CHINAPLAS 2025 | Innovation and Collaboration for Sustainability

Experience the future of plastics at #CHINAPLAS2025! Shenzhen World Exhibition & Convention Center (Bao'an), Shenzhen, PR China 15-18 April, 2025 Let's embark together on this journey of innovation, collaboration, and sustainability! See you there #PlasticsInnovation #CHINAPLAS

Rotary Table Injection Molding Machine | TAIWAN KINKI

MACHINERY IN THE VIDEO: Rotary Table Injection Molding Machine with Full Auto System from TAIWAN KINKI (TKC) [TAIWAN KINKI LINES OF BUSINESS] Production of vertical plastic injection molding machines. Design of automatic injection molding machinery. Turn-key plants for accessories and peripherals for injection machinery. Injection mold design and manufacturing. Electrodeposition, powder coating, baking enamel, and leather treatment. Agency of the vertical injection machine and Zinc alloy coating. [APPLICATIONS] Especially suitable to manufacture Automobile Parts [TAIWAN KINKI (TKC) BACKGROUND] TKC had over 40 years of experience in Vertical Injection Molding Machine manufacturing. The company offers a full series of vertical injection molding machine portfolios including Standard, Slide, and Rotary table models. TKC also offers mold design and a full auto system for customer's products.

Exploring the Future of Packaging Machinery with Thomas Dohse | Shanghai swop Interview

In this exclusive interview at Shanghai swop, we sit down with Thomas Dohse, a key figure from interpack, to dive deep into the future of packaging machinery and the emerging trends shaping the industry. Discover the fascinating highlights of the swop exhibition, including innovative technologies and unique insights into the latest advancements. Thomas also shares his perspective on the resurgence of globalization, which has taken a new form through fragmented and decentralized transactions, creating fresh opportunities for businesses worldwide. Finally, Thomas gives us a sneak peek into the 2026 interpack, unveiling its central themes and what we can look forward to in this global event. Don’t miss this insightful discussion that combines cutting-edge trends with a vision for the future of packaging!

Ultrasonic Metal Welding Machine-ULTRA6200-M-WT | MING JILEE

ULTRA6200-M-WT Ultrasonic Metal Welding Machine

Double Lines T-Shirt Bags Making Machine:ST-88-G2 | COSMO

Fully Automatic High Speed Double Lines T-Shirt Bags Making Machine with Hot Slitting & Side Gusseting Device. Model : ST-88-G2 Machine Features: https://www.cosmo886.com.tw/en/products_i_High_Speed_T-Shirt_Bag_Making_Machine_with_hot_Slitting_and_Side_Gusseting_Unit_ST-88-G2.html ➤Contact Us COSMO MACHINERY CO., LTD. Web: https://www.cosmo886.com.tw

Assembling Video of Two Platen Injection Molding Machine - 3000TP | CLF

【ASSEMBLING VIDEO】 Two Platen Injection Molding Machine 3000TP from CLF. CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance.

Plastic Recycling in Japanese Market at K 2022 | POLYSTAR

We were glad to have an interview with Mr. Kenji Murai, agent of POLSTAR in Japan, who shared his observation of plastic recycling in the Japanese market and his experience doing machinery business.

Customization & After-sale Service | GENIUS

More and more countries request all plastic-made products to be fully recycled; therefore, plastic recycling machines have been important. Mr. Peter Tsai, the general manager of Genius, explained the best seller “Single Stage Cutter Compactor Plastic Recycling Machine” as known as KRIEGER series in their product lines. This machine is capable of recycling HDPE drums and films with superior features, such as Italian-made heater, extruder-degassing vents, dual piston filters. With excellent customer satisfaction and customization service, Genius awarded an order from a returning Japanese client again. According to the language and the use habits, the parts of the machine have been installed with many Japanese brands in order to lessen obstacles while Japanese employees operate the machine. Moreover, Peter has expressed how Genius values customer satisfaction, customization service and after-sales service in the interview. Through this video, you will be showcased how Genius is running the testing of Single Cutter Compactor Machine before shipment. 【Brief Intro】 Genius Machinery specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipment. 【Video Outline】 00:00 - Introduction 00:31 - Machine Testing & Superior Features 02:10 - Conveyor Belt 02:19 - Compactor 02:50 - Extruder-degassing 03:19 - Dual Piston Filter 03:40 - Pelletizer 04:18 - Details of customized control panel 05:21 - Materials Process & Applications of Machine 06:27 - After-sale service for installation & maintenance 08:05 - Messages to customers

