Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W | MING JILEE

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W For Further information:https://www.mingjilee.com/en/product/Wire-Impulse-Bottom-Bag-Sealing-Machine-with-Flying-Knife-Cutter.html

Sensing & Polymer Test Equipment at K 2022 | Dynisco

We are glad to have an interview with Bill Desrosiers, Vice President of Dynisco, since our last interview at K 2019. The industry has been changed a lot due to COVID said by Mr. Desrosiers. Moreover, we had a discussion of how Dynisco implemented trending topics at K 2022, such as Circular Economy, Digitalization and Environment Protection, and applied these concepts in Dynisco products.

How Machines Shape Every Shot: The Engineering of a Golf Ball

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8 Nowadays, everything has been advanced to automation and connection to the Internet. Even in the Plastic and Rubber Industry, which we might consider as the traditional industry, it has been upgraded gradually through the industry 4.0 revolution. Let’s take a quick look to understand what are Industry 4.0 and IoT, and how does the Plastic and Rubber Industry apply it. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

Rotary Table Injection Molding Machine | TAIWAN KINKI

MACHINERY IN THE VIDEO: Rotary Table Injection Molding Machine with Full Auto System from TAIWAN KINKI (TKC) [TAIWAN KINKI LINES OF BUSINESS] Production of vertical plastic injection molding machines. Design of automatic injection molding machinery. Turn-key plants for accessories and peripherals for injection machinery. Injection mold design and manufacturing. Electrodeposition, powder coating, baking enamel, and leather treatment. Agency of the vertical injection machine and Zinc alloy coating. [APPLICATIONS] Especially suitable to manufacture Automobile Parts [TAIWAN KINKI (TKC) BACKGROUND] TKC had over 40 years of experience in Vertical Injection Molding Machine manufacturing. The company offers a full series of vertical injection molding machine portfolios including Standard, Slide, and Rotary table models. TKC also offers mold design and a full auto system for customer's products.

JIT-SS |JIT T-Shirt Bag Making Line- |JANDI'S

Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, ALL IN ONE PROCESS. HDPE / LDPE / Biodegradable / Compostable Material AVAILABLE

The Best Choice of Bag Making Machines | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Product Lines】 T-shirt Bag On Roll Making Machine Bag On Roll Making Machine T-shirt Bag Making Machine Garbage Bag & Industrial Bag Making Machine T-shirt & Bottom Sealing Bag Making Machine Side Sealing Bag Making Machine Air Cushion Bag Making Machine Stretch Rewinder Glove Making Machine 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

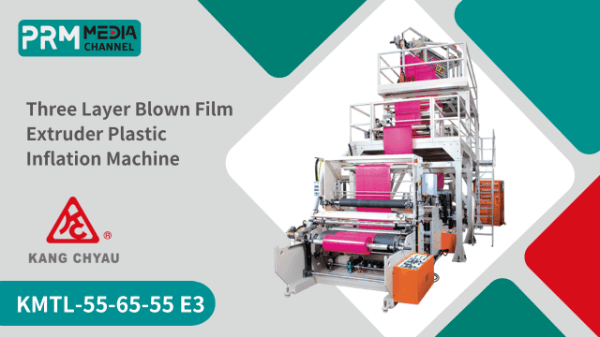

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU

Introducing three-layer blown film extruder machine, in another name called three-layer plastic film inflation machine. From one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the contact button. For any assistance, PRM will be more than happy to assist, please use CONTACT PRM button to leave a comment below. Then we will reply and contact you asap. Machinery in the video: THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE | Model No: KMTL-55-65-55 E3 Film Width: 500-1800 mm Screw Diameter: Ø 40-45-40/45-55-45/55-56-55 mm Suitable Materials: HDPE/LDPE/LLDPE/mLDPE

6 Colors High Speed Flexo Stack Printing Machine PKF-1000-6 | PRINTPLAS

6 Colors High Speed Stack Flexo Printing Machine PKF-1000-6 | PRINTPLAS The Central Impression drum surface is precisely grinded and coated, without risk of pores and with the dual wall design for water cooling purpose to ensure material to be smoothly transported and precisely printed. Machine framed with 80MM cast metal plate, provide a very steady, vibration free foundation for the printing work. High sensitive feed in and feed out tension controlling system, incorporated with synchronized motion control to ensure constant tension during printing. Super fine printing adjustment device to secure printing accuracy at each printing station. Long arch drying tunnel with strong blower to ensure drying of ink during high speed operation. Machine controlled by Japan PLC system with full color user friendly HMI. Full servo system with PLC memory module auto printing controlling system can be added to achieve a high level automation. Quick change over sleeve system can be adopted as optional.

Rubber & Silicon lnjection Molding Machines | LONG CHANG

Long Chang is manufacturing the series of Rubber & Silicon injection Molding Machines, and Heated Compression Molding Machines etc. 【Machine Series】 Silicone Injection Molding Machine Rubber Injection Molding Machine Horizontal Automatic Rubber & Silicone Injection Molding Machine Single Body / Twin Body Vacuum Oil Hydraulic Compression Molding Machine Vacuum Rubber Oil Seal Hydraulic Compression Molding Machine Single Body / Twin Body Die-Moving & Ejection Compression Molding Machine Four Columns Type Oil Hydraulic Press EVA Foam Tire / Single Body Double Color Of Automatic Oil Hydraulic Compression Molding Machine 【Company Introduction】 Long Chang Mechanical lndustrial Co., Ltd. was established in 1971, under the leadership of president Huang Chin-Huo with the idea of "always be loyal to the obligation, give more than enough thought to operate the business" and demands "making the perfection more perfect" to be the target.

Quick Mold Change System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

PRM Media Channel at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. In 2020 many large exhibitions in the world have been forced to cancel/postpone due to the global pandemic. Thanks to Taiwan's relatively safer environment, TAIPEI PACK successfully launched as a combination of six different Exhibitions in one. There are more than 900 domestic and international exhibitors on-site waiting to meet the visitors. Moreover, there are many online on-site exhibitions and conferences scheduled for the interest of global visitors. During the exhibition, PRM Media Channel conducted interviews with the exhibitor to gather insights into the industry. Stay tuned for the forthcoming interview videos and remember to subscribe to PRM Media Channel!~