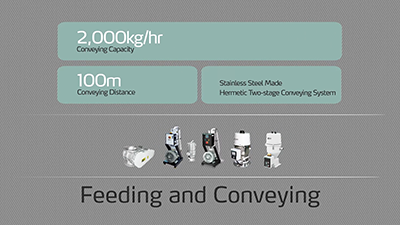

Plastic Dryer, Hopper Loader, Gravimatric Blender | SHINI

Plastic Dryer, Hopper Loader, Gravimatric Blender - Products Overview -Shini Specializes in plastic dryer and hopper dryer. SHINI PLASTICS TECHNOLOGIES, INC. products including hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chillers, sprue picker, side entry robot,gantry robot and more. The Shini Group, Originate from Taipei, Taiwan since 1969. Five manufacturing bases and one corporate technologies center around the world. World class manufacturer of plastics auxiliary equipment. For 41 years, Shini people adhered to the management principle of Focusing on Particular Business, Pursuing to be the World Leader which created new era and achieved many progresses. Shini Group has now become a world-class manufacture of plastic dryer, hopper dryer, hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chiller, sprue picker, side entry robot, gantry robot.

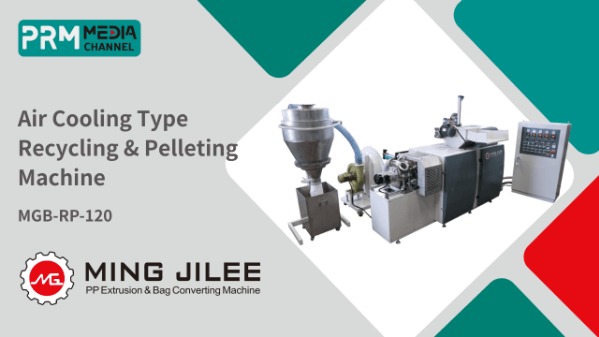

Air Cooling LD/HDPE Recycling Machine, MGB-RP-120 - MING JILEE

Air Cooling LD/HDPE Recycling machine is designs for re-pelletizing PE plastic waste material / t shirt bag die cut wasteThe material can be PE blown film waste, T shirt bag handle die cut waste, etc... Air Cooling Type Plastic Recycling Machine is equipped the power save, the SCR power regulator control. The real power consumption is around 15~20 kg. 1. Machine Specification: (1) Machine dimension a. Main machine : 2,770 (L) × 2,530 (W) × 2,060 (H) mm b. control box : 920 (L) × 420 (W) × 1,660 (H) mm (2) Machine weight : 2,430 kg (3) Power preparation : 45 kg (4) Power consumption : 20 kw 2. Machine Performance: (1) Applicable resin : LDPE / LLDPE / HDPE Waste Film (2) Output a. LD/LLD PE : 50 - 60 kg/hr b. HD/ PE : 40 - 50 kg/hr Air Cooling LD/HDPE Recycling Machine Features: (1) SCR power regular for saving power (2) Rotating die cutting head to get good quality of cutting shape (3) Less space required (4) Extra Cooling fan to cool down the PE material. Air Cooling Type Plastic Recycling Machine Further information: https://www.mingjilee.com/en/product/...

Current Situation in Indian Extrusion Market | CCM India Interview

At the end of 2020, we had an online interview with Mr. Prashant Tanna from CCM India(Chichang Machinery India). At the interview, we have discussed various topics related to the plastics and rubber industry. Mr. Tanna sincerely replied to our questions and shared a deep insight especially about the plastics extrusion machinery market in India. We are grateful for the insight that we gathered from Mr. Tanna about the current situation of the Indian market, travel restrictions, benefits of having an agent in the local market, and so on. Let's watch the interview video together and leave your comment at the comment section!

