Medical spiral tube extrusion machine line (double output ) | Everplast

Medical spiral tube extrusion machine line (double output ) The medical tube, made by food-grade materials, with the advantage of high transparency, good elasticity, good fluidity and corrosion resistance, suitable for medical, pharmaceutical and food production of gas and liquid delivery pipes, etc. -Contact Info: Twitter: / everplast Facebook: https://reurl.cc/r1LZb Web: https://www.everplast.com.tw/ Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

Campaign Video|EG-8002 Duplex Center Winding Slitter Rewinder|Nicely

Nicely is preparing to showcase our expertise globally. Our standout model is the EG-8002 Duplex Center Winding #slitterrewinder for #label #paper #processing. With advanced technology, superior tension control, and versatile #automation, it handles diverse #materials seamlessly. Nicely focuses on delivering tailored solutions, offering customized slitter rewinders, automation upgrades, and control system modernization. Each step of our process is carefully designed to address specific customer needs while aligning with the latest industry trends.

PA/PET Monofilament Extrusion Line (JC-MNN) | PLASCO

PLASCO's JC-MNN series of extrusion lines utilize a dual-stage drawing/single-stage heating process to produce high quality PA6, PA66, PET or PP monofilament extrusion line. 【Product Spec】 Applicable Materials: PA/PET Screw Diameter (mm): 50 / 55 / 65 / 80 Filament Diameter (mm): 0.12-1.00 / 0.12-3.50 / 0.50-3.50 Extrusion Capacity (kg/hr): 35 / 50 / 75 / 120 【Application】 Rope Toothbrush Longline monofilament Fishing line Tennis strings Fishing net 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

押出模具与周边制造商

政钰机械于 1989 年,由一群拥有操作押出模具周边产品以及相关研发经验的资深设计工程师、技师,共同组成研发设计团队,以客户需求为核心,量身订做产品,深耕业界超过30年,成为全球知名押出模具制造商之一。厂内有完整的加工设备,从设计、加工、组装以及品检,所有制程皆在本厂完成,落实良好的品质控管,获得客户一致的肯定与赞赏。

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN Introducing automatic injection molding mold change carts system from SANDSUN in Taiwan, which is a leading global customized die and mold change cart system manufacturer. Please refer to the link above to learn about SANDSUN's detailed designs on the mold cart system, including functional advantages such as Hook Type, Motor Roller Type, Real Case, and Electric Mold Trolly. SANDSUN has been providing high quality, secure and efficient injection molding machine mold change cart systems to India, South Korea, Thailand, the United States, Vietnam, Malaysia, Mexico, Brazil, Russia, and many other countries at a reasonable and affordable price for many years. Thus, SANDSUN earned a good reputation in mold change systems and die change systems around the world. Features of die/mold cart system : Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival, and positioning in the process of moving. Device for preventing mold sliding. Die / Mold Cart System co-ordinate with AGV : This video was shot at Chung Yuan Christian University in Taoyuan, Taiwan. The content is the collaboration between the automatic mold cart system and the automated guided vehicle (AGC). The combination of two high-tech devices effectively increases industrial production efficiency and achieves industry 4.0 goals. # SANDSUN Die Cart System Mold Cart System AGC Automated Guided Vehicle Fourth Industrial Revolution Industry 4.0 PRM Media Channel Hizli Kalip Degistirme Sistemleri Enjeksiyon Makinesi Kalip Degistirme

Liquid, Solid and Granule Food Packaging Machine Solutions | SAN TUNG Interview

At the last version of the TAIPEI PACK exhibition, PRM Media Channel had an interview with SAN TUNG MACHINERY. We invite you to take a look at the food packaging machine solutions and industry observation of SAN TUNG. In the video, you will find the on-site machine introduction of - Liquid Food Packaging Machine Solutions - Solid Food Packaging Machine Solutions - Granule Food Packaging Machine Solutions by the demonstration of Mr. Yao & Ms. Cathy. Moreover, Ms. Cathy is also sharing her insights into the current situations in the packaging industry, and her expectations of future cooperation with their clients.

Continuous Thermoforming Machine SL-1220A + SL-520 for Lid Production | CHULIING

【MACHINERY IN THE VIDEO】

Vacuum Molding Machine | LIN CHENG

Vacuum Molding Machine - Oil Seal Vacuum Molding Machine- LIN CHENG Specializes in Vacuum Molding Machine, Lin Cheng Technologies Co., Ltd. was established in 1978 and has a strong professional team to manufacture Vacuum Molding Machine. A series of services we can provide ranges from the purchase of machines to the design and development of molds. Our Vacuum Molding Machine products are used for electronic components, car parts, oil rings, and so on. In 1997, we were granted the ISO 9002 quality certification.

