Plastics & Rubber Machinery Videos

With PRM professional matching services, we labeled 15 Machinery Categories and more than 600 videos, for you to conveniently find a supplier that best suits your business.

全部

AUXILIARY EQUIPMENT AND INTEGRATED AUTOMATION

BLOW MOLDING MACHINES

EXTRUDERS AND EXTRUSION LINES

FINISHED/SEMI-FINISHED PRODUCTS

INJECTION MOLDING MACHINES

MOLDS AND DIES

PACKAGING MACHINERY

PARTS AND COMPONENTS

PLASTIC CONVERTING MACHINES

PLASTIC RECYCLING & MATERIAL PROCESSING MACHINERY

PRINTING MACHINERY

RAW MATERIALS & ADDITIVES

RUBBER PROCESSING MACHINERY

SHOE MAKING MACHINERY

THERMOFORMING MACHINES

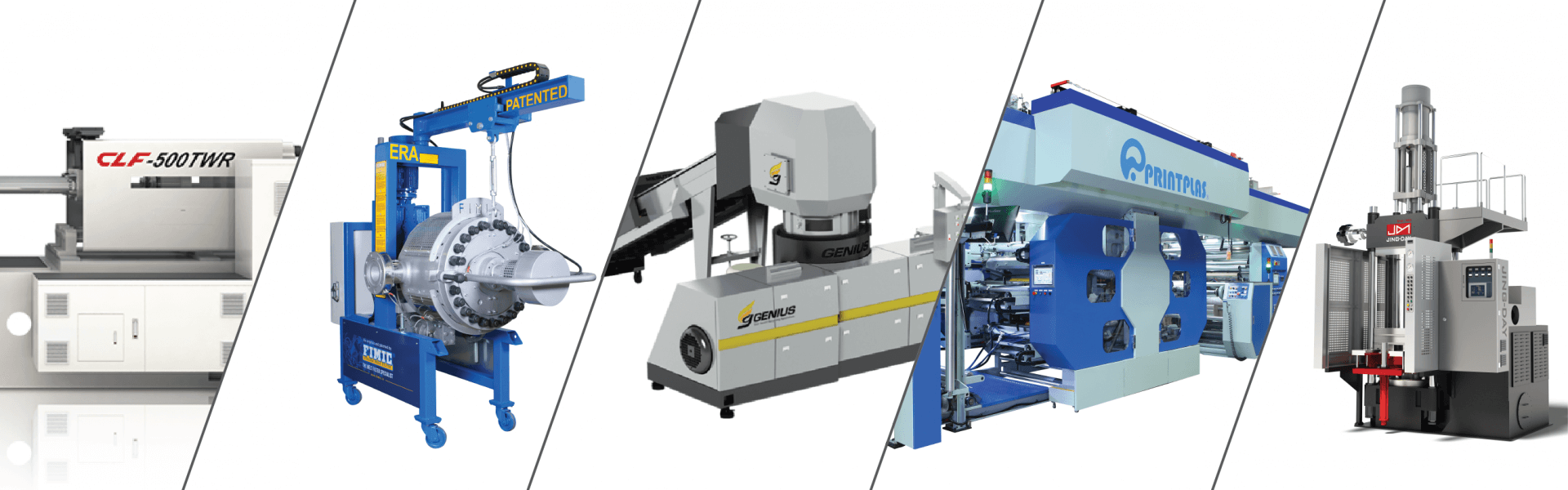

Automatic Log Roll Cutting Machine can be applied to cut rolls of various tape materials, such as double-sided tape, electrical tape, masking tape, construction tape, etc.. More product info: ???? https://bit.ly/3q8uLWw

/ Automatic Log Roll Cutting Machine Features /

Cutting running is driven by AC motor with inverter control. Fast and stable to speed up & down.

PLC control system Auto change cut size setting in the same shaft.

Precise and smooth positioning.

Multi-speed cutting rolls to improve operating efficiency and maintain high quality.

