Hydraulic Slitter and Cutting Machine | Yicheen

Hydraulic Slitter and Cutting Machine

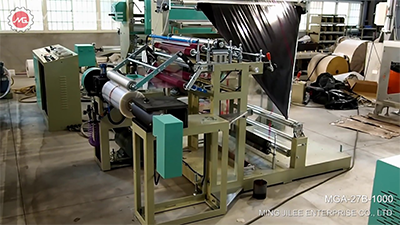

Triangle Folding Machine & 1 Color Rotogravure Printing Machine | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000, MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

Paper Bubble Mailer Making Machine, MGA 47P 1000 | MING JILEE

Paper Bubble Mailer Making Machine, MGA-47P-1000 Learn More:https://www.mingjilee.com/tw/product/... MING JILEE: PP Extrusion Line and Bag Converting Machine Since 1987 Made In Taiwan, Best Quality and Global Support Website: https://www.mingjilee.com/ E-mail: [email protected] Whatsapp: +886 934 081 955 Complete Address: No.76-8, Ming-Ho, Ming-Ho Vil., Shan-Shang Dist., Tainan City, 74342, Taiwan

2022 Intelligent Asia - Automation Intelligence and Robot | PRM Exhibition Tour

Let's PRM take you to the on-site through our online touring video!! In the video, you will be amazed how automation intelligence and robots applied in machinery to improve the efficiency and production. 2022 Intelligent Asia has 9 major manufacturing sectors that includes Automation, Robots, Logistics, Cold Chain, 3D Printing, Molds & Dies, Laser, Fluid Power, and Smart Machinery.

SIAF 2021 Guangzhou Exhibition Opens Door | PRM-TAIWAN

【 PRM-TAIWAN on SIAF Guangzhou 2021 Exhibition 】 Info: Great news for PRM-TAIWAN, Taiwanese Suppliers, and all the buyers who have put their trust in us! Despite COVID-19, we are glad to announce that thanks to our branch office in China, PRM has come back to the international exhibition ground to do what we do best - Provide professional services to international buyers! PRM-TAIWAN Plastics and Rubber B2B Platform: https://bit.ly/377P7Vv To keep updated about the latest news of the Plastics and Rubber Industry, please follow us on our Social Media Channels: PRM-TAIWAN Facebook: https://www.facebook.com/PRMTAIWAN PRM-TAIWAN LinkedIn page: https://www.linkedin.com/company/prm-taiwan/

Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

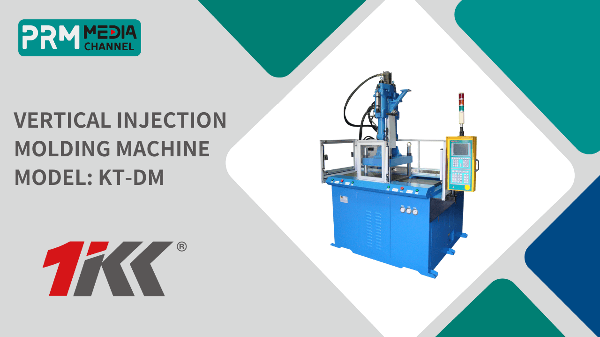

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Aluminum Foil Printing Techniques | WORLDLY

Have you ever wondered how essential it is for manufacturers and consumers to have the right packaging or sealing material on a decomposable product like medicine, snacks/drinks, or any other related product? By interviewing Klive from WORLDY, we have been explaining what kind of technical strengths Worldly has and they are capable of manufacturing and designing customization machines according to client's demand. Moreover, You will obtain the knowledge of the difference between plastic and aluminum foil to understand the applications of each materials.

Twin Screw PVC Pelletizing Line | TWIN SCREW

We are a pioneer of twin screw extruder. Description: TWIN SCREW EXTRUDER ⚫With two parallel counter-rotating screws for the palletizing. ⚫Reduction and torque-distribution unit with hardened, ground shafts and gear. ⚫Long service life for the processing units due to lower specific drive energy. ⚫Increased process reliability due to modern control technology. ⚫Easy maintenance and service. DIE FACE CUTTING ⚫Hinge flange type. ⚫High speed rotation of the knives. ⚫Continuous production of granulate. VIBRATION COOLER ⚫Up & Down two vibrating bed. SILO TANK ⚫Stainless steel. Our Service: Technology innovation, perfect service, and internationalization are always our core values, with this mission we have become the pioneer of twin screw extrusion in the global market and a reliable partner of our customers. TwinScrew will never stop progressing in the field of PVC extrusion and twin screw extrusion; we will no doubt lead the twin screw technology into an ultimate and great attainment.

