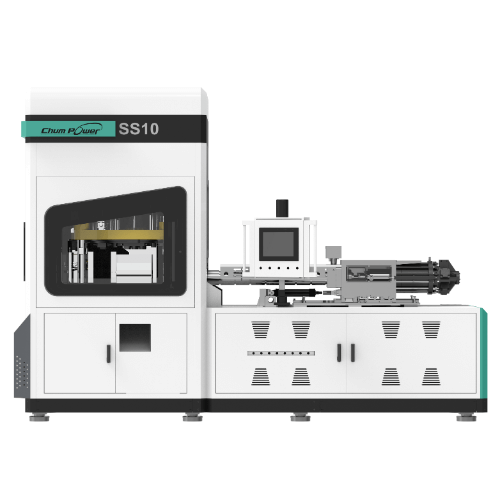

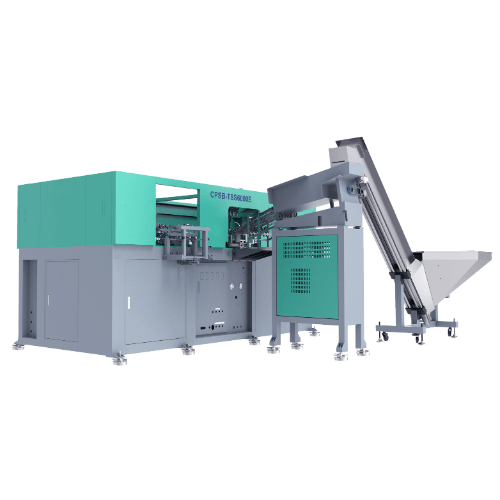

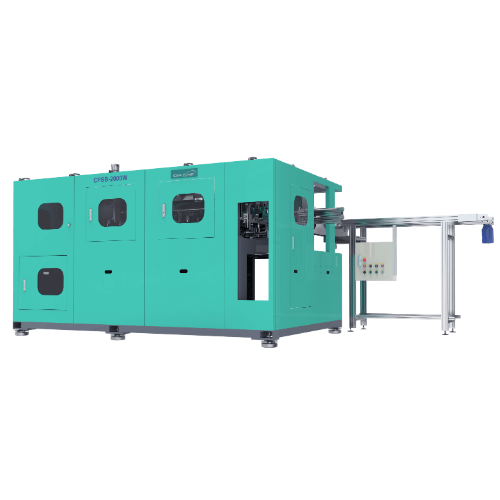

FS-BT-S is equipped with 2-station servo table and side-blow system. After preform injection, the servo table rotates 180 degrees, a servo screw then transfers a neck plate with PETIPC preforms to the side-blow station for blowing bottles. Using side-blow system is available and flexible for a bigger work place, and optional devices; gate trimmer (preform tail cutting device) and product conveyor can easily be mounted inside the machine to go on the automatic production. This model is good for small containers with short cycle time.

Jar/wide-mouth bottle available, FS-BT-J has the same benefits of FS-BT-S, but is for wide-mouth jar applications, and it's a stronger machine with higher injection capacity and stronger clamping force.

Innovative approach by 2-station machine operation, FS-BT-S/FS-BT-J need less neck cavities, less mold cost, and has a more effective mold width to save the total cost. Mold cost is an important investment in running diversified and various products lines. The tooling'mold cost in our simple and innovative system is the lowest of all.

Bottle Condition for FS-BT-3S :

Round bottle with standred neck

| Volume(ml) | Height(mm) | Neck(mm) | Pitch(mm) | B/DIA(mm) | Cavity(pcs) |

| <2000 | 300 | <50 | 150 | <120 | 2 |

| <500 | 300 | <38 | 75 | <70 | 4 |

| <200 | 300 | <22 | 50 | <45 | 6 |

| <50 | 600 | <15 | 37.5 | <33 | 8 |

Bottle Condition for FS-BT-4S :

Round bottle with standred neck

| Volume(ml) | Height(mm) | Neck(mm) | Pitch(mm) | B/DIA(mm) | Cavity(pcs) |

| <1500 | 300 | <45 | 105 | <100 | 4 |

| <400 | 300 | <38 | 70 | <65 | 6 |

| <200 | 300 | <22 | 52 | <65 | 6 |

Bottle Condition for FS-BT-3J :

Round bottle with jar neck

| Volume(ml) | Height(mm) | Neck(mm) | Pitch(mm) | B/DIA(mm) | Cavity(pcs) |

| <1500 | 300 | <83 | 125 | <110 | 2 |

| <1000 | 300 | <63 | 98 | <94 | 3 |

| <600 | 300 | <38 | 65 | <60 | 4 |