Label Converting and Finishing System | YICHEEN

Machinery in the Video: Label Converting and Finishing System from YICHEEN Features: * Running operated by full rotary die cut method or intermittent die cut method. * Die is easy in change, save a lot of time in die mold adjustment. * Micro adjustable for the depth of die, able to dotted line cut/full cut/kiss cut procession. * Servo driver and HMI control system, easy in operation, to upgrade the speed and precision control. * Sensor detector and alert for broken material to reduce material lost. * Optional module for satisfying customized demands. * Optional Mechanism: EPC, Laminating, Die Cutting (Front & Back Die Cut), Liner Razor, Varnishing, Slitting/Cutting Sheet * Application: IML(in mold label), Self-adhesive Label, Sticker, Foam, IPO, Single/Double sided adhesive, Post-press finishing material, and so on.

TAIPEIPACK 2023 On-site Tour| PRM-TAIWAN

TAIPEIPACK 2023 exhibition tour is coming! Follow Daniel to learn about Taiwanese packaging manufacturers And the first-hand industry information!

Quick Die Change | FORWELL

Quick Die Change - Quick Die Change System-qdcs-en-Forwell Features : • Decreased die change time • Designed for hydraulic and pneumatic presses • Increased efficiency • Reduced labor costs • Safer operations System Introduction : Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management. Quick Die Change Systems are becoming a standard for large manufacturers as they not only increase production efficiency, but also improve the overall working environment. The Automatic Die Change System can be built specifically for your machining requirements and will drastically reduce machine idle time during die changes, boosting your competitiveness. There are also a number of indirect benefits of installing a Quick Die Change System for your hydraulic and mechanical type press machines. Firstly, automated operations reduce labor expenses, but also reduce workshop accidents and the physical stresses on operators, making them more productive. Secondly, all dies can be changed without any modification allowing for the use of standardized die and press equipment, saving costs. Lastly, multiple presses can share a single Quick Die Change System, further economizing on costs and resulting in higher efficiency and productivity.

User Feedback from Azin Polymer | K 2022

It was an honor to interview Mr. Arash Alivirdi, a sales manager form Azin Polymer, at K 2022. He has been using PRM-TAIWAN for ten years. Let's listen his experience in using PRM-TAIWAN as a major platform for seeking machinery suppliers.