PP Flat Yarn Extrusion Line & Raffia Tape Stretching Line Plant|HAO YU

The extrusion line has maximum PP melting output. Capacity is 160 ~ 520 kg/h and the unit is equipped with a screen filter changer and rotary blade slitting system. The machine has less down time and prevents production loss. The pressure rollers of the take-off unit are pneumatically controlled, and have synchronized control electronic system. Available to meet special requirements. 【Company Introduction】 Hao Yu Precision Machinery Industry Co., Ltd. is a leading manufacturing of PP and PE woven bag machinery and whole-plant equipment. Since its establishment 1980, HAO YU has been dedicated to the research and development of high performance machinery.

Solventless Lamination - Webcontrol

Solventless Lamination - Solventlless Laminator-LM-SF1300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Solventless Lamination since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Lamination with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Lamination service ensure our worldwide customers must be satisfied.

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

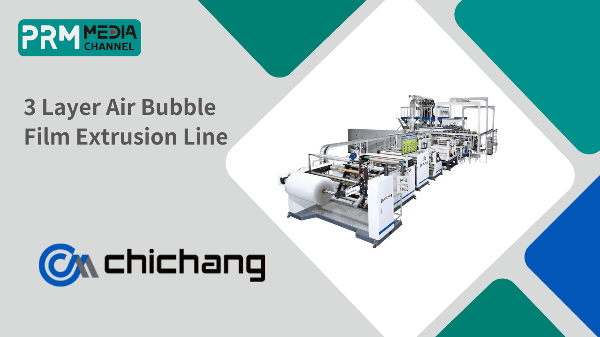

3 Layer Air Bubble Film Extrusion Line | CHI CHANG-

MACHINERY IN THE VIDEO: 3 Layer Air Bubble Film Extrusion Line from CHI CHANG MACHINERY APPLICATIONS: The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive. Agricultural sector (green house) with anti-UV additive. Covering of swimming pool with anti-UV additive. Typical packaging with anti-shock, anti-abrasion and anti-crushing functions. Laminated with paper, PE woven and aluminum foil for making envelope.

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

All electric blow moulding 20L jerrycan energy saving, no hydraulic oil, no pollution, industry 4.0 | FONG KEE

Model No : FK/EHB-55G-100G-55GT20SD Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system.

T-Shirt Bag Making Line with Carton Packaging Line|JIT-SS 4 sets full auto. in-line|JANDI'S

#PlasticReuse #MachineManufacturer #PlasticRecyclingMachine 00:00 Opening 00:08 Blown Film 00:28 Machine current speed 00:37 Cutting, Sealing & Punching 00:54 Sending finished bag to Carton Packaging Section 01:07 Take-up Tower & Printing 02:27 Carton Packaging Proccess 05:04 Ending --- Website : www.jandis.com.tw & www.inflationmachine.com Facebook : www.facebook.com/JANDIS.JIT Email : [email protected]

Side Entrance Two Stages System | GEOR DING

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more. We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.

Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

What is Biodegradable Plastic & Bio-based Plastic | PRM What to Say EP9

What are the biodegradable plastics? Are biodegradable plastics recyclable? Are biodegrdable plastics environmentally friendly? What are the types of biodegradable plastics? Where to use biodegradable plastics? We heard your questions and made a research for you, looked for the answers of common questions about biodegradable plastics. We also evaluated difference and similarities of bio plastics and biodegradable plastics. Let's take a look at the video and find out more about these two types of materials!

