精密四柱式平面油压裁断机-CSS-202B

产品分类 : 发泡机械

●机械机体,使用特殊钢质制成,而且经过严格处理耐冲压,永久保持精密度。 ●上下行程采用钢柱为轨道,精密度高,永不摇晃。 ●两柱油缸,出力平稳,扭力大。 ●冲压时,有两段慢速功能,无震动,可减少裁垫损耗,产品无须边。 ●特有自动润滑系统,增长机械寿命。 ●工作物裁断调整器,简便,准确,10秒内可调整到适当深度。

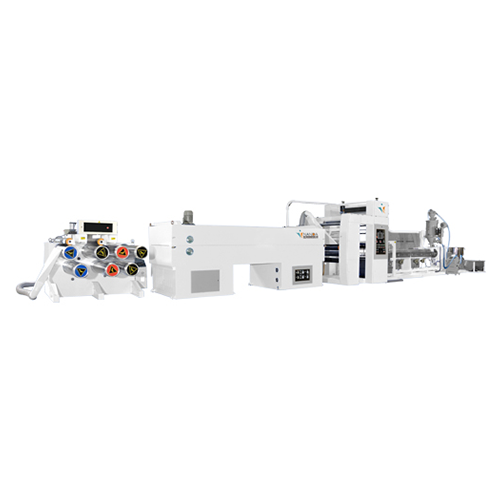

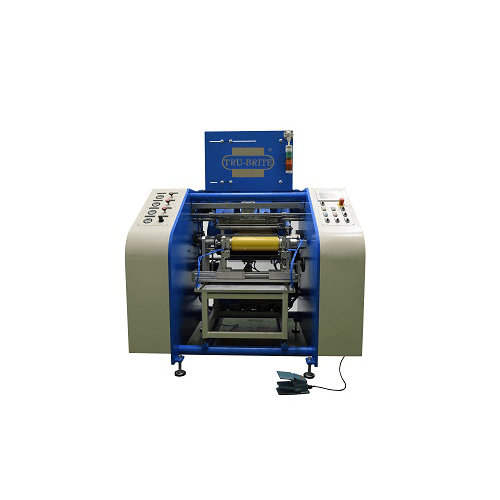

高精度自动裁切机TRC-350

产品分类 : 发泡机械

自动对边张力控制系统,是针对卷材设计,可使收料控制更加稳定流畅。本机经特殊设计,及精密加工,裁切精度稳定性极高,成品良率可达百分之百。采用新式触控萤幕,具有亲和之操作介面,操作简便易上手,降低人员训练之成本。

实验型押出机(PR50)

产品分类 : 塑料造粒机

我们的主要产品之一,可以连接到许多不同的机械生产线,包括造粒生产线,母料机和复合机。我们的机器可以加工许多不同种类的颗粒,包括:(EVA,HDPE,PVC,PE,CaCo3硫等)PR系列是双螺杆给料机和挤出机的组合,可以加工大量的原料由班伯里密炼机生产。这种双螺杆设计的原料稳定喂料,降低了原料供应不足的风险,进而提高了成品率和产品质量。此外,通过这种独特的设计,可以减少劳动力成本和时间,创造稳定的生产线。

立式塑胶、立式射出成形系列 YHL 系列

产品分类 : 立式注塑机

- 立式直立锁模,直立射出的机体方式,结构简单,宽台面。 - 采射出中心偏位元的设计方式,使三面空间更加开放,能适用长条状汽车密封条接角成型或带有导线产品成型,让成型作业更加容易。 - 立式塑胶射出机,射出系统采标准、模组化设计,通用各类型的嵌件注塑成型,塑胶成型能力特优。 - 立式橡胶射出机,射出系统采螺杆进料,柱塞射出二阶段的设计,能适应不同硬度的橡胶材料,橡胶注射稳定精确。 - 最优化的设计方案,如锁模/注射/塑化等单元最可靠的射出成型设备之一。

COLD DECK WITH 16 VALVE GATES

Shut-off nozzle design:Don't need to cut scrap. System temperature analysis:High efficiency heat isolation and cooling, uniform heating system. Module design of Cold Deck:Quick installation and easy to maintain.