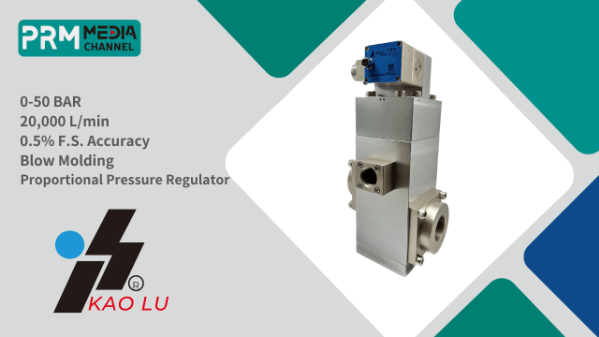

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | 高鹿兴业

产品叙述 QKL-B1T/B3:在 0–8 bar 可调范围内可用 QKL-B1S / B3H:可调范围为 0–30 bar。可定制压力范围,流量高达 3500 L/min QKL-B4H:最高可达 70 bar 除了这些产品类型外,也可以依据您的需求订制,例如:当您想要填充大型密闭容器时提高流速,或您需要随时与外部压力传感器配对使用。 想了解产品相关操作和应用,欢迎参阅我们的 Youtube频道。 压力控制器 压力控制器又称电空比例阀。几乎所有气动和液压系统中都有压力控制阀,它们有助于实现多种功能,并让系统压力保持在所需数值设定压力。不同类型的压力控制阀包括:溢流阀、减压阀、顺序阀、平衡阀、安全阀和卸载阀。除了打开减压阀外,大多数的阀门通常都是关闭的,以产生所需的压力控制。其中一个例外是外部先导卸荷阀,它依赖于外部信号进行驱动,该信号通常来自比例压力调节器或数位压力控制器。在某些应用中,例如:呼吸机和麻醉机,流量必须始终保持一致,这就是控制阀如此重要的原因。 数位压力控制器也称为电动气动调节器,它是一种可以数位控制的气动压力调节器。高鹿提供 0-10VDC、4-20mA、RS485 modbus 命令信号方式。以我们的产品 QKL-B3H 为例,假设可调压力范围为 0-30 bar(或0-435 psi)、输入信号为 2VDC、输出压力为 6 bar(87 psi)、输入 8VDC 信号、输出压力为 24 bar(348 psi) 压力控制器种类 压力控制器又称电空转换器、电空比例阀或电气比例阀。因应市场需求,高鹿的压力控制器范围可从真空到高压(-1 ~70 bar,一般市面上看到的同性质产品约30bar),除了具有高分辨率(0.5~0.6 bar 可移动量),更有快速响应时间、交期快速及品质稳定等多项优势。 高鹿制造三种类型的高品质压力控制器,压力范围可分为真空 -1~0 bar、低压 0~2 bar/ 0~4 bar/ 0~8 bar、中压 0~18 bar/ 0~30 bar、高压 0~70 bar。在高压的控制上,精度可达 0.5~0.6 bar 的高分辨率。适用于细胞抽取、玻璃机械、轮胎机械、涂装设备、吹塑机械、激光雷射机械等医疗或工业应用。 我们的压力控制器采用闭回路设计,由两个电磁阀、压力传感器及电子回路控制组成。根据接收到的类比讯号输入,由一端电磁阀控制进气量,另一端电磁阀控制排气量,透过压力传感器测量,并回馈电子回路控制,以达到精确的压力比例控制。该比例阀适合随时需要精准调控压力变化和监控压力值的产业。比例阀输入信号提供 0-10VDC(电压)与 4-20mA(电流)及 RS485 ModBus 通讯选择;监控输出则有 1-5V、0-10V 及 4-20mA 的选择。 若您需要在远端压差的环境条件下使用本产品,我们所设计的另一个功能可搭配外部压力传感器,除了会自行调控达到恒压外,还能回馈参数到机台上做监控,排除压力值不准或压差造成的震荡问题。如需高流量,本公司也提供气引导流量放大气,给需要大流量的应用产业。 本产品皆符合CE认证、SGS、RoHS、ISO13485 认证。 应用案例 压力控制器适用于医疗或工业场景,例如细胞提取,玻璃机械,轮胎机械,涂层设备,吹塑机械,激光机械...等。 喷涂设备 吹气 泄漏测试 填充设备 人工心脏 激光切割 压力控制器 QA 时间 压力控制器可以运用在哪些产业? 雷射切割、塑/ 橡胶吹塑成型机、运用张力控制机台、轮胎成型机等。 压力控制器耐脏吗? 怕脏(需使用过滤后干净的空气,请安装空气过滤器。过滤精度应选5 µm以下)。 压力控制器摆放上有无限制? 安装方向无限制(但附着水滴、油及焊渣的场所环境,请采取适当的保护对策)。 【如需更多有关压力控制器的资讯,请参考产品应用案例】

Proportional Valves for Plastic & Rubber Industry | KAO LU

KAO LU ENTERPRISES CO. is an professional Taiwanese manufacturer. With experience for over 40 years, it’s one of the leaders of the proportional pressure and flow control valves. With high-quality manufacturing techniques, their distributors spread all around the world. 【Video Outline】 Company Introduction Product Application & Competitiveness Product Introduction Main Customers Application on Medical and Biotech Equipment Application on Plastic and Rubber Equipment Advantages of the Era of Industry 4.0 Contact Information

Taiwan Injection Molding Machine | CLF

Taiwan Injection Molding Machine - Chuan Lih Fa Products: plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle. Contact Information: https://www.clf.com.tw/en/contact.html

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine. The main businesses include: 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine and planning of entire plant’s equipment. While the demand for output and quality in 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine worldwide is increasing day by day, our determination for upholding the motto, "Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine products and services to higher standards.

Sheet Cutting Machine | YICHEEN

Description: Friendly interface, PLC computer touch-panel screen control system. Non-hydraulic design, no pollution, low noise, best for using in dustless room. Servo motor control feeding (for EVA sheet cutting tolerance +/-1mm). Modulating control for tension control, it keeps cutting stable. Anti-static PU roller drive for reducing scrape happened. Optional devices: Shaftless unwind stand (electrical left/right moving), EPC (Edge Position Controller), Slitter, Punching device (electrical left/right moving), Automatic stacker, Static eliminating device,