PET Recycling Innovations and Sustainability through Plastic Recycling | PARTICO

This time our guest is Partico Machinery Inc. Partico stands out with its customized thermoplastic recycling machines in Taiwan with over 25 years of experience. Dear Denny Chang and Lucy Huang, the sales representatives of the company, were really intimate to share their company's innovations and investments in R&D. By developing PET vacuum extrusion pelletizing system, Partico makes a distinction from other traditional manufacturers and creates its own market value. As a manufacturer of extrusion pelletizing machines, Partico is dedicated to calling for the importance of sustainability. The purpose of the company is not only to manufacture plastic recycling machines for the industry but also to assist in environmental protection with efficient machinery, as a part of the company's ESG contribution. The most important thing is that Partico is familiar with various materials that its machines can recycle. In addition, Partico is also capable to plan suitable conveyor systems for the customers according to their materials characteristics and applications, so they do not need to worry about the overall planning of equipment. In recent years, the main trend in the PET recycling industry is to apply pellets to make food contact materials. One of Partico's goals is to get FDA certificate, which refers to manufacturing recycling machines that recycle PET flakes for food packaging applications. We have more to share, then let's take a look at this intimate interview and learn more about Partico and its innovative contribution to the plastics recycling industry.

3000 Ton Plastic Injection Moulding Machine | CLF

3000 Ton Plastic Injection Moulding Machine - Chuan Lih Fa CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W | MING JILEE

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W For Further information:https://www.mingjilee.com/en/product/Wire-Impulse-Bottom-Bag-Sealing-Machine-with-Flying-Knife-Cutter.html

Bag on Roll Making Machine-Draw tape Garbage Bag|Plas Alliance Ltd.

Are you looking for plastics and rubber suppliers for machinery, molds, raw materials, auxiliaries, and so on? Here is PRM-TAIWAN B2B Platform only one click away. Visit our website now and search for your Taiwanese suppliers. Learn More : • Bag on Roll Making Machine|Draw tape G... ------------------------------------ Draw tape garbage bags are advanced type of garbage bags which has strong tensile strength and puncture resistance, and controlled elongation for volume. The draw tape can be pulled and knotted for secure closure. Bag on roll are good and compact for transportation and end use for household consumers. - Bag making application - Draw tape garbage bag on roll - Folded draw tape garbage bag

Crystallized Hopper Dryer(CHD) | YANN BANG

Our PET / PLA Crystallizer is a closed-loop heating system continuously to re-crystallize PET amorphous resin and covert it into crystalline state. FEATURES The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper.The unique mixer stirs the resin simultaneously while the unit is drying.To crystallize,it increases the I.V. value and speeds up the crystallization. To Dry the mixer dries evenly and shortens the drying time. YANN BANG Crystallized Hopper Dryer is the best choice for PET users. 1. SAVE COST. With YANN BANG's patented drying technology,the crystallized hopper dryer mixes the resin evenly while drying and shortens the drying time. 2. PREVENT BRIDGE MAKING. When drying oily,sticky,abnormal shaped resin,it is easy to have the bridge making.To use the crystallized hopper dryer can prevent the bridge making effectively. 3. NUMEROUS MIXERS AVAILABLE. Different kinds of unique mixers to suit for your special needs.

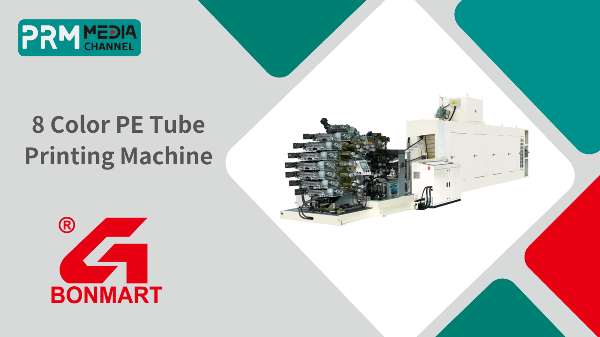

6 Cavities Automatic Injection Heading Machine | BONMART-

Double transferring rollers design. Stopless roller adjustment design. Plate wheel outer finetune mechanism Quick release ink rollers. Printing wheel clean system (200 mm dischargeable) Sleeve Printing Plate wheel pre-register mechanisim.