The blade has different angle changes according to different materials, reducing the number of tool changes.

/ Advantages of Yicheen /

Leading the industry in the research and development of the Die-Cutting Machine". In addition to the continuous improvement of technology, it has also developed a variety of Printing Machines, Laminating Machines, Cutting Machines, Sheet Cutting, Slitting Machines, and other equipment to provide complete plastics Processing equipment solutions.

/ links of Yicheen /

Contact us: https://bit.ly/3q8KLaK

Subscribe us: https://bit.ly/3wGjjU3

Product Info: https://bit.ly/3tU2QdK

Fully Automatic High Speed Double Lines T-Shirt Bags Making Machine with Hot Slitting & Side Gusseting Device.

Model : ST-88-G2 Machine Features: https://www.cosmo886.com.tw/en/products_i_High_Speed_T-Shirt_Bag_Making_Machine_with_hot_Slitting_and_Side_Gusseting_Unit_ST-88-G2.html

➤Contact Us COSMO MACHINERY CO., LTD. Web: https://www.cosmo886.com.tw

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W

For Further information:https://www.mingjilee.com/en/product/Wire-Impulse-Bottom-Bag-Sealing-Machine-with-Flying-Knife-Cutter.html

Model No : FK/EHB-55G-100G-55GT20SD Energy Saving Power consumption 40~50%↓ Production output 20~25%↑

ECO No hydraulic oil, no pollution, Noise level 20dB reduced.

Industry 4.0 Smart manufacturing, with SCADA system.

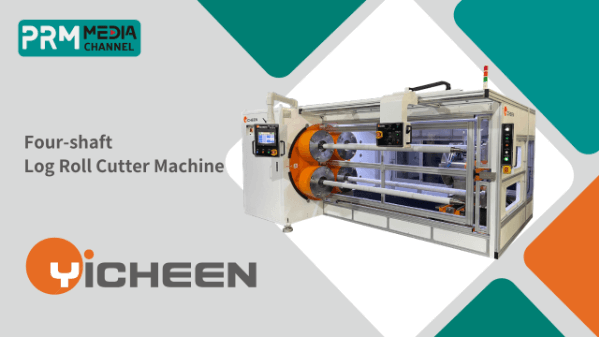

Y-Fang Automatic Rotary Sealing Machine (ET-80) is designed to provide seamless and efficient sealing for bowls and cups. This advanced machine offers a fully automated process, from product loading to precise sealing, ensuring a secure and airtight finish every time. Its compact design is ideal for businesses seeking to maximize efficiency while maintaining high standards of hygiene and product quality. With easy operation and robust construction, the ET-80 is the perfect solution for streamlined packaging in the food and beverage industry.

Application

✔️Suitable for beverages, Pudding, Jelly, Fast-food, Snacks, Various prepared foods for the microwave, Seasoned frozen food, Pickled foods, Seafood, processed agricultural products, etc. Which load into the cup and tray.

✔️Sealable material: PP, PE, PS, PET, HDPE, EPS, PSP, Aluminum foil, Paper box, etc.

✔️For smaller working spaces but higher capacity.

Y-fang Group was established in 1985, specialize in the design and manufacture of sealing machines for various industrial applications. With over years of manufacturing experience, we are able to produce a wide range of tray sealing machines with a capacity of 450 to 600 pieces per hour.

Our machines can perform a variety of different functions such as auto-dropping, piston filling, date printing, vacuuming, and gas flushing (MAP: Modified Atmosphere Packaging). Furthermore, we are also able to provide our customers with OEM, ODM, and OBM manufacturing solutions. Our products have been exported to countries over the world, including Europe, Asia, Africa, and America.

Nicely is preparing to showcase our expertise globally. Our standout model is the EG-8002 Duplex Center Winding #slitterrewinder for #label #paper #processing. With advanced technology, superior tension control, and versatile #automation, it handles diverse #materials seamlessly.

