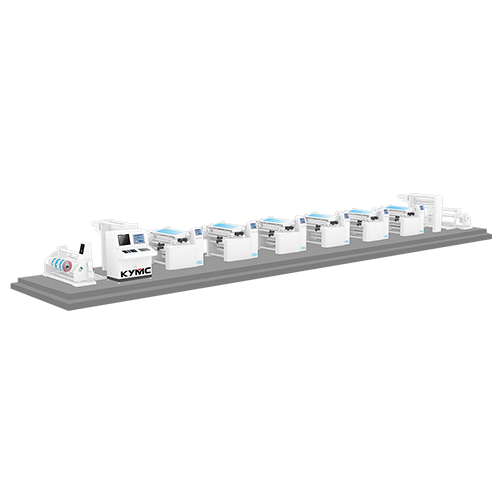

Flexojet -The Advance CNC Deck Control Press

产品分类 : 柔版印刷机

The Flexojet is a geared press but equipped with servo motors at the print deck to allow for print precision. The press provides excellent print quality at a decent press speed. If you are looking for a lightweight solution but with advance CNC printing deck controls, this is the press for you to customize.

笔类样品专用热转印膜

产品分类 : 薄膜

各类塑胶制品、布丁桶、容器、金属外壳、家用品、文具用品、礼品…等多项商品。具有直接印刷无法达成的多项功能,利用转印膜与转印机将精美图案转到产品上,适用各种材质,可提升产品的附加价值,降低成本,增加利润。

Bottle Filling Machine

产品分类 : 贴标机

FEATURES : 1. Made of SUS#304 corrosion resistant stainless steel and aluminum alloy 2. Filling volume and speed can be adjusted easily PLC control system with HMI touch panel for easy management 3. Memory storage of 15 to 20 sets for future usage 4. Ball-valve shut-off nozzle prevents liquid from dripping down 5. Dipping nozzles can prevent spillage and diminish bubbles 6. Capacity depends on filling nozzles, product and volume. 7. Machine is customized 4 - 12 filling nozzles. 8. It can be optional combined with the capping machine, labeling machine, shrink machine… 9. Piston pump filler is standard equipment, servo filler is optional. APPLICATIONS : Shampoo, Engine oil, Motor oil, Hair condition, Lubricant, Water, Sauce and other liquid or paste products …..etc..

TFVF Series

产品分类 : 指示器和传感器

三层共挤FFS重包装吹膜机

产品分类 : 吹膜挤出机

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.

PITAC Nucleating-agent masterbatch

产品分类 : 色母粒

PITAC Nucleating-agent masterbatch for PP/PE/PS Foam application

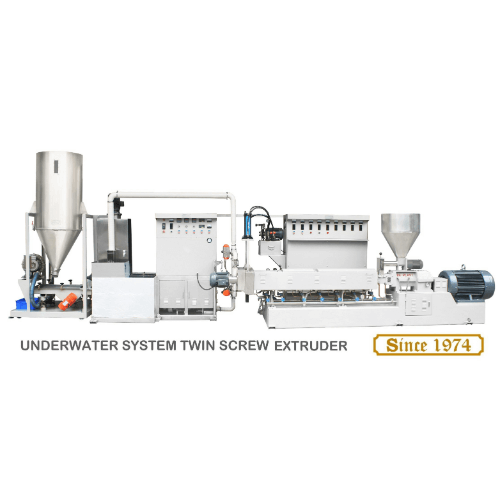

Extruder Machine

产品分类 : 塑料造粒机

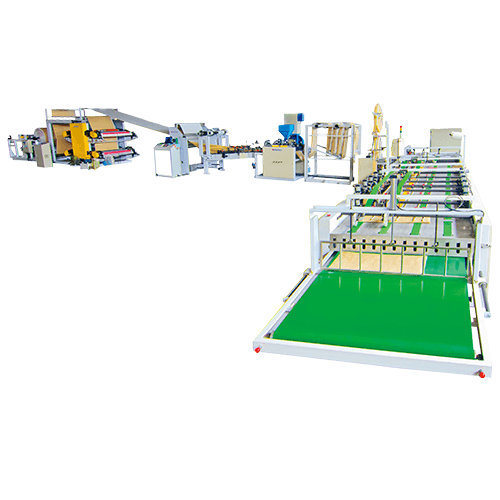

ABA三层共挤吹膜机

产品分类 : 共挤吹膜机

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

AEVK Series

产品分类 : 指示器和传感器

Moduflex-The Multi-Combination Modular Press

产品分类 : 柔版印刷机

The Moduflex is a gearless press that provides fast register setup ad tighter register tolerances. The press is able to combine with inline gravure, inline flexo, offset, die cutting sheet cutters and has a rotary screen. The press is suited for both mid and wide web application. If you are looking to integrate different production line processes together and with the highest flexibility, this is the press for you to customize

