PET拉伸吹瓶机系列-LM系列

产品分类 : 自动吹瓶机

全自动PET吹瓶机LM系列配有高速精密吹瓶阀,将空气回收转换为压力操作将减少空气消耗。从料斗转移到解扰器的瓶坯,按顺序自动输送到单个通道。缩短加热间距以减少能量浪费并提高加热效率。全自动PET吹瓶机LM系列采用连续集中加热方式,冷却坡道和吹气装置,有效隔离瓶胚颈部,避免瓶胚颈部因过热而变形。

PET吹瓶机系列-TEM08S2-88

产品分类 : 自动吹瓶机

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

PET吹瓶机系列-TEM0S82

产品分类 : 自动吹瓶机

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. ● The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. ● Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. ● The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. ● Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. ● With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. ● Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. ● The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. ● Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

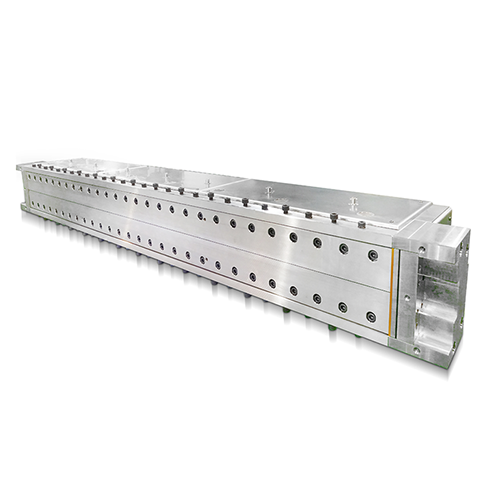

熔喷模具

产品分类 : 挤压模/模头

SUITABLE AVAILABLE FOR POLYMERS INCLUDING PET And PP High processing precision. Internal heating with heating rod, external heating with heating board, temperature control by heating oil cycle to ensure products of good uniformity. Meltblown filter in continuous and automated production to cut production losses more than 35%, cu costs, reliable product quality. Cut production materials consumption sharply. Featuring high yield, low power consumption, low loss, easy operation. Integrated meltblown Extrusion Die. Integrated meltblown Extrusion Die featuring precision aperture, good consistency and without maintenance wear out. Improved meltblown fiber quality and uniformity, improved product quality. Improved Extrusion Die life cycle and life span. Reduced Extrusion Die change operating time, cut maintenance cost and power consumption. Installation capacity down 30 ~ 40 KW. Cut production costs sharply.

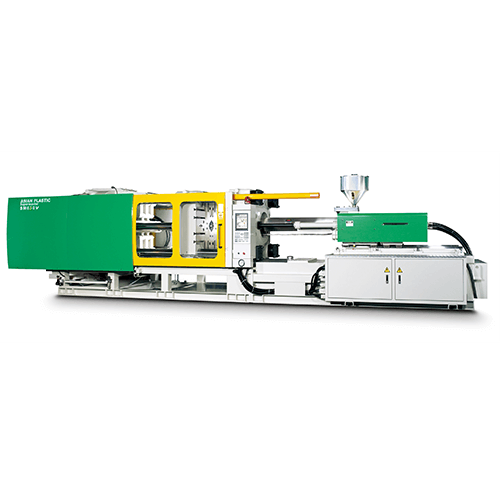

大型曲肘式伺服节能射出成型机

产品分类 : 卧式注塑机

• 超大的柱内距与容模量,固定板和活动板采有限元素法(Finite Element Analysis) 分析设计,以确保机械的强度及刚性。 • 采用双射移油缸可达到正确的模具对心效果,并可确保于高速高压射出时射嘴不会漏料。 • 线性滑轨射胶系统,减低机械耗损及背压产生,使产品射出更为精确。 • 采用BOSCH快速比例压力速度阀,此阀本身带有位置反馈,以及加装压力传感器,使得控制器所下达指令能够迅速反应回馈,达到敏捷精准的控制需求。

高精度油压截断冲床机CSS-607

产品分类 : 发泡机械

机身结构使用特殊钢料造型、耐冲压、永保平面度、冲头与滑块一体成型、高耐磨、强度特性、冲压稳定、延长刀模寿命、刀具可使用雷射刀、冲床冲模均可、产品无须边、各角度鲜明。吹料装置更可配合机械动作,一冲一吹,把斩后成品自动吹上,取料更方便、安全,加上万能沟底盘;锁模方便、迅速。并配置定点式脚踏开关等等,皆是展现高度成熟、专业工业设计取向。半自动刀模设定,操作易上手,又安全。

高精度四柱式油压裁断机CSS-603

产品分类 : 切割机

本机由压系统采用先进而耐用的特殊回路以及稳定性高的电控系统,可达超水准的效能。上下冲压行程由四大钢柱代替滑轨,前后送料采用精密线性轨道。机械启动后,低噪音、动作敏捷、轻巧,利于楼层厂房设计。有高度精度的裁斩深浅(微调)刻画调整器,精度容许值0.008mm。特殊平面钢板,代替传统式钻板,永久不磨损,刀具使用寿命长,永保锐利,提高工作效率。加工物件可全断及半断,背胶式物件亦可使用,产品无须边。可选购加装自动冷却系统及全自动裁断深浅装置。本机有安全防护装置,可确保人机安全。高精度的机体结构,可作全断及半断加工。上下冲压行程采用四柱高刚性导柱,送料机构采用线性轨道。两断式压力控制,动作轻巧,低噪音,适合楼层厂房使用。自动调刀机构,依设定自动调整,精度0.01mm(选配0.001mm)。高精度德国钢版,耐用度高,永不磨损。本机采用先进且耐用的油压系统及电控回路。安全防护装置,确保人员安全(可选配CE架构)。

高速曲肘式伺服节能射出成型机 (TSV 系列)

产品分类 : 液压夹模注塑机

特快锁模系统,采用油压差动回路,提高速度达60﹪以上,缩短周期,节省能源。 特殊无给油自润模板滑片,耐磨耐压,耐用性久。 自润铜司曲肘机构,确保机器之精度,可防止曲肘磨损。 采用BOSCH快速比例压力速度阀,此阀带有位置反馈,能够迅速反应回馈,达到敏捷精准的控制需求。 适用成型精密度高、薄壳成品之塑胶制品。 (成品厚度1 ㎜ L/t大于200) 蓄压器为选配装置。

全电式连续式中空成型机

产品分类 : 电动中空成型机

Servo Motor: Clamping Unit/Carrier Moving/Blow Pin/Parison Control Application: For Foods And Medical Or Special Application