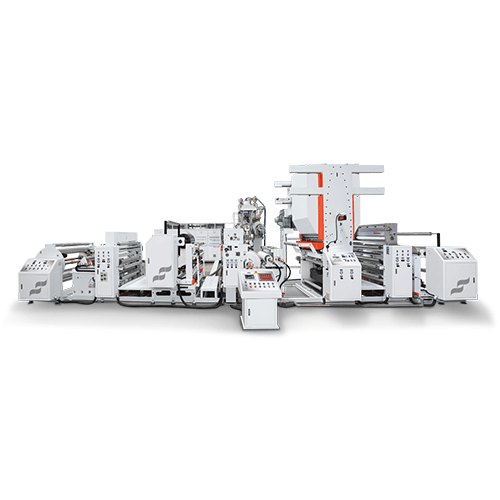

淋膜机

产品分类 : 工业复合机

PLC STATION 1 - Laminating speed control - Extruding speed setting - Laminating parameter setting - Operation temperature setting - Driver status monitoring - Production additives saving - Malfunction warning information - Tension information monitoring PLC STATION 2 - Automatic unwind tension control - Diameter detecting control - Dancer roller tension control - Automatic cutting roll change - Jointing gluing surface check - Automatic pre-drive jointing - Automatic infeed tension control - E/P transducer control PLC STATION 3 - Automatic rewind tension control - Rewind tape tension control - Dancer roller tension control - Automatic cutting roll change - Non-stop roll change - Automatic length counting - Automatic outfeed tension control - E/P transducer control

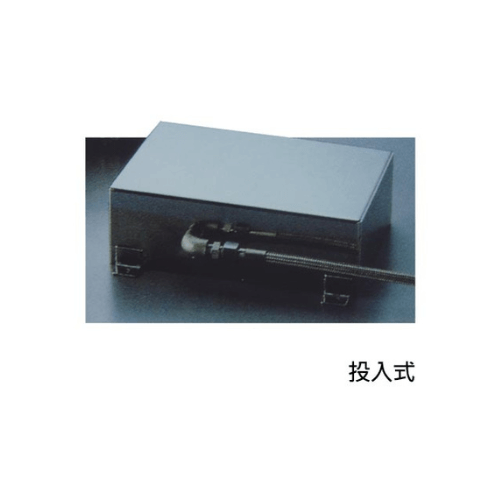

TC5V 阀门控制器-8段

产品分类 : 控制设备

输入讯号选择( AC220 / 110 / DC24 / 开关式) 输出模式选择( AC220 / 110 / DC24 / 开关式) 时间显示可调至小数点第一位时间计数可选择累加或倒数三种控制模式选择可选择保压模式电子式开关延长使用寿命( 电流可达600 mA ) ( 标准) 可选用机械式开关,输出电流较大( 选配) 长新

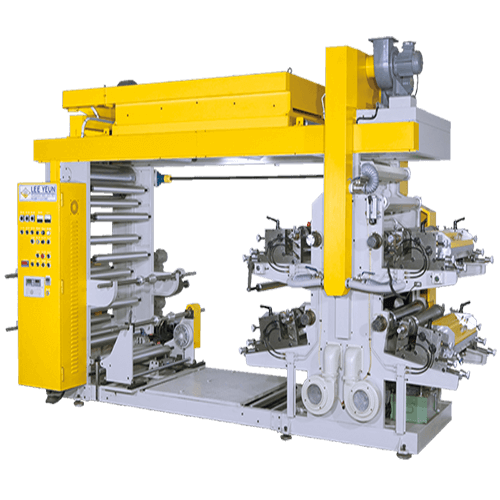

独立凸版/胶版印刷机FSP-5000

产品分类 : 柔版印刷机

这是比较起LL机型更加进阶的凸版/胶版印刷机,标准配置日本原装进口的放料自动张力控制器,和油压式对边控制器,双收双放卷料座使得操作上更加有效率。膜料进度印刷座前有香蕉轮做膜料的延伸的更加平整,每个印刷座都有独立的干燥管做印刷膜料的初步干燥,机器附有T5灯管保持工作场所的明亮,上部有过头干燥箱加大加热功能配合鼓风机确保膜料可以配合高速印刷做干燥。机器中间没有设置工作台,操作人员可以直接用推车将膜料推至放料座前做放料。

