近期更新 立即订阅

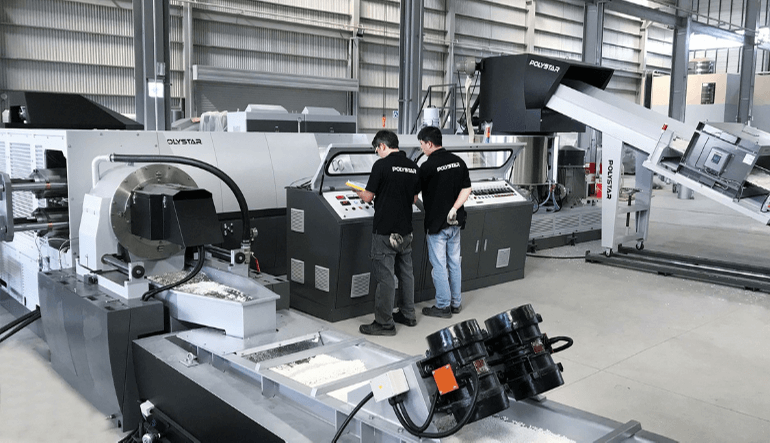

Cost-Saving and Friendly Operation POLYSTAR Plastic Recycling Machines

Plastic pelletizers are not only used by recyclers anymore as more producers now adopt circular economy standards in their factories. Having a recycling machine in your production facility not only helps the environment but can also help you cut costs. Before choosing a recycling machine you must consider some important factors, that you will find in this article.

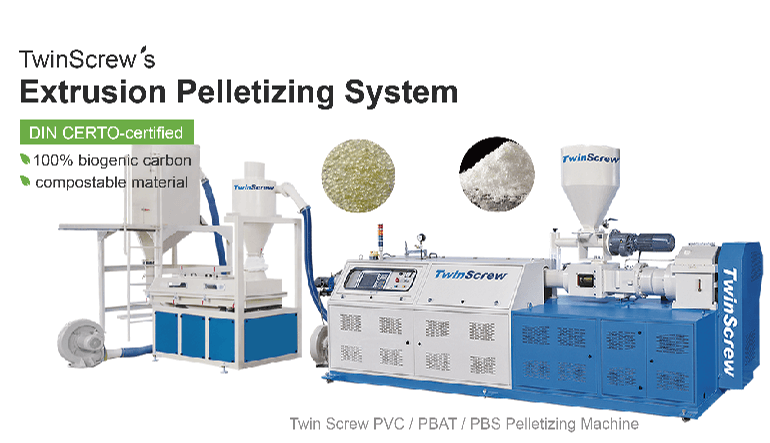

JANDI’S - The Differences in the Nature of PE & Biodegradable Material (PLA/PBAT Based)

According to the material supplier, bio-degradable material cannot be recycled easily. But, if not trying to recycle, the disposal of the waste & die-cut from bio-degradable material will become big additional expenses. Even if you may recycle the bio-degradable material, the time, space and workman ship required for the collection of the waste, will already create additional costs. Because of the above reasons, JANDI’S JIT is the best solution for the production of PLA/PBAT Bio-Degradable T-shirt bags.

Which Molding Machine is Best for Your Project?

The process to make rubber and silicone products is including materials preparation, mastication, mixing, preformer, cutting, calendaring, vulcanization and machining step. Each step needs specific equipment and technology to complete.TungYu provide machines with the best control on temperature and pressure which is the critical parameter in curing process.

Esleeve: Revolutionizing Shrink Sleeve Labeling with Cutting-Edge Solutions

In the fast-paced world of product packaging, staying ahead of the competition requires innovative solutions. Eversleeve Enterprise Co., Ltd. (Esleeve) is a leading global supplier of auto shrink sleeve labeling machines and accessories, dedicated to delivering state-of-the-art technology and exceptional service.