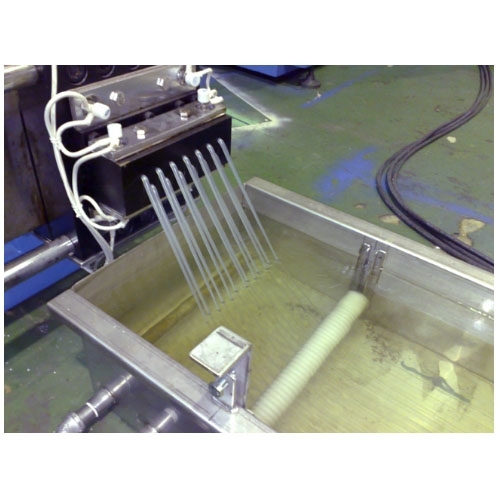

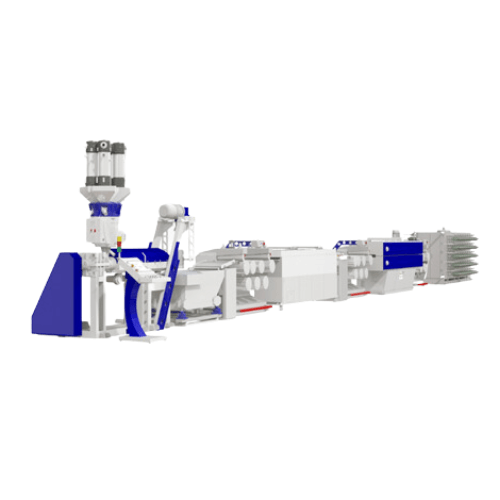

Danline Monofilament Line (JC-MND Series)

产品分类 : 长丝与纱线挤出生產线

JC-MNP系列Danline单丝生产线采用双阶段拉伸和热定型设计。该生产线专为处理各种工业应用而设计的高抗拉强度单丝。

PP Woven Bag Related Machinery - JLJBCM SERIES

产品分类 : 塑料制袋机

Alloy steel knife for good cutting section Equipped cross or circle punching device Customized design

多轴自动贴膜机AFC-700LE

产品分类 : 切割机

Patented Bonding Mechanism: In achieving higher bonding accuracy and without air bubbles. Fully Automatic Tension Control System: The tension of materials for each axle is controlled in an automatic way. Servo Transmission Control: Dual-Axle servomotor is used to achieve synchronized alignment control. Diversified Size Option: The parameter fine-tuning can be executed according to the characteristics of different materials. High Clean Bonding Environment: Which meet high-cleanliness bonding space requirements in providing higher Y-Rate. Unique Material Handling Techniques: Which is designed according to the characteristics of optical film to avoid scratching the material.

FOUR-SHAFTS TYPE AUTOMATIC CLING FILM REWINDER (ADJUSTMENT) (AH-FW)

产品分类 : 分切机和复卷机

AH-FW, the four-shaft type automatic rewinding machine. It's suitable for rewind PE, PVC cling film. The machine specifications are customized accord to client's needs. AH-FW (20-30): Mother roll's available width from 200-300 mm; finished paper core's length from 210-310 mm. AH-FW (20-50): Mother roll's available width from 200-500 mm; finished paper core's length from 210-510 mm. It's a fully automatic model. Users only need to input paper cores and materials, machine will feed material, rewind, cut and unload finished products automatically. Besides, it has various switches: Auto/Manual mode Press roller ON/OFF Feeding ON/OFF Brake ON//OFF Small press roller ON/OFF With the above switches, it will be fast and convenient to adjust machine. What’s more, AH-FW has a curling device. The device will make a curl at the end of the roll, makes it convenient to start using the cling film. Machine shows total data and production values on the touch screen, users can control the machine status anytime. Welcome to consult machine with us. We will at your service.

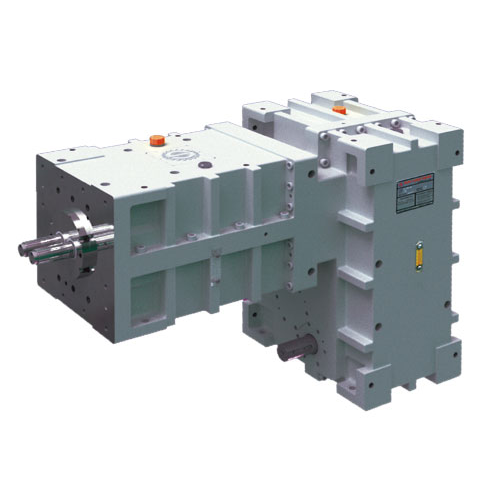

异向平双螺杆押出机齿轮箱

产品分类 : 变速箱

PET吹瓶机系列-TEM08S2-88

产品分类 : 自动吹瓶机

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

立式三柱转盘射出机

产品分类 : 立式注塑机

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put-in, take-out products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production.