The Best Choice of Bag Making Machines | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Product Lines】 T-shirt Bag On Roll Making Machine Bag On Roll Making Machine T-shirt Bag Making Machine Garbage Bag & Industrial Bag Making Machine T-shirt & Bottom Sealing Bag Making Machine Side Sealing Bag Making Machine Air Cushion Bag Making Machine Stretch Rewinder Glove Making Machine 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

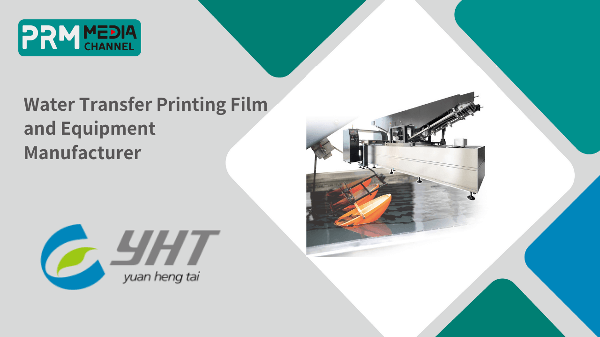

Water Transfer Printing Film and Equipment Manufacturer | YUAN HENG TAI-

Semi Automatic Hydro Dipping Machine with Lay film, Auto Spray Activator, and Production Arm. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine. The main businesses include: 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine and planning of entire plant’s equipment. While the demand for output and quality in 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine worldwide is increasing day by day, our determination for upholding the motto, "Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine products and services to higher standards.

2024 NPE Orlando Interview | ZERMA

In our first interview with Zerma, we had the pleasure of speaking to CEO, Max Paeslack about the innovative shredder they brought to NPE. Significantly, they also reveal the strategic reasons behind the decision to shift their development focus to Shanghai, China.

CHINAPLAS 2021 | PRM What to Say EP1

PRM Media Channel is here with a brand new program: PRM What to Say. More Info: https://bit.ly/2RngTZM Due to the rapid transformation in many industries because of pandemic, including plastics and rubber industry, we all realized the power of social media and video marketing. Through PRM What to Say program hosted by PRM Media Channel, we aimed to bring current issues of plastics and rubber industry on the table, and discuss these topics with experts and listen the possible solutions. Let's take a look at our first episode about CHINAPLAS 2021 and let us know your opinions and questions in the comments section. Thank you for your support!~

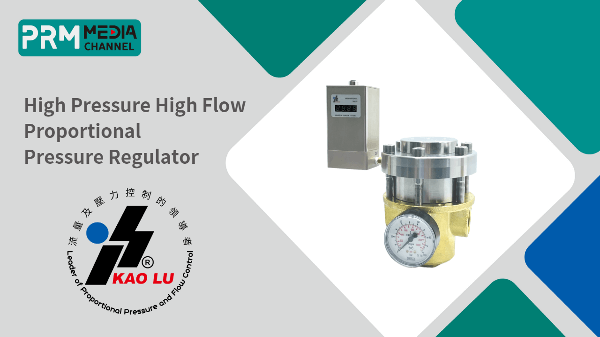

Proportional Pressure Regulator Valve | QKL-B2T+External Pressure Sensor | KAOLU

00:00 QKL-B2T Proportional Pressure Regulator Valve + External Feedback Pressure Sensor Product Introduction 00:21 QKL-B2T+External Feedback Pressure Sensor Description 00:29 Product Function: Boost Flow 00:40 Product Feature: Remotely controls cylinder pressure What is a Proportional Pressure Regulator Valve? In pneumatic world, a proportional pressure control valve is used to control downstream air pressure with an electronic signal. The input electronic signal is proportional to the span of the output pressure. For example, 0-10VDc of command signal corresponds to the output pressure span of 0 - 10 bar, with linear proportion relationship. Type of Proportional Pressure Regulator Valve? Kao Lu offers three types of electronic proportional pressure regulator: pressure ranges from vacuum -1~0bar, low pressure 0~2bar, 0~4bar, 0~8bar, medium pressure 0~16bar, 0~30bar, up to high pressure 0~70bar. In the high pressure control, the resolution can reach 0.5~0.6 bar. Proportional Pressure Regulator Valve Working Principle? Proportional Pressure Control Valve adopts a closed loop design and consists of two solenoid valves, an internal pressure sensor and an electronic control; according to an analog signal input, one solenoid valve is used to control the air intake and the other is used to control the pressure. Both valves work together to achieve a precise proportional pressure control. The proportional pressure regulator adopts two types of input signals: 0-10VDC or 4-20mA, and three types of monitor output signals: 1-5V, 0-10V or 4-20mA.