CONTRACT ASSEMBLY

Our Electronic Manufacturing Service (EMS) is used to Co- design, test, manufacture, distribute and provide repair services for electronic components and assemblies for Original Equipment Manufacturers. We have provided Co- design engineering and contract EMS for the consumer electronics, industrial, medical, military and telecommunications markets. We specialize in a variety of contract assembly levels from high volume, complex electro-mechanical assembly & testing to small volume, conceptual prototype runs. For small to medium device assembly, we utilize a cost savings system of mobile workstations and conveyors that can be quickly grouped into private and secure assembly cells. MANUFACTURING CAPABILITIES Electromechanical Assembly Subassembly and/or Final Product Assembly RoHS Compliant Assembly Lean Manufacturing PLM, MES, QMS, System Dedicated Program Management Functional and Post-Assembly Test Verification Material Procurement and Consigned Management FACILITIES 10,000 & 100,000 class clean rooms Flexible cell production system Mass management with Manufacturing Execution System (MES) 30,000 sq ft floor space with room for expansion Large, medium or small minimum order quantity (MOQ) HR expertise to maintain qualified production workers 24/7 operations SUPPLY CHAIN MANAGEMENT SERVICES YOMURA TECHNOLOGIES has many years of material & component sourcing experience and has direct relationships with factories around the world. Our office has been designed to coordinate quick quotes, provide constant updates and track all data needed to communicate with and expedite all client orders. This ensures a smooth transition from placement of orders to delivery. We understand our clients need to keep inventory levels low to control costs, yet still need to respond quickly for new orders to satisfy your customer demand. Clients can leverage our supply chain management expertise to receive volume quality products without high inventory risk. By customizing our stocking and logistics programs to meet your production needs we can reduce your material inventory during all stages of development from prototypes all the way through high volume production orders. TEST ENGINEERING Our Test Engineering department is staffed with experienced engineers and technicians who excel at working with customers to develop methodologies and design fixtures to reduce overall manufacturing costs, improve production yields, identify failures early, support root cause analysis, and assist design engineering with test analysis. Yomura has more than15 years waterproof IP68 test. REWORK SERVICES Sometimes rework of existing product assemblies is necessary to fix a design flaw, upgrade an assembly with a new components, or simply to find a cost down solution. Our rework specialists assure that resulting assemblies will meet the highest quality standards. CERTIFICATIONS QUALITY SYSTEM AS9100 / ISO 9001 / ISO 14001 / ISO 13485 / TS 16949 / UL Compliant / FDA / MFi

Master-batch-Feeder

产品分类 : 进料器

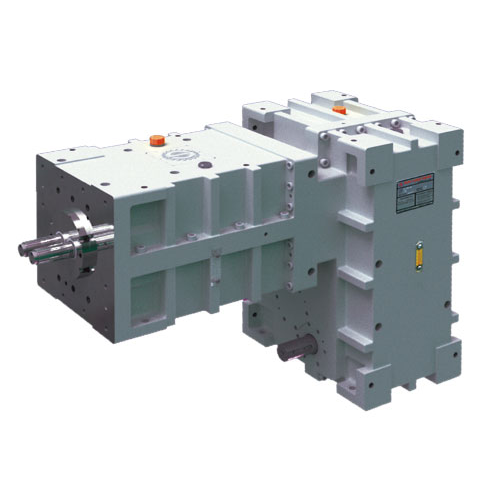

异向平双螺杆押出机齿轮箱

产品分类 : 变速箱

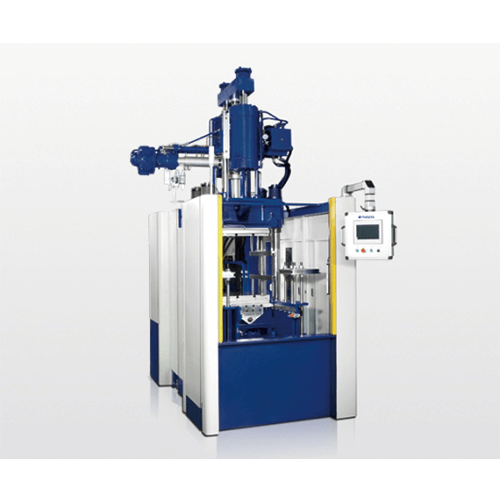

J型机构橡胶射出成型机

产品分类 : 制鞋机

●备料简单容易,不须秤重或考虑产品外型。 ●胶料经螺杆射出及保温控温之预热过程,有效缩短成品硫化时间、提高生产效率。 ●采用流道充填模头方式,针对形状复杂成品亦能轻易成型。 ●搭配模具之设计及定量射出控制,可大幅改善无效毛边、节省工时成本。 ●立式夹模机构,方便含骨架工件放置。

塑胶采光浪板- L1

聚碳酸酯角浪板是一个具有优异的耐冲击性,透明性和高透光度的高聚合物。其优良的机械性能、热性能和电气性能使其在建筑施工、景观、农牧业、DIY项目或旨在提高采光日照的任何建案中,皆为优良的材料。

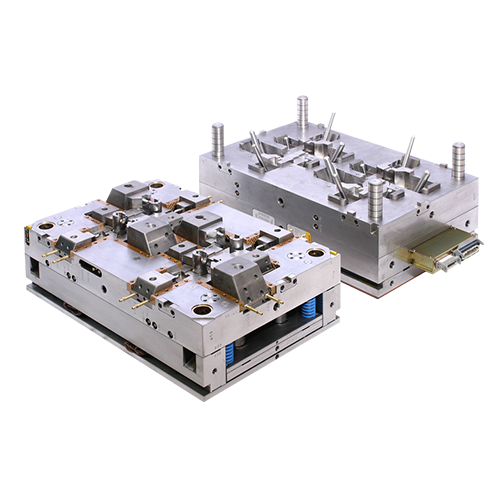

Hot plate heating type forming tools

产品分类 : 热成型模具

Hot plate heating type forming molds is mainly for producing OPS products like containers, trays, and lids......etc. The post-treatment process is required for continuous trimming.

Inline Coating & Lamination Application-The coating & lamination with maximum efficiency

产品分类 : 工业复合机

Inline Coating & Lamination Application (The coating & lamination with maximum efficiency) The main concept of inline coating application is to simplify the complete production process by integrating the printing press with the coating and lamination application unit. The inline coating units can include Reverse Gravure or Direct Gravure / Flexo Coating or Semi-Flexo Coating / Waxer or Hotmelt (Coating/Lamination). It can save unnecessary wastage during the production and increase production efficiency. If you are looking for suitable inline coating or lamination integration, this is the unit for you to customize. KYMC