K 2022 ON-SITE TOUR | PRM

Can't attend K 2022 in person? PRM will show you the most interesting exhibition highlights on【K SHOW 2022 ON-SITE TOUR】 Taiwanese manufacturers are gathering at K 2022 and showcasing their new technique of plastic & rubber machinery. You can also feel the good vibe from the show. 【Video Outline】 0:00 Introduction 0:16 CHAO WEI PLASTIC MACHINERY | Plastic Converting Machines 0:37 YE I MACHINERY | Plastic Recycling & Material Processing Machinery 1:36 HO HSING PRECISION INDUSTRY | Parts and Components 2:06 HUARONG GROUP | Injection Molding Machines 2:50 SUNKIST CHEMICAL MACHINERY | Thermoforming Machines 3:17 MING JILEE ENTERPRISE| Extruders & Extrusion Lines 3:41 QUEEN’S MACHINERY | Extruders & Extrusion Lines 3:52 CHI CHANG MACHINERY | Extruders & Extrusion Lines 4:17 HSIN LONG | Molds & Dies 4:38 FORMAX | Auxiliary Equipment and Integrated Automation 4:46 YEN SHENG MACHINERY | Extruders & Extrusion Lines 5:01 BOTHEVEN MACHINERY | Auxiliary Equipment and Integrated Automation 5:20 GENIUS | Plastic Recycling & Material Processing Machinery 5:40 JUMBO STEEL | Extruders & Extrusion Lines 6:10 WORLDLY INDUSTRIAL | Printing Machinery 7:00 PRM TAIWAN

2024 CHINAPLAS Interview | ChumPower

We are here with Mr. Bush and Mr. Michael from HCI Converting Equipment at the CHINAPLAS. Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries.

2023 IPF Interview | BPGMEA

It is our great honor to have the opportunity to interview Mr. Shamim Ahmed, the president of BPGMEA (Bangladesh Plastic Goods Manufacturers & Exporters Association). In the interview, Mr. Shamim shared much information about the plastic, printing and packaging industry, IPF Bangladesh is rapidly growing and gaining more exhibitors and visitors every year.

Central Drum (CI) Type Flexo Printing Machine | PRINTPLAS

The central impression drum surface precise grind and coated, without risk of pores and with the dual wall design for water cooling purpose to ensure material to be smoothly transport and precisely printed. 80mm thick cast metal plate frame provide a very steady, vibration free foundation for the printing work. Servo motors equipped for main drive / in-feed /out-feed / unwind and rewind, provide a smooth motion control for constant tension for film. Servo motors driven auto impression setting for each printing station with memory pack. Anilox sleeve and plate sleeve system is quick change side insert type. Turret type auto splicing for unwind and rewind is non-stop to change the roll. Equipped with internet accessible control system for remote diagnoses of programming and electronic components. 【Company Introduction】 Printplas Machinery Co., Ltd have been established since 2001 and specialized on the manufacturing of CI & STACK flexographic printing machine in Taiwan. With skill workers and machine R&D department, we are keeping our effort for providing precise, stable, high speed printing machine for our users.

HSIN LONG Blown Film Die Heads (Chinese Version) | CHINAPLAS 2021

PRM Media Channel is very glad to announce the great cooperation with CPRJ, the official media group of CHINAPLAS. For this great opportunity, we bring you one of our special actors in the Blown Film Die Head Industry to share with us important facts & insights into the industry, and how their expertise reflects an outstanding performance on customer service, manufacturing process, and quality field. With half a century of rich experience in manufacturing, HSIN LONG is mainly specialized in producing Blown Film Dies and related components. These components can be applied in Packaging Films, Barrier Films for food packaging, Technical Films for high-tech applications, Sealing Films, Agricultural Films, Medical Films, Shrink and Stretch Films, TPU Films, Biodegradable Plastic Bags / Green Plastic Bags, and many more. In this video, our PRM Director Alice will be carrying the interview with the General Manager Amy Lee from HSIN LONG Thread Rolling Co. In the following Ms. Amy Lee will be covering the following topics: 1. HSIN LONG's Mission 2. Market Segmentation 3. Process of Die Design 4. Impact of COVID-19 on Business activities 5. Vision and Future Development 6. Interests on CHINAPLAS 2021

