近期更新 立即订阅

TUNG YU Hydraulics will Meet You at TaipeiPLAS2022

In the post-epidemic era, companies are highly anticipating the recovery of international business, after four years of absence, TUNG YU will meet you again at the TaipeiPLAS2022 from September 27 to October 1 this year at the TaiNEX 1 Hall1. In response to the current energy transformation, carbon reduction, and zero issues, combined with green energy and industry 4.0, TUNG YU will exhibit the latest development of a full range of solutions.

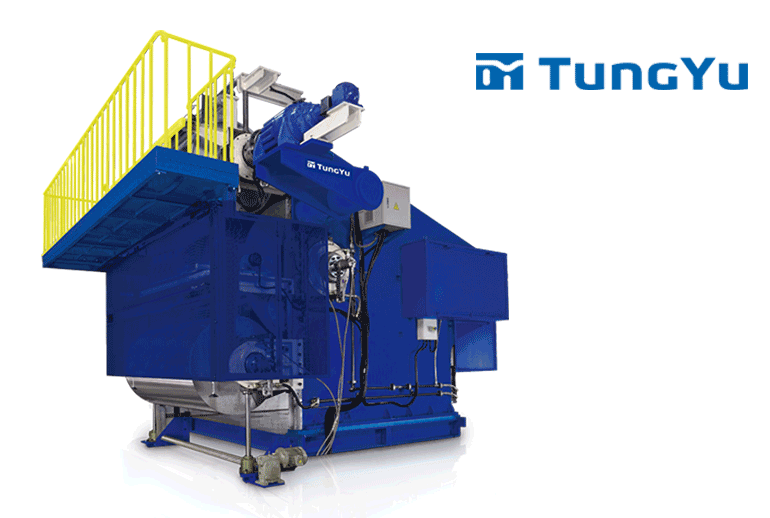

TungYu: Servo Press- Bringing the Power of Change to Create a Greener Future

In today's manufacturing industry, traditional hydraulic presses no longer meet the needs of production efficiency and the environment. With the spirit of continuous innovation and prioritizing customer needs, TUNG YU has developed a new servo press. Energy-saving and precise force application, using clean energy to increase production capacity, is an optimized high-quality solution.

TungYu: Horizontal Rubber Injection Molding Machine

How to save material and increase productivity simultaneously? Horizontal rubber injection molding machine can contribute to reduce material waste and optimize automation. Tung Yu makes our effort to serve the best solution for customer.

TUNG YU: Rotocure with CE Certificate

Continuous vulcanizing process provides high production efficiency and stable quality. Auto latching chuck for safety and promptly loading/unloading material shaft. Control system by PLC and HMI to easily and precisely set up temperature, pressure, speed and other production parameters.

TUNGYU- C Type Injection Molding Machine with Rotary Table

With C type configuration to have easy operation access. Rotary table design with two molds shifting to increase production efficiency. Feeding rupture detect to prevent process from rubber shortage. With external heating platen to maintain mold temperature.