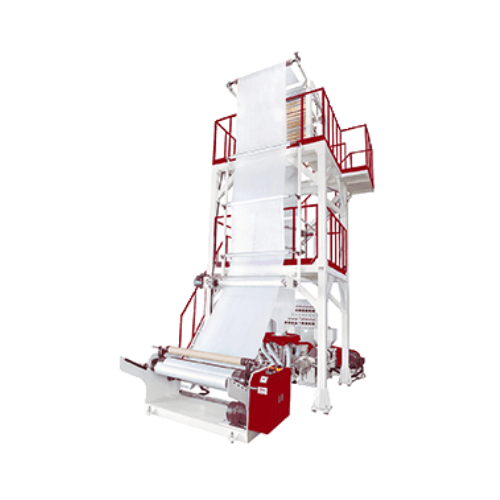

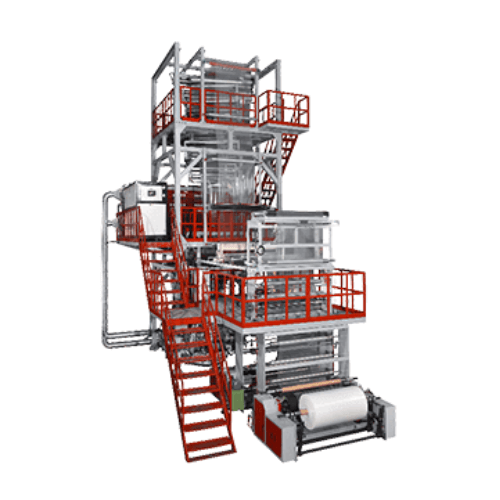

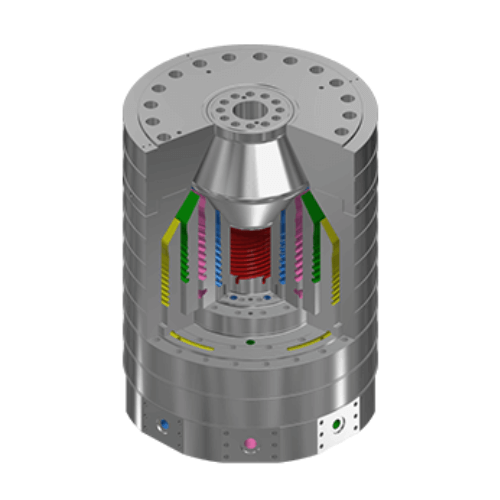

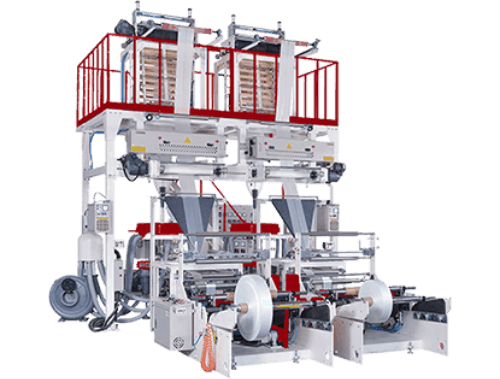

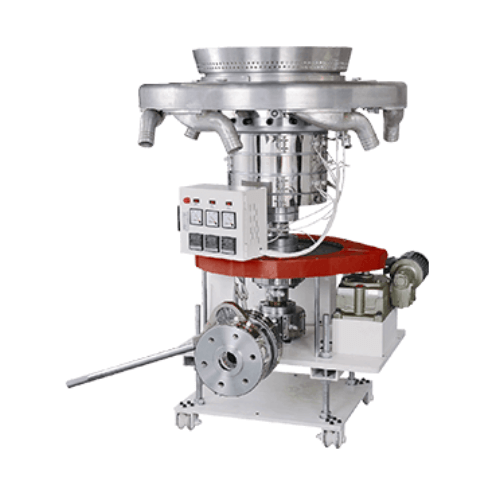

Offering a wide range of Plastic Film Blowing Machines and its related components which are available to all the countries is what HSIN LONG keeps working on. For Three Layers ABA Co-Extrusion Blown Film Machine which characteristic is focus on its well performance and changing speed of the materials is extremely fast. It saves more time for customers to change the material and shorten the labor time. Further, It lowers the material change time and reduces the material wastage as well which is the biggest advantages of this type of plastic film blowing machine.

