Door lock Related Part

This product is made of PP+GF (Glass Fiber Reinforced Polypropylene), offering high strength, impact resistance, heat resistance, and low deformation rate, ensuring the stability and durability of large panels and main boards in high-load environments. It is designed for applications in structural support, industrial equipment, and automotive interior and exterior components, delivering excellent mechanical performance and long-term stability. Manufactured using a 1600-ton large injection molding machine, this product enables the production of large-sized, high-precision plastic components, ensuring superior structural rigidity and consistency to meet various large-component requirements. Additionally, compared to metal parts, PP+GF provides both high strength and lightweight advantages, effectively reducing product weight.

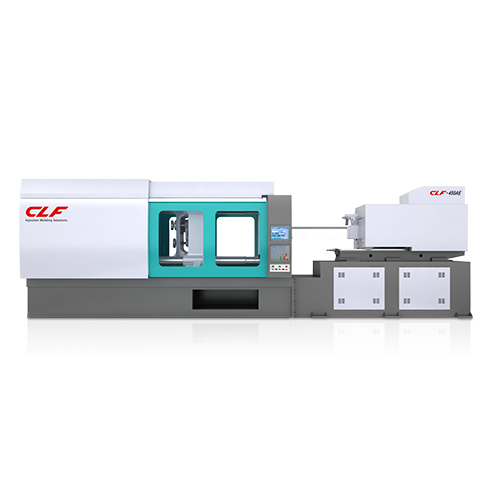

全电式塑胶射出成型机 - AE系列

产品分类 : 电动注塑机

秉持多年与日本OEM/ODM合作经验的全立发公司,累积无数技术,研发成功新一代全电式射出成型机,具备快速,精密,节能特性。采用德国西门子控制系统,比其他系统更具优势...

过胶头组(止逆阀组)

产品分类 : 阀门

过胶头组为射成形最重要的零件之一,我们提供适合各种塑料的过胶头组。根据不同的塑料开发并且量身订作各种形式的产品。不论是熔射、喷焊或是PVD镀层等各项之产品都有相当完整的配套。

DESIGN AND DEVELOPMENT PARTNER

产品分类 : 注塑模具

JDM / ODM SERVICES When bringing a new product to market or re-launching an existing product with new features, key success metrics are quality and timing t o market. Either or both may be negatively impacted if the design proves difficult to manufacture especially if there is a rapid demand for increased volume. A design partner who is well integrated with a full service manufacturing system knows how to minimize risk. Our design teams have executed numerous design-build projects for customers across a variety of industries on a global scale. We incorporate manufacturability, assembly and test principles into the EDI-early design stages involved of a product to assure seamless production. JDM/ODM services include : To use the PLM system to monitor the product life cycle management. Concept Development Mechanical Drawing Layout Documentation Verification Material Management & Sourcing Rapid Prototyping & Soft Tooling Initial Pilot Builds & DFM αTest /βTest/ Burn-in Tooling & molding in house Final Assembly Following the design phase of your product, we build prototypes to test the DFM manufacturablity and any industry compliances. Prototyping may occur multiple times at various points in the design and planning stages for a project. Once all the design and manufacturing issues are worked out, we can rapidly transition into full-scale production. Please visit our Contract Assembly page to learn more about our assembly facilities. OEM Our Original Equipment Manufacturer (OEM) service is responsible for designing and building a product according to a customer’s own specifications. Our service also includes & DFM,EDI,3D printer rapid prototype global distribution and returned product factory repair, which can greatly reduce customer’s overall production costs.