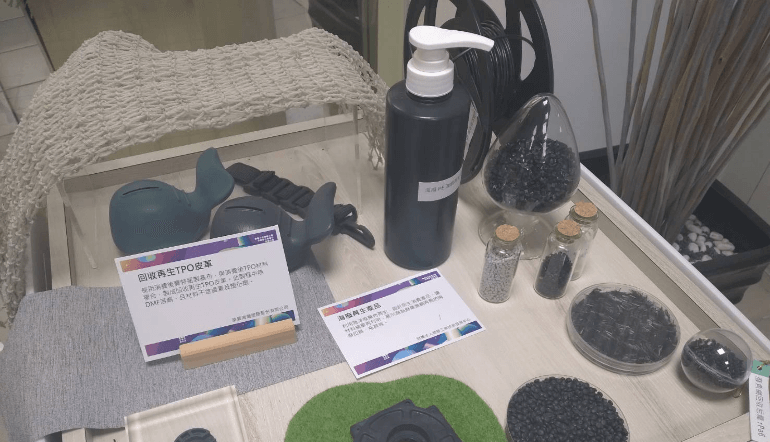

落實永續循環:塑膠中心打造低碳新包材

在氣候變遷、地球暖化的壓力下,低碳淨零永續已是全球共識與重要積極作為,歐盟與美國等先進國家先後發佈一次性塑膠製品限用、回收政策與淨零碳排之相關規範,如歐盟與美國直接要求2025年底前,所有包裝材料必須含有25%的回收料。此外,塑橡膠廠商亦不斷探尋具高值潛力的低碳永續材料,以及回收塑料再生的開發,打造完整上中下游的綠色經濟產業鏈。

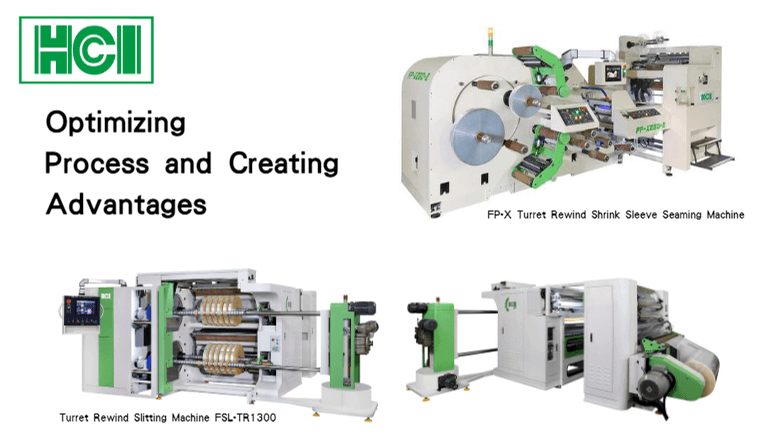

HCI: Optimizing Process and Creating Advantages

HCI, a solution provider of converting equipment in the flexible packaging supply chain, assisting customers in streamlining processes to convert products specification with upstream and downstream processing. HCI's core value is based on its 40 years of experience, which allows us to undertake customized equipment design and manufacturing. Acts as a "Box Cutter" for precise cutting (converting), assisting customers to overcome the bottle-neck encountered in its production and entering the blue ocean market competition together.

Unlocking the Process: How to Establish Your Own Plastic Film Recycling Washing Line/Plant in 5 Steps?

In the last decade, Plastic Film Recycling Washing Line has become a popular option for companies looking to reduce their carbon footprint and increase their sustainability. The process of building your own plastic film recycling washing line can seem daunting, but it doesn't have to be. With careful consideration of various factors, you can unlock the process to establish your own plastic film recycling washing line/plant.