塑胶吹膜机的主要生产制程是将高分子材料制成塑胶薄膜。首先将原料放入吹膜押出机的料斗中。在螺杆的输送下,原料会被熔化并成为熔融物。将原料流到过滤器,将杂质去除,使原料保持干净,以利后续的吹膜制程。材料从挤出机模头形成气泡管,由收料装置拉起并压平。按照卷取路径,塑料薄膜卷成完整的卷,这是塑料薄膜生产的最后一道工序。这是塑胶吹膜机制造薄膜的基本生产流程。此外,依据塑胶膜的用途,选择的塑胶膜吹膜机型式也会完全不同。

主要应用食品包装、工业,建筑、农业、医疗用膜,并以外销市场为导向。现阶段积极投入纺织、4C、光学及新行动能源等领域高机能、高附加价值薄膜有关押出机组、系统、模具之研发与生产。

食品包装用阻隔膜

食农用薄膜

食医用薄膜

- 快速换料

- 降低材料成本

- 针对不同膜宽的吹膜机提供客制化服务

Model |

HL65W1200 |

HL55W1000 |

HL45W650 |

| a) Material To Be Used: | HDPE/LDPE/LLDPE | HDPE/LDPE/LLDPE | HDPE/LDPE/LLDPE |

| b) Layflat Film Width: | MAX:1100 | MAX:900 | MAX:550 |

| c) Extrusion Output: | MAX:120~140Kg/Hr | MAX:60~80Kg/Hr | MAX:38~45Kg/Hr |

| d) Film Thickness: | HDPE: 0.015mm~0.15mm LDPE: 0.02-0.2mm |

HDPE: 0.015mm~0.15mm LDPE: 0.02-0.2mm |

HDPE: 0.015mm~0.15mm LDPE: 0.02-0.2mm |

EXTRUDER |

|||

| a) Screw Dia.: | 65mm, L/D=30:1 | 55mm, L/D=30:1 | 45mm, L/D=30:1 |

| b) Gear Box: | 50HP | 30HP | 20HP |

| c) Driving Motor: | 50HP | 30HP | 20HP |

| d) Air Cooling Fan: | 4pcs | 3pcs | 2pcs |

EXTRUSION DIE & COOLING EQUIPMENT |

|||

| a) Die Head: | HDPE150~180mm | HDPE90~120mm | HDPE50~80mm |

| c) Filter: | 65mm | 55mm | 45mm |

| d) Air Blower: | 7.5HP | 5HP | 3HP |

CONTROL PANEL |

|||

| a) Type: | Individual Box | Individual Box | Individual Box |

| b) Heating Zone: | 7 Heating Zone | 6 Heating Zone | 5 Heating Zone |

TAKE-UP UNIT |

|||

| a) Type: | Tower Fixed Type | Tower Fixed Type | Tower Fixed Type |

| b) Tower Height: | 6.5M | 5.5M | 3.5M |

| c) Take-Up Roller Width: | 1200mm | 1000mm | 650mm |

| d) Take-Up Motor: | 1HP + Inverter Control | 1HP + Inverter Control | 1/2HP + Inverter Control |

| f) Take-Up Plate: | Wood Type Aluminum Roller Type |

Wood Type Aluminum Roller Type |

Wood Type Aluminum Roller Type |

| g) Guide Roller: | 20kg/cm Torque Motor | 20kg/cm Torque Motor | X |

| h) Stabilizer: | M765 | M650 | M450 |

WINDING UNIT |

|||

| a) Type: | Single Station Manual Type | Single Station Manual Type | Single Station Manual Type |

| b) Working Method: | Surface Friction Type | Surface Friction Type | Surface Friction Type |

| c) Wound-Up Dia: | MAX. 800mm | MAX. 800mm | MAX. 800mm |

| d) Winding Motor: | A.C 1HP+TQ TQ Motor Control | 40kg/cm Torque Motor | 30kg/cm Torque Motor |

| e) Winding Shaft: | 2pcs | 2pcs | 2pcs |