Film/Bags Waste Plastic Recycling Machine - KCR-85 | KANG CHYAU

Inquiry and More Info: https://bit.ly/3hVGAvO Introducing the Film/Bags Waste Plastic Recycling Machine from one of the pioneering plastic recycling machinery and film extruder manufacturers in Taiwan, KANG CHYAU. Please click the link above for more information and/or inquiry, which will direct you to the manufacturer. For any assistance, PRM will be more than happy to assist. Contact us through our social media platforms or leave a comment below. Then we will reply and contact you asap. Machinery in the video: Film/Bags Waste Plastic Recycling Machine Model No: KCR-85 Output:80-120 kgs/hr Screw Diameter: Ø 85mm Single Dega Sification Suitable Materials: HDPE/LDPE/LLDPE

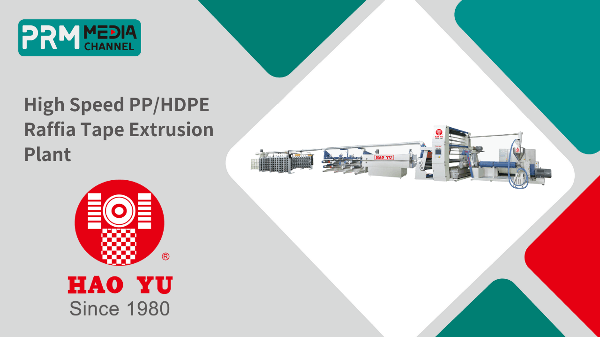

High Speed PP/HDPE Raffia Tape Extrusion Plant | Raffia Tape Extrusion Line | HAO YU

【New generation high speed PP/HDPE raffia tape extrusion plant - GV series (Green Veloz)】 / Raffia Tape Extrusion Line/Plant Features - (HY7/SP-80GV) / ⚡️Suitable for making 100% recycle PP/HDPE materials ⚡️Finish products complies with the requirement of GRS(Global Recycled Standard). ⚡️Meet the requirements of companies interested in selling their products to ESG approved companies. ⚡️Rapid color changing.

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

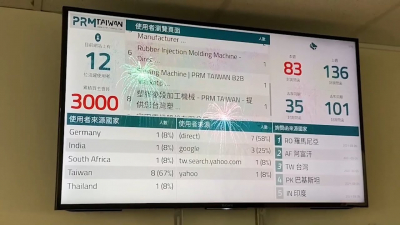

Thanks to 3000+ Members of PRM-TAIWAN B2B Platform

【Thanks to 3000+ Members of PRM-TAIWAN B2B Platform】 See Membership Benefits: https://bit.ly/3tVXnSr We would like to thank all of our supporters and our 3000 MEMBERS of PRM-TAIWAN B2B Platform for putting your trust in us and help us reach this milestone!!! We will do what we have to do, serve every customer with the most updated information and match you with the most suitable Plastics and Rubber supplier for you!

Die Cutting Machine Manufacturer | Yicheen

Yicheen High Precision Die Cutting Machine offers a variety of options, such as CCD Auto Positioning, Auto movable Stacking, etc., click the link to see more Die Cutting Machine info: ???? https://bit.ly/3qbjbtf

Shade Net Knitting Machine - EL system | FUNG CHANG

Shade Net Knitting Machine with EL system from Fung Chang Industrial Co., LTD. Slitting and Extension Machine, Raschel Knitting Machine, Knitting Unit, Winding Unit, HMI Control System, EL System. INQUIRE @ https://www.prm-taiwan.com/com/fung-chang.html?utm_source=youtube.com&utm_medium=social&utm_campaign=YouTube-Video&utm_term=pyfUJbABx3E&utm_content=fungchang

2024 CHINAPLAS Interview | ABIMAQ SINDIMAQ

It’s our great honor to interview Mr. Marcelo Zimmaro, Machinery and Accessories Sectorial Chamber for the Plastic Industry from ABIMAQ SINDIMAQ Brazil. In this interview, Jason asked him about ABIMAQ's services and business scope, his views on the economic situation in Latin America in recent years, and his expectations for this exhibition in China. Mr. Marcelo Zimmaro stated that their mission at the exhibition is to assist the Brazilian machinery industry in import and export activities, and they hope to find more allies and friends at this exhibition. For more detailed interview content, please stay tuned for the upcoming PRM reports. PRM is committed to collaborating with global media to bring more information about the world's plastics and rubber industry to everyone.

Eksim x PRM: Bridging Taiwan and Turkey in the Plastics Industry

Join us at PlastEurasia Istanbul 2024 as we interview Eksim, a prominent agent representing renowned Taiwanese brands like FKI, CLF, and LYM. Discover Eksim’s insights into the Turkish market and their strategies for building long-lasting, mutually beneficial relationships with Taiwanese manufacturers. Don’t miss this exclusive look into how Taiwan’s expertise supports Turkey’s growing demand for advanced plastic and rubber machinery!