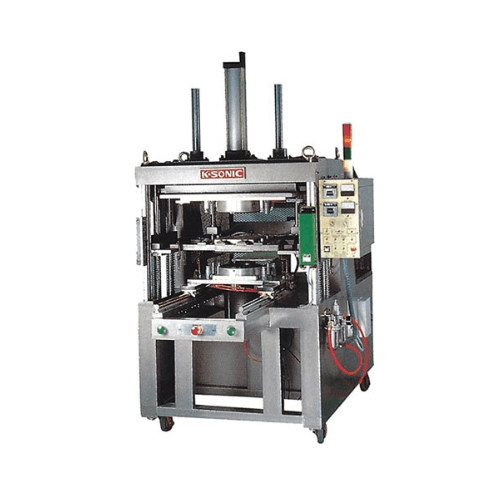

Hot Plate Plastic Welding Machine KH-31

The machine is constructed of main body, hot mold set and upper & lower fixtures. Only upper fixtures declined by cylinder. The welding part's surfaces melted in proper welding time when pressed against the hot plate The hotplate retracts and forced welding parts together in proper holding time Enable to weld two mold cavities in one stroke

凹版轮转印刷机(WPR-MV系列)

产品分类 : 凹版印刷机

玮礼公司在凹版轮转印刷机的开发及技术上有多年的丰富经验。所有的印刷设备结合了中央控制系统使得操作简易,简易明了的数据及功能显示在人机触控萤幕,全机以PLC做同步的中央控制,以及自动化的套色系统和警报功能可有效率的管理印刷品质,此外特殊的废气热能回收系统,回收率最高能达到77%,大大的降低生产成本的损耗提升产能。

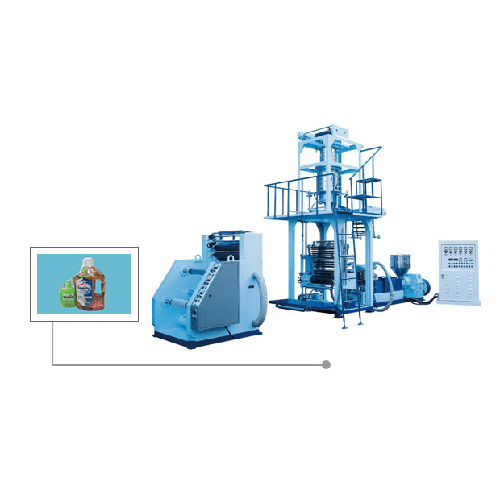

JS 336S PVC收缩膜制造机

产品分类 : 薄膜和片材挤出生产线

PVC Shrinkable file offer many excellent benefits, such as glossiness, high transparency, durability, water resistance and easy control of shrinkage. They have been applied to a wide variety of product packaging, such as foodstuff, beverage bottles, sporting goods, etc. For over 20 years, jumbo Steel has dedicated itself to the research of production technology for PVC shrinkable film. We have made great improvements in product prescription and machine performance, upgrading the quality and efficiency of PVC shrinkable films.We have a strong background and engineering experience for whole-plant planning and equipment supply. Jumbo Steel PVC shrinkable film production equipment has been sold worldide, and has earned a reputation for its superior machine and outstanding production know-how. In addition to supplying the most dependable machinery, we also place emphasis on the technological support and complete production upgrades. This allows our customers to start up or resume production very quickly. Jumbo Steel has a proven tradition of pursuing excellence and improving the PVC Shrinkable Film industry, and it will continue to develop its engineering capabilities and raise industry standards.

真空压力比例阀(0~ -101kpa)

产品分类 : 指示器和传感器

该电子式真空比例阀为一个闭回路设计,由两个电磁阀、压力传感器以及电子回路控制所组成。根据输入讯号渐大,真空用电磁阀为开启状态,破真空用电磁阀为关闭状态。因此,抽取真空压力时透过真空用电磁阀作用于气导式内部活塞,并致使与活塞连动的排气阀打开,进而将大气转换成负压,并通过压力传感器反馈至控制回路。在此 ,该比例阀作动过程中会进行修正动作,直到真空压力与输入讯号成比例。高鹿比例阀输入信号提供了0-10VDC(电压) 与4-20mA(电流) 及 RS485 ModBus 通讯选择。监控输出则有 1-5V、0-10V及4-20mA 的选择。 专门的真空控制方法 真空的使用在许多测试、制造和工业过程中很常见。高鹿专注于以三种不同方式进行闭环真空控制 线上(管路内)真空调节 闭环的真空电控比例阀可根据使用者输入的命令信号来调节真空泵的真空度。高鹿 的真空比例阀的真空度调节与命令信号输入成正比。真空度范围可由客户选择,最低可到14.4 psi。真空压力比例阀的回馈信号可用于真空数据采集。 QKL-B3V真空电控比例阀 是一种高精度的真空比例阀, 用于直接控制和监控真空度。高鹿的QKL-B3V大流量高精度真空电控比例阀让使用者透过类比信号或RS485来调节真空度。 QKL-B3V真空压力比例阀可用于调节真空应用在真空干燥, 真空包装, 灌装等应用上。如需订制真空度调节范围,请联系我们的技术团队。 真空破坏 和线上的电子式真空比例阀相比,在一些应用场景如测试设备和PVC管和医疗管冷却箱里,真空泵会安装于连接测试腔体同时持续运作。这些测试腔体通常会些微的漏器。这时真空可经由控制流进去腔体的空气量来控制,通过我们的闭环真空破坏。腔体里面的真空可经由使用者给予的输入信号道闭环的电子真空破坏器来控制。这个装置可维持腔体内的真空度同时可透过回馈信号来显示腔体内的真空度。高鹿的FC系列流量比例阀以真空破坏的方式来调节腔体真空度,实现高重复性,高精度,高真空度范围的简易调节。请参考网页https://www.genndih.com/chs/流量比例阀.htm 真空产生 高鹿的闭环真空比例阀搭配外部真空传感器可连结至客户提供的真空空间使用形成一个闭环的真空发生器。采用多阶段的真空发生器和高鹿的闭环控制器方案可实现更精细的真空度控制。 QKL-B3V 真空比例调节阀可透过外部的真空传感器来实现高精度且远端的真空控制。如需大流量的真空控制,我们也提供大流量的真空电控比例阀。