PRM Media Channel at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. In 2020 many large exhibitions in the world have been forced to cancel/postpone due to the global pandemic. Thanks to Taiwan's relatively safer environment, TAIPEI PACK successfully launched as a combination of six different Exhibitions in one. There are more than 900 domestic and international exhibitors on-site waiting to meet the visitors. Moreover, there are many online on-site exhibitions and conferences scheduled for the interest of global visitors. During the exhibition, PRM Media Channel conducted interviews with the exhibitor to gather insights into the industry. Stay tuned for the forthcoming interview videos and remember to subscribe to PRM Media Channel!~

Plastic Inflation Machine | KANG CHYAU

Plastic Inflation Machine - Twin Head HDPE Plastic Inflation Machine-Kang Chyau Specializes in Plastic Inflation Machine. Since its founding in 1988 Kang Chyau Industry has worked constantly to bring out new and innovative Plastic Inflation Machine products and offer customers a wide range of choices. After more than a decade of work our products are now sold in 62 countries around the globe, a true measure of our success in the Plastic Inflation Machine market.

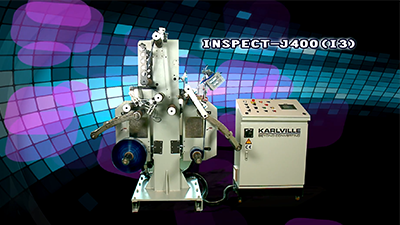

Inspection Machine | WEBCONTROL

Webcontrol Machinery Corp.- Manufacturer of inspection machine and more. More information about inspection machine: 1.Inspection Rewinding Machine- INSPECT-J300 2.Doctoring Rewinder Machine- INSPECT-H300/H400/H500 Webcontrol Machinery Corp has been specializing in manufacture of inspection machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our inspection machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast inspection machine service ensure our worldwide customers must be satisfied.

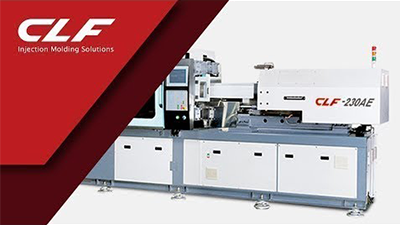

Multi-Circuit Electric Screw Drive Injection Molding Machine | CLF

Product Name: Multi-Circuit Electric Screw Drive Injection Molding Machine - CLF CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.

All Electric Molding Machine | CLF

All Electric Injection Molding Machine Features: ⚫Electricity Regeneration Circuit Electricity Saved by 15% ⚫Employs German Siemens control and servo motors for excellent performance and high accuracy. ⚫High performance injection unit that enhances the exceptional features of servo control.High speed,stability and accuracy are guaranteed. ⚫In-house software development capability combined with technical support from Siemens. ⚫Standardized hardware design simplifies the maintenance works and reduces the spare parts stock. ⚫Simultaneous control on multi-axes shortens molding cycle time dramatically. ⚫Overall super rigid structure minimizes running vibration. ⚫Exclusive energy-regeneration function not only provides electricity-saving and environmental protection, but also meets today's trend of energy-saving. ⚫Ergonomics operation interface. ⚫The access level to controller management can be ranked. ⚫Rigid platen design exhibits superior parallelism. ⚫Supports remote monitoring functions.

Interleaved Draw Tape Bag On Roll Converting System ft. Labeling Device | LUNGMENG

【Feature】 High-speed servo-driven system Special sealing system, keeping the production speed steady regardless of the film thickness and length Convenient sealing knife system, with easy changeovers of sealing knives, making production more flexible Unique perforating knife system for various film materials Intellectual rotary interleaved winder with the 2-in-1 system applicable to bags on roll and interleaved bags User friendly touch screen control system Reliable & multi-functional system, capable of producing star sealed bags, wave type bags, table covers and many more through modular system changes 【Company Introduction】 Lung Meng Machinery also known as Dragon Plastic Machinery was established in 1976 as a professional plastics converting machinery manufacturer. In 1983 Dragon Plastic developed “All In Line System”, which allows blown film extruders, printers and bag machines to work together in-line. Lung Meng Machinery's wide range of innovative machines are the very solution to exceed customer's expectation at a satisfactory price. After 46 years of continuous research and development, Dragon Plastic has become the only company that can integrate all three kinds of machines together in an in-line process.