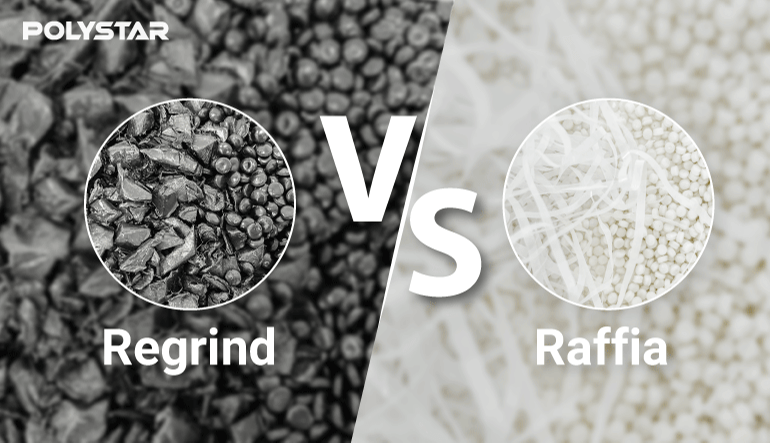

Choosing the Right Recycling Machine: Hard Plastic Regrind VS. PP Raffia/Woven Recycling

There are plenty of plastic material types that we use in daily life as well as in many different industries. In addition to different polymer types of them, these plastic materials also come in different shapes, sizes, textures, and levels of stiffness. These are the main points that plastic recycling machines should specialize to process certain types of plastics more efficiently while still capable to process various types of other plastic materials.

Plastpol 2023.05.23~05.26 | Yuan HengTai

We are so excited to be participation in the 27th International Fair of Plastic and Rubber Processing- Plastpol. This year, we will be presenting more options and ideas of design for the plastic industry.

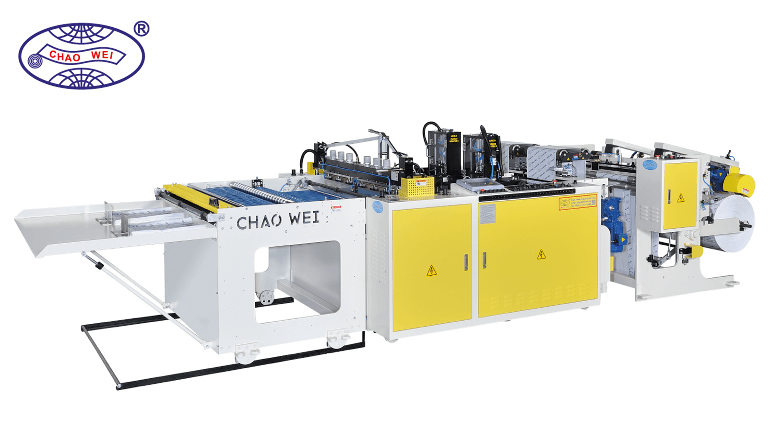

CHAO WEI: Bottom Sealing Bag Making Machine With Flying Knife System By Servo Motors Control

Plastic bag making machine CW-1200FK-SV/CW-1400FK-SV is suitable for the production of 2 lines printed or non printed bottom sealed bags with or without D punch. This machine is equipped with 2 servo motors to control bag feeding individually, 2 photocells to catch printing on plastic film, 1 servo motor to control flying knife function and impulse wire sealing device to produce heavy duty bottom sealed bags. Moreover, it can also be equipped with German made E.P.C and in line hot D punch device to produce shopping bags or welcome bags.

Efficient and Customized Blow Molding Solutions by CHEN WAY Machinery

Blow Molding is a widely used Plastic Molding method, and there is a high global demand for Plastic Molding. CHEN WAY Machinery Co., Ltd. specializes in manufacturing Plastic Blow Molding machines and has been in the industry for over 30 years since its establishment in 1990. They have successfully integrated research and development with manufacturing, and their products have been marketed in multiple countries worldwide. With rich experience in customized production, CHEN WAY can tailor machines 100% to clients' needs to meet their efficiency and effectiveness requirements in the production process.

Meeting the challenge head-on! As the Chinese machine industry makes advancements, Taiwanese competitors meet the challenge with three major strategies.

As the application of plastics and rubber continues to expand, the Chinese see incredible growth potential and value in participating in the market. Both government and private companies in China have invested heavily on it, from adapting technology for production to quickly entering the market with a small-profit-margin and high-volume sales approach. In this context, how should Taiwan's machinery industry face the impact?