Nicely focuses on delivering tailored solutions, offering customized slitter rewinders, automation upgrades, and control system modernization. Each step of our process is carefully designed to address specific customer needs while aligning with the latest industry trends.

Thermoforming Machine CM 100A with Forming Mould PET Clamshell forming area with 25 cavities per mold the products are formed so perfectly. High-efficiency, high-quality thermoforming mold for customer satisfaction.

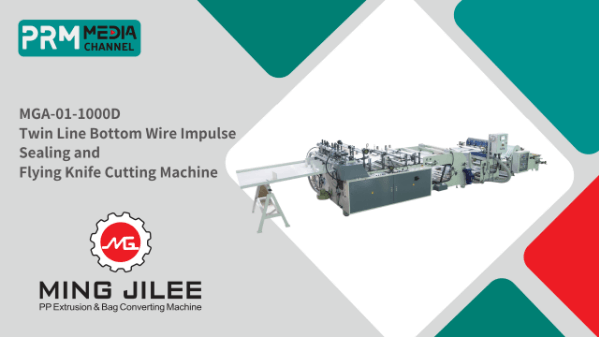

Twin lines Bottom Bag impulse sealing and flying knife cutting machine, MGA-01-1000D

PAL has decades of experience in Plastic Bag Making Machine manufacturing, and continues to develop, manufacture, and sell to all over the world, and even participates in exhibitions around the world.

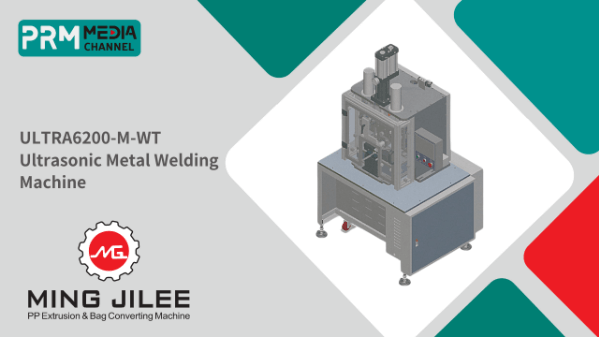

ULTRA6200-M-WT

Ultrasonic Metal Welding Machine

Our raschel knitting machines also knows as green net manufacturing machine is a high-quality, versatile machine that can be used to create a variety of nets for agricultural, construction, and sports use. With its rugged, distortion-proof welded steel construction and main drive by special cams, which are dynamically balanced and run in oil in the machine bed, our machine is built to last.

Main Applications

Our raschel knitting machines can be used to create a variety of nets for agricultural, construction, and sports use, such as:

Shade net: Our shade nets can be used to protect crops from the sun's harmful rays.

Greenhouse net: Our greenhouse nets can be used to create a controlled environment for growing plants.

Anti-birds & wind protection net: Our anti-birds and wind protection nets can be used to protect crops from birds and wind damage.

Building safety net: Our building safety nets can be used to protect workers from falls.

Scaffold net: Our scaffold nets can be used to protect workers from falls while working on scaffolds.

Industrial net: Our industrial nets can be used for a variety of purposes, such as protecting equipment and materials.

Football gate net: Our football gate nets can be used to protect players from injuries.

Packing net: Our packing nets can be used to pack a variety of products, such as potatoes, onions, and fruits.

Trusted shading net machine manufacturer

Provide the most reliable and most affordable shading Net Machine, Wei Meng is based on the rich manufacturing experience of raschel knitting machine, developed the highest quality green net manufacturing machine, and manufactured the shading Net Machine with the best shading effect. Wei Meng is your most trusted green net manufacturing machine manufacturer and supplier.

Green net manufacturing machine at affordable price

The green net manufacturing machine produced by Wei Meng not only produce excellent quality sunshade nets, but also have a wide range of applicable plastic materials. Most importantly, we provide high-quality shade Net Machine to China, India, Turkey, Manufacturers in Poland, Russia, and the Middle East at the most affordable low price.