Single-stage Injection Stretch Blow Molding Machine | GOLFANG-

Golfang treasures what have been entrusted... customizing special machine with molds for each customer. Golfang specializes in the development and manufacture of " single-stage injection stretch blow molding machine". Provide customers with a whole set of production equipment which includes customized machine and mold. Strictly control the quality and reliability of all assembly parts. Do the test runs repeatedly including mold testing and material testing before delivery. Obtain the most stable molding parameters based on the molding characteristics of the plastic specified by the customer and the adjustment during the bottle production. Meet the customer’s quality and production capacity requirements. Finally, after the machine acceptance, transfer the molding technique to the equipment user and do the personnel training. The equipment ca be run in full-time production with durability, high-efficiency, and high-stability, which creates the best return on investment for the customer. It is also the first choice for producing high-end plastic packaging containers when small quantities, varieties, and high quality are required at an early development stage. The Golfang team has accumulated many years of experience in the field of plastic product: PPSU baby bottles, PC/PMMA lampshades (LED light bulbs), HIPS yogurt bottles, PP/PE/PET medicine bottles, TRITAN water bottles, PET/PETG cosmetic bottles, household product bottles, etc... exquisite packaging containers. Also cooperated with the customers in developing products for well-known brands, include Pigeon, AVENT, Nuby, Yakult, Unilever, LOREAL, AVON, SHISEIDO, Pfizer, etc. Mold development is nothing more than a solution to product market demand. In the field of injection blow molding, Golfang insists on research, design, and manufacture of exclusive molds, and never relies on others, because we know that molds are designed and developed in response to the equipment. When customers evaluate and launch new product according to the market trend, what they need is stable quality and the chance to get ahead of the game. Therefore, with Golfang’s established and mature molding technique, whether it is the mold’s durability (2 million cycles guaranteed) or the delivery time, Golfang is always the most reliable choice for the customer. The common design of mold bases and mold parts is able to save mold costs and improve competitiveness for the customers. It provides them with the most economical solution. Golfang would communicate on product sizes beforehand and suggest for minor alteration. In such a way, Golfang gains good recognition from the customers.

Accumulator Blow Moulding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. Detail Specifications : The Abl Series Blow Moulding Machines Are Particularly For Producing The Jerry Can/Drum Tank/Large Article Produtions.It Can Be Combined With Some Accessory Equipments To Increase The Efficiency And Expand The Functions, Such As: After Cooling Unit/Auto Deflashing Unit. The Die Head Can Stock The Melting Resin And Purge The Material For Blowing Formed It Designed With Two Heart Flow Chnnels.Can Make Welding Line-Free To Increase The Strength Of Production. The Tie Bar-Less Clamping Unit Is Consist Of Stiffness Structure Frame And Guiding Devices.Make Sure Deflection-Free Advantage. Also Devise With Precision Rack GgearsO of Bboth Side.Make Synchronize Moving Of Plates. The Blowpin Unit Is Designed For Production Calibrating. That Will Be Suited For Different Demand Of Customer. Accumulator Die Head Blow Moulding Machine. GEFRAN CONTROL SYSTEM -PID Temperature Control System (With High/Low Alarm) -Motor PID Feedback Control Function -300 Points Parison Control -PLC Ladder Program Edlitor -Presscription Record Memory Accumulator Die Head Blow Moulding Machine AUTO-DEFLASHING UNIT This Unit Can Be Excuted Top/Bottom/Handle Deflashing Function By Hydraulic And Pneumatic. And Then Used With Suction Device To Take Out And Turn Over The Production.

Plastic Welding Machine at K 2022 | TAI YEN

By interviewing Mr. Tony, from Tai-Yen Industrial Co., at K 2022, we have a quick understanding or their solution and product series, such as High Frequency Plastic Welding Machine and Ultrasonic Plastic Welding Machine.

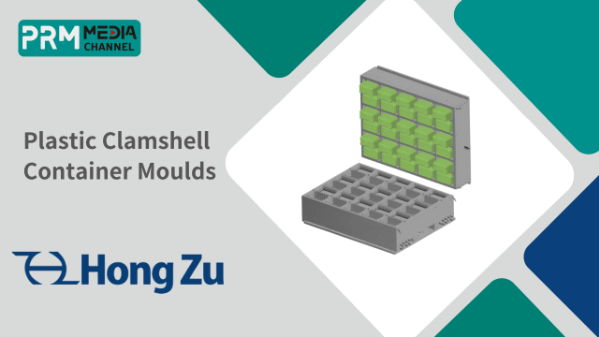

Thermoforming Machine CM 100A with Forming Mould PET Clamshell | HONG ZU

Thermoforming Machine CM 100A with Forming Mould PET Clamshell forming area with 25 cavities per mold the products are formed so perfectly. High-efficiency, high-quality thermoforming mold for customer satisfaction.