THH 高速型电晕处理机

产品分类 : 表面处理设备

适用 吹膜机,切片机,淋膜机,印刷机,贴合机,涂布机 输出功率 8-20 KW 处理宽度 1000~3000 mm 处理速度 100~300 米/分 处理效果 38~46 达因 12道放电

Sun Roof Related Parts

产品分类 : 注塑产品

This product is a sunroof front pillar, specifically designed for automotive sunroof systems to provide structural support and fixation, ensuring stable sunroof operation and maintaining vehicle rigidity. It is manufactured using high-strength PP+GF (Glass Fiber Reinforced Polypropylene) material, offering lightweight properties, impact resistance, heat resistance, and low deformation rate, effectively enhancing vehicle safety and durability. Produced with a 1600-ton large injection molding machine, this product guarantees high precision, consistency, and durability, making it suitable for various sunroof systems, including panoramic sunroofs, electric sunroofs, and manual sunroofs. Additionally, its design features excellent drainage performance, efficiently preventing water accumulation, leakage, and flooding issues, ensuring long-term stable operation.

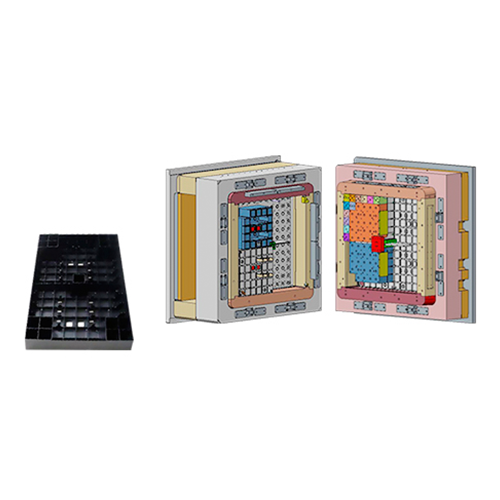

85-150 ton injection molding machine product

产品分类 : 注塑产品

This 85-150 ton injection molding machine is designed for high-precision plastic product manufacturing, including automotive components, electronic parts, appliance housings, medical devices, and consumer goods. Equipped with a high-efficiency servo-driven system, it ensures stable injection pressure and precise control, delivering superior molding quality. With a high-rigidity clamping structure and an optimized hydraulic system, this machine offers durability and operational efficiency. It supports various plastic materials (PP, PE, ABS, PC, PA, etc.) and can be customized with multi-stage injection units and robotic interfaces for full automation, reducing labor costs and increasing productivity. Ideal for OEM manufacturers, plastic molding factories, and precision molding industries, this model meets modern production demands with efficiency and precision.

油压式强力加压利拿式密练机

产品分类 : 分散捏合机

此机械适用于各种、塑胶及化学工业之沥青混合之混合及制造。 减少的良好性和均匀性。比一般性混炼的时间增加可混色容易。比一般的压力混炼可以加倍以上的时间,混匀度与混炼性更好,练机密练加盖2魔梯等特点

制袋机HY7/SP-150H

产品分类 : 封口机

该HY7/150L的容量为25-30袋/分钟,与长度调节和自动袋收集系统。该装置还可以配备自动着嘴和底部的折叠系统,制袋生产速度更快,更方便。我们还可以通过伺服电机系统,提供高容量转换线与40支/分钟。

ULTRASONIC CLEANING MACHINE BOX TYPE ULTRASONIC CLEANING MACHINE

Overview and characteristics of ultrasonic cleaning machine ※ Ultrasonic cleaning is widely used, such as electrical appliances, electronics, automobiles, industrial machinery, etc.; optical lens degreasing, removal of surface attachments and cleaning parts, using a powerful ultrasonic cleaning machine with the cleaning Engineering to improve the production efficiency and the cleaning quality and working environment by using single-slot, multi-slot, and automatic methods.