Continuous Thermoforming Machine SL-1220A + SL-520 for Lid Production | CHULIING

【MACHINERY IN THE VIDEO】

ABA Blown Film Machine (JC-ABA) | PLASCO

PLASCO's JC-ABA Series of 3-layer co-extrusion blown film lines are the ultimate economic and environmental solutions for multi-layer blown film production. 【Machine Spec】 Applicable Material: LDPE / LLDPE / MDPE / HDPE Screw Diameter (mm): "45/55", "50/55", "55/75" Film Layflat Width (mm): 800 / 1000 / 1200 Film Thickness (mm): 0.015-0.10 Extrusion Capacity (kg/hr): 100 / 160 / 250 【Application】 Express Bag Plant Bag Shopping Bag T-shirt Bag Laundry Bag Garbage Bag 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

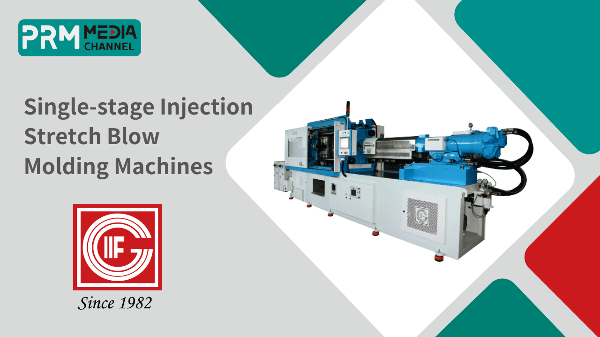

Single-stage Injection Stretch Blow Molding Machine | GOLFANG-

Golfang treasures what have been entrusted... customizing special machine with molds for each customer. Golfang specializes in the development and manufacture of " single-stage injection stretch blow molding machine". Provide customers with a whole set of production equipment which includes customized machine and mold. Strictly control the quality and reliability of all assembly parts. Do the test runs repeatedly including mold testing and material testing before delivery. Obtain the most stable molding parameters based on the molding characteristics of the plastic specified by the customer and the adjustment during the bottle production. Meet the customer’s quality and production capacity requirements. Finally, after the machine acceptance, transfer the molding technique to the equipment user and do the personnel training. The equipment ca be run in full-time production with durability, high-efficiency, and high-stability, which creates the best return on investment for the customer. It is also the first choice for producing high-end plastic packaging containers when small quantities, varieties, and high quality are required at an early development stage. The Golfang team has accumulated many years of experience in the field of plastic product: PPSU baby bottles, PC/PMMA lampshades (LED light bulbs), HIPS yogurt bottles, PP/PE/PET medicine bottles, TRITAN water bottles, PET/PETG cosmetic bottles, household product bottles, etc... exquisite packaging containers. Also cooperated with the customers in developing products for well-known brands, include Pigeon, AVENT, Nuby, Yakult, Unilever, LOREAL, AVON, SHISEIDO, Pfizer, etc. Mold development is nothing more than a solution to product market demand. In the field of injection blow molding, Golfang insists on research, design, and manufacture of exclusive molds, and never relies on others, because we know that molds are designed and developed in response to the equipment. When customers evaluate and launch new product according to the market trend, what they need is stable quality and the chance to get ahead of the game. Therefore, with Golfang’s established and mature molding technique, whether it is the mold’s durability (2 million cycles guaranteed) or the delivery time, Golfang is always the most reliable choice for the customer. The common design of mold bases and mold parts is able to save mold costs and improve competitiveness for the customers. It provides them with the most economical solution. Golfang would communicate on product sizes beforehand and suggest for minor alteration. In such a way, Golfang gains good recognition from the customers.

2024 CHINAPLAS Interview | King Plus

They are the manufacturer of blown film machines. In the past thirty-five years, Han King has relentlessly accumulated vast experience, from manufacturing mono-layer machines to two-layer, three-layer, and five-layer machines. We develop and produce our rotary die, embossing device, 360-degree oscillating haul-off, internal bubble cooling system, automatic air ring, and other blown film machine components.

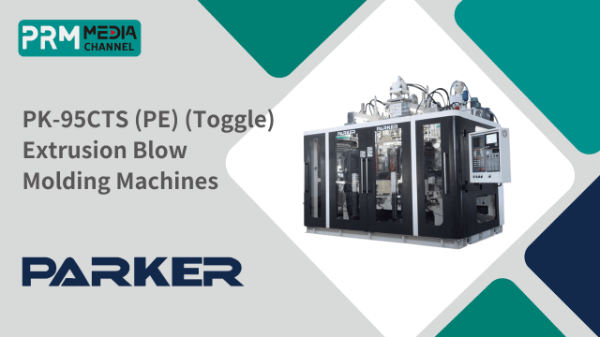

PK-95CTS (PE) (Toggle) Single Head Twin Station Blow Molding Machine | PARKER

For more info or Inquiry, please visit PARKER on PRM TAIWAN.