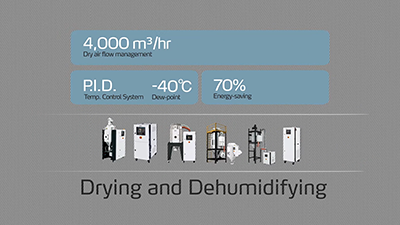

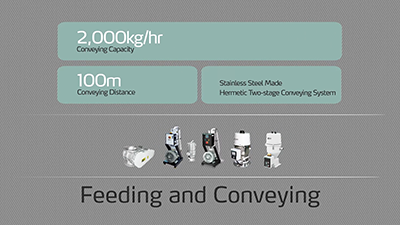

Plastic Dryer, Hopper Loader, Gravimatric Blender | SHI NI

Plastic Dryer, Hopper Loader, Gravimatric Blender - Products Overview -Shini Specializes in plastic dryer and hopper dryer. SHINI PLASTICS TECHNOLOGIES, INC. products including hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chillers, sprue picker, side entry robot,gantry robot and more. The Shini Group, Originate from Taipei, Taiwan since 1969. Five manufacturing bases and one corporate technologies center around the world. World class manufacturer of plastics auxiliary equipment. For 41 years, Shini people adhered to the management principle of Focusing on Particular Business, Pursuing to be the World Leader which created new era and achieved many progresses. Shini Group has now become a world-class manufacture of plastic dryer, hopper dryer, hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chiller, sprue picker, side entry robot, gantry robot.

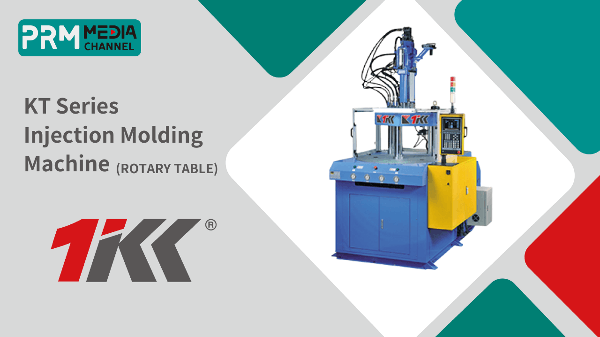

KT Series Injection Molding Machine (ROTARY TABLE) | TAIWAN KINKI

KT Series Injection Molding Machine Vertical mold clamping and injection, small footprint and high degree of precision. This machine is ideal for injection of medium and small products with inclusions. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for production of thin items. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. This machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Bag on Roll Making Machine-Draw tape Garbage Bag|Plas Alliance Ltd.

Are you looking for plastics and rubber suppliers for machinery, molds, raw materials, auxiliaries, and so on? Here is PRM-TAIWAN B2B Platform only one click away. Visit our website now and search for your Taiwanese suppliers. Learn More : • Bag on Roll Making Machine|Draw tape G... ------------------------------------ Draw tape garbage bags are advanced type of garbage bags which has strong tensile strength and puncture resistance, and controlled elongation for volume. The draw tape can be pulled and knotted for secure closure. Bag on roll are good and compact for transportation and end use for household consumers. - Bag making application - Draw tape garbage bag on roll - Folded draw tape garbage bag

Plastic Dryer, Hopper Loader, Gravimatric Blender | SHINI

Plastic Dryer, Hopper Loader, Gravimatric Blender - Products Overview -Shini Specializes in plastic dryer and hopper dryer. SHINI PLASTICS TECHNOLOGIES, INC. products including hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chillers, sprue picker, side entry robot,gantry robot and more. The Shini Group, Originate from Taipei, Taiwan since 1969. Five manufacturing bases and one corporate technologies center around the world. World class manufacturer of plastics auxiliary equipment. For 41 years, Shini people adhered to the management principle of Focusing on Particular Business, Pursuing to be the World Leader which created new era and achieved many progresses. Shini Group has now become a world-class manufacture of plastic dryer, hopper dryer, hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chiller, sprue picker, side entry robot, gantry robot.

Current Situation in Indian Extrusion Market | CCM India Interview

At the end of 2020, we had an online interview with Mr. Prashant Tanna from CCM India(Chichang Machinery India). At the interview, we have discussed various topics related to the plastics and rubber industry. Mr. Tanna sincerely replied to our questions and shared a deep insight especially about the plastics extrusion machinery market in India. We are grateful for the insight that we gathered from Mr. Tanna about the current situation of the Indian market, travel restrictions, benefits of having an agent in the local market, and so on. Let's watch the interview video together and leave your comment at the comment section!

