Screen Operation Interface High Product Output (32-45 Bag / min) Cusfom-made designs are available

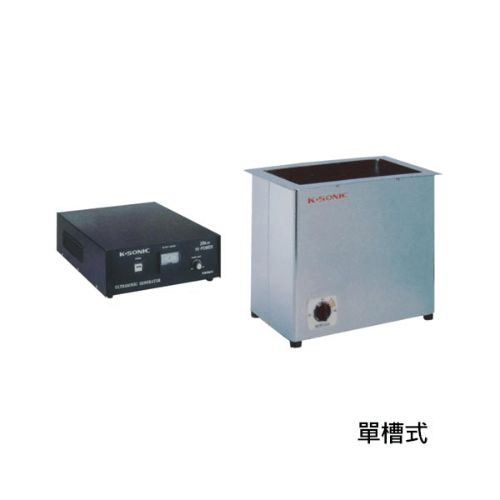

Ultrasonic Plastic Welding Device-Digitized Ultrasonic Module

Automatic frequency self-checking at start-up Full bridge IGBT module are used in the generator to improve durability Automatic tuning (Frequency control). PWM(Plus Width Modulation) amplitude control Protection against Ultrasonic frequency deviation, high voltage and over current. Resonance frequency compensation during welding cycle. Time mode or Energy mode selectable. RS485 communication interface.(Standard Type) Connect to the computer to monitor and transmit each welding parameter and status(EXCEL).(Standard Type) Connected P/C/HMI, one P/C/HMI can control multiple sets of ultrasonic modules (up to 15 units).(Standard Type) Programmable PLC with HMI setting. (Touch Screen Type) 50,000 weld result histories stored. (Touch Screen Type)

JS 602U "U" 型吸管包装机

产品分类 : 吸管包装机

The machine can perform sharp end cutting on the straws, ensuring all sharp ends are packed in the same direction. All machine speeds are variable. High production rate of 350-500 pcs/min. (JS 602U) Automatic machine stop in the event of straw jamming. Automatic product counting. Product quantity preset. Once the present value is reached, the alarm will sound. All rollers are manufactured from aluminum. Suction device for sharp end waste. The machine is easy to operate with minimum trouble. Other lengths are available Please confilm lengths (B) and (C) when ordering. SHARP END CUTTING MECHANISM The machine can perform sharp end cutting on the straw without the need for an additional machine. This allows sharp ends of straws to wrap in the same direction. SEALING WRAPPING MECHANISM The mechanism performs waste suction, pressing and sealing operations. Copper forming pressure roller is designed with 20 cavities. Tetra pack

ULTRASONIC CLEANING MACHINE SINGLE TANK ULTRASONIC CLEANING MACHINE

Overview and characteristics of ultrasonic cleaning machine ※ Ultrasonic cleaning is widely used, such as electrical appliances, electronics, automobiles, industrial machinery, etc.; optical lens degreasing, removal of surface attachments and cleaning parts, using a powerful ultrasonic cleaning machine with the cleaning Engineering to improve the production efficiency and the cleaning quality and working environment by using single-slot, multi-slot, and automatic methods.

立即回收系统

产品分类 : 废塑料回收机

在过去业者生产过程中的边料、水口料因为量少,只能选择丢弃或集中多量再粉碎利用,但这些料囤积在现场易因静电沾附空气中的灰尘,致使再生料产生污点不利使用,且会污染环境、占用空间,再次利用时需经分色、制粒、破坏塑性及再生粒的冗长过程,耗时、耗工且不环保,透过晏邦「立即回收系统」生产,在物性未被完全破坏前,利用小型粉碎机立即将边料、水口料或不良品切割成次料,经过混合比例阀精确控制,将次料酌量加入新料中,不但不影响成品质量,且可减少资源浪费,小型粉碎机占地少、噪音小、耗电量低,可全天候连续使用。 本系统为一小型自动化机边回收系统,由粉碎机、自动填料机、料斗干燥机与混合比例阀四个独立的设备组合而成,亦可配合机械手与输送带一并使用,其主要功能是将塑料射出成型后之水口料立即粉碎后酌量混入新料中,不但不影响成品质量,且可减少资源浪费。 1. 立即粉碎回收、自动输送及干燥一次完成! 2. 粉碎超静音,符合环保标准。 3. 本系统采用特殊设计之小型粉碎机,重量轻、体积小,可随意设置。 4. 新料次料混合比例精确,质量有保障。 5. 次料立即处理,避免污染工作环境,生产有效率,减少资源浪费。

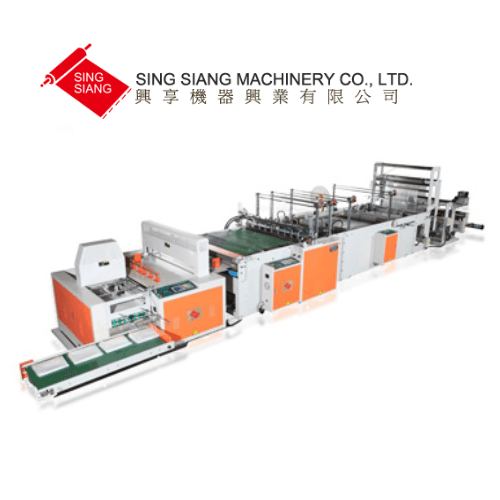

高速底部飞刀系统伺服电机控制封袋机制

产品分类 : 塑料制袋机

‧ Flying knife design, controlled by servo motor. ‧ Germany made photocell-SICK for accurate printed mark. ‧ Automatic lift up reel unwinder with air shaft, reducing the number of empoyees. ‧ Automatic tension control with Japan made inverter system for each line. ‧ Auto stop when film finish or broken. ‧ Collecting conveyor system will be easy for worker to collect bags.