SUNKIST CHEMICAL MACHINERY | Interview at K 2019

We are pleased to interview Willie Huang from SUNKIST, a company from Taiwan with a great reputation for producing the machinery required for flexible and rigid polyurethane foam. This time Mr. Huang gives us a brief introduction of the company and how they are developing new machines that fulfill the new trends in the market, also making emphasis on their social responsibility with the environment. He mentions how Sunkist is facing the current challenges, such as Global warming, giving examples of how the industry is working in plastic reduction. Also, we get their new machinery introduction during K 2019, for more details please click the info card on the video or visit our B2B Platform.

5G PET Preform Turnkey | KING'S SOLUTION

5G PET Preform Turnkey - 5 Gallon PET Preform Injection Molding Machines & Whole Plant Turn-Key Solution-pet-King's Machinery. FEATURES Select from 2, 4 or 8 cavities mold specifications. Single mold, 4 cavities design. The 2 stage material feed system raises the repeatability rate, lowers the cycle time, and boosts performance. When combined with a secondary cooling system, performance can be doubled. Temperature control via TSR raises temperature accuracy and, working with the accumulator, increases injection speed. Unique economical design is twice as energy efficient as comparable commercial units. we offer a complete set of 5 gallon PET bottle manufacturing equipment: raw material dehumidification and drying system; fixed-volume color additive; quickly stabilizing PET bottle preform molding machine; 4 cavity, hot runner mold; rapid cooling robot; and bottle blowing machine. From raw material to finished product stages, this all-inclusive system promotes high productivity, low cost, and superior quality-the bottle blowing defect rate is kept to a minuscule 0.5%. When water is shortage and lack of quality sanitary sewer, therefore, water container or bottle is convenience to filling in clean water and to carry with to the public. Moreover, bottle is not only for water-use but also oil-use even other liquid-use. King's gallon-size pre-form is one of the best choices in worldwide. Not only does save 20% of shipping cost but also decrease defect of blowing rate down to less 0.5%. And the most critical point is that any color is so clear by King's latest technology and 20 years PET knowledge.

Plastic Injection Molding Innovations and Green Solutions | KING'S SOLUTION

Livestream time: November 20th at 19: 00 (GMT +8, Taipei) The Livestream that PRM Media Channel held with KING'S SOLUTION CORP. with the title of Plastic Injection Molding Innovations and Green Solutions brings you new insight into the injection molding machine industry. Remember to direct your questions in the live chat section, KING'S SOLUTION and PRM Media Channel will be replying to your questions. What are the challenges, trends, and innovations in the injection molding industry? How to sustain after-sales services during post-pandemic? What advantages LPM (Low-Pressure Molding) brings to the manufacturers compared to Epoxy Injection Molding? Do you also have similar questions like that or would like to learn more? Then we welcome you to watch the Livestream video on November 20th at 19: 00 (GMT +8, Taipei) 【VIDEO OUTLINE】 00:00 Opening 00:59 KING'S SOLUTION CORPORATION 02:00 "Green Solution, Machine Soulmate" Slogan 03:04 Why to customize the machines? 05:00 Customized Machine Series 06:00 Market Challenges and Successful Cases 10:38 5 Gallon PET Preform Injection Molding Solutions 12:35 Advantages of KING’S in 5 Gallon PET Preforms 16:16 Trends in Injection Molding Market 18:40 LPM Application Examples 23:00 LPM Method vs Epoxy Method 26:00 After Sales Services and Customer Relations 28:55 Message to Current and Potential Customers Know PRM Media Channel more on: PRM Media Channel Website: https://bit.ly/3uqdubs PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

Campaign Video|EG-8002 Duplex Center Winding Slitter Rewinder|Nicely

Nicely is preparing to showcase our expertise globally. Our standout model is the EG-8002 Duplex Center Winding #slitterrewinder for #label #paper #processing. With advanced technology, superior tension control, and versatile #automation, it handles diverse #materials seamlessly. Nicely focuses on delivering tailored solutions, offering customized slitter rewinders, automation upgrades, and control system modernization. Each step of our process is carefully designed to address specific customer needs while aligning with the latest industry trends.

2024 NPE Orlando Interview | GENOX USA

In this interview with Genox USA, we talk to Mr. O' Donnell about how Genox provides valuable machines and solutions for the plastic and metal recycling markets in America. He shares insights into the company's offerings and outlines their future plans for expansion in North America and Latin America.

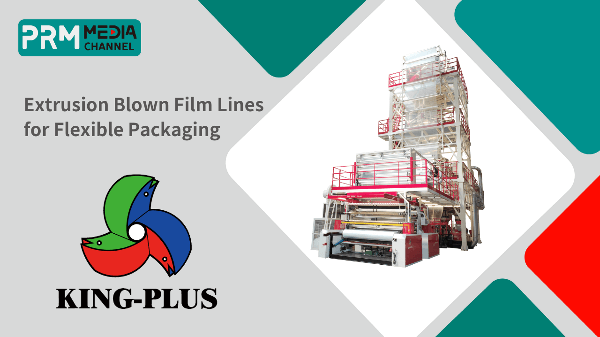

Extrusion Blown Film Lines for Flexible Packaging | KING PLUS

Three-layer blown film machine for lamination film Including: Auto air ring Gravimetric dosing system Internal bubble cooling system (IBC) In-line thickneess gauge Oscillating haul-off Back to back double winders Customized blown film machine to meet your need! Welcome to contact us!