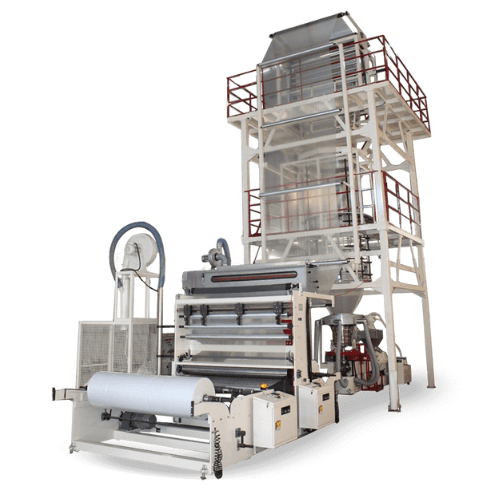

HR系列吹袋机

产品分类 : 吹膜挤出机

Film width available from 2000 ~ 4000mm, excellent for heavy-duty bags. Unique die head and air ring design to achieve stable bubble and better even thickness film and bag. Gear box uses high torque and enforced lubrication system. Automatic surface winder with uploading device. Oscillating haul-off. Blown film machine with oscillating haul-off system, built under the supervision of professional European engineers. AC inverter motor is designed for high production, quality and reliability to produce tubular film. High torque gear box with enforced lubrication system to minimize machine shutdown time. Good mixing performance of screw and barrel results in homogeneity and high output. Oscillating haul-off unit allows minimum web tension that eliminates wrinkle or bulge problem. High volume air ring is designed for ideal cooling efficiency.

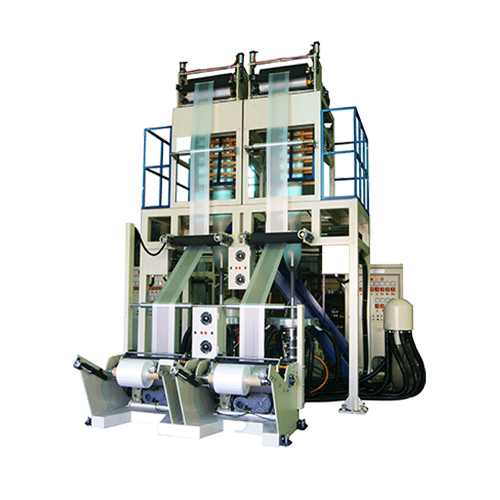

LDPE超高速吹膜机

产品分类 : 吹膜挤出机

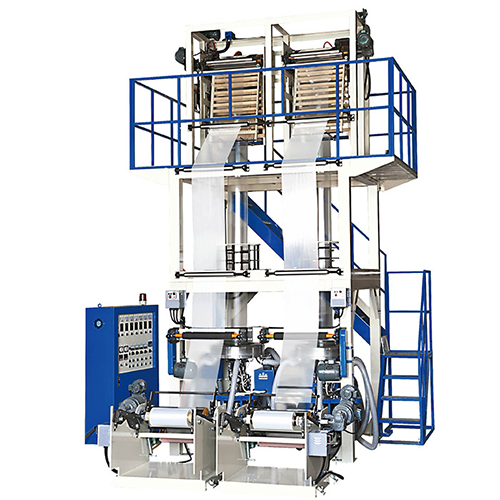

HDPE High Speed Mono Layer Blown Film Machine

产品分类 : 吹膜挤出机

Application: T-shirt bags, shopping bags, garbage bags, mattress cover, laundry bags etc. Suitable material: HDPE / MDPE / HDPE+LLDPE Film layer: 1 layer Screw L/D ratio: 30:1 Direct-connection design gearbox. PID+SCR temperature controller. ABB or HITACHI inverter. Gusset device.

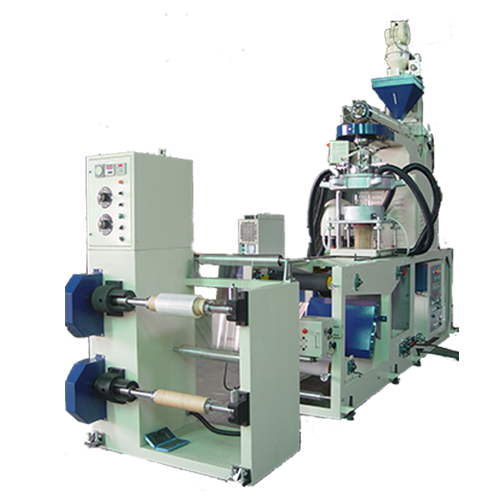

高速单层膜双膜头吹袋机

产品分类 : 吹膜挤出机

This two-head blown film machine line can produce 2 film rolls of the same width at the same time, and the production capacity is thus comparatively higher than models with only one die head. Thanks to the twin-head design, it not only occupies less space but also consumes less energy, which offers an economical solution for producing plastic bags of smaller width.

HDPE 单层系列吹膜生产线

产品分类 : 吹膜挤出机

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

三层共挤FFS重包装吹膜机

产品分类 : 吹膜挤出机

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.