Side Entrance Two Stages System | GEOR DING

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more. We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.

Solventless Lamination Machine-LMC-SF1300 | WEBCONTROL

Solventless Laminating-Solventlless Laminator-LMC-SF1300| WEBCONTROL Webcontrol Machinery Corp has been specializing in manufacture of Solventless Laminating since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Laminating with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Laminating service ensure our worldwide customers must be satisfied.

U Liner Bag Making Machine SHCG-75U | SING SIANG

SING SIANG MACHINERY CO., LTD

PP Woven Automatic Cutting-Sewing (Conversion) Line (CS-series) | BOTHEVEN

*Accurate bag length control by Servo Motor *Gripper bag transfer system, most advanced design *Maximum output 50 bag/min *Optional devise such as Gusset, Powder Brake, Easy Open function, Punch system, Liner Insert, Bottom Wrap *Union Special Sewing machine customized model available For more information, visit http://www.botheven.com.tw

Inspection Rewinding Machine| WEBCONTROL

Inspection Rewinding Machine-Inspection Machine-I1-Inspect J300-WEBCONTROL Webcontrol Machinery Corp has been specializing in manufacture of Inspection Rewinding Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Inspection Rewinding Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Inspection Rewinding Machine service ensure our worldwide customers must be satisfied.

HDPE Drum Plastic Recycling Machine ft. Chemical Drum Pelletizing System | GENIUS

Compacting & feeding The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor's temperature. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients' needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. 【Company Introduction】 Genius Machinery Co., Ltd. specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipments. Since its establishment, Genius Machinery Co., Ltd. has provided industries with plastic washing lines, plastic recycling machines, pelletizers, plastic squeeze dryers, crushers, shredders, and other complete series of manufacture line for one-stop services.

CHINAPLAS 2021 | PRM What to Say EP1

PRM Media Channel is here with a brand new program: PRM What to Say. More Info: https://bit.ly/2RngTZM Due to the rapid transformation in many industries because of pandemic, including plastics and rubber industry, we all realized the power of social media and video marketing. Through PRM What to Say program hosted by PRM Media Channel, we aimed to bring current issues of plastics and rubber industry on the table, and discuss these topics with experts and listen the possible solutions. Let's take a look at our first episode about CHINAPLAS 2021 and let us know your opinions and questions in the comments section. Thank you for your support!~

All-Electric Injection Molding Machine | TAIWAN KINKI

TAIWAN KINKI(TKC) is pioneer of Vertical Injection Molding Machines for Auto Industry, we were the first in the world to design and manufacture the 1st all-electric vertical injection molding machine for Taiwan and China. TKC works with a wide range of plastic injection materials and molded parts. 【All-Electric Vertical Injection Molding Machine Features】 Low Noise:All process-relevant movements (injection, mold open/close) are executed via electric motors, resulting in quieter and less noisy operation. High Efficacy:The electric unit is digitally controlled so that the mechanical operation is highly repeatable and precise, and the electrical drive enables the parallel movement of the machine, so the process is faster and more efficient. Save Water:Fewer components and oil need to be preheated than hydraulic injection machines, thus saving on cooling water usage. Power Green Energy:No hydraulic system is used, and energy is only used during machine movement, so it can save more energy and achieve power green energy.

Cutter Compactor Plastic Recycling Machine - KRIEGER Series | GENIUS

Machinery in the Video: GENIUS KRIEGER Series - KR-125 Cutter Compactor Recycling Machine [VIDEO HIGHLIGHTS] 0:00 Plastic Recycling Machine - KR-125 0:28 Belt Conveyor 0:41 Cutter Compactor 1:00 Main Extruder 1:11 User-Friendly Control Panel 1:26 Dual-Piston Filter 1:36 Die-Face Cutting Pelletizing [KEY FEATURES ] Applicable Materials: PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS, etc. Especially for plastic films, foam, woven and non-woven fabric, raffia, washed & squeezed films, flakes, edge-trimmed, and cutting-edge materials. High torque precision gearbox. Low noise and steady operation. Die-face pelletizing is expected to reduce manpower costs. The screw is specially designed for recycled materials based on their characteristics. The unique design ensures full degassing in operation. SAVE cost, energy, and time. The single extruder is suitable for clean materials such as injection leftovers and production waste. [COST SAVING] Saves energy cost up to 20% Reduces labor cost as only 1~2 operators are needed to operate the whole plant. [SUPERIOR FEATURES] /Compacting & feeding/ The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processing. Increase the highest throughputs for more productivity. /Multiple Cooling/ Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. /Flexible Customization/ GENIUS recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs, presenting a smart and reliable plant.