内曲肘塑胶射出成型机

产品分类 : 卧式注塑机

CNT 系列是第一代傳統機台的延伸指標。透過不斷的研發、改進、成長,締造CNT 系列擁有更高效率、更佳穩定的性能。為迎合更多客戶不同的需求, CNT 系列除了擁有標準型,更有昇級型的加強設計,譬如CNT-A 〈快速射出機種〉、 CNT-C 〈全閉迴路高應答高速射出成型機種〉、 CNT -S/SD( 高壓高速高剛性機種) 、 CNT 電木機和三迴路機種等。

OVER INJECTION MOLD

产品分类 : 注塑模具

Over Molding is the process where one material is precision molded over another material, usually rubber (TPE) over plastic, for visual or ergonomic appeal. Very often when the design requires ” soft touch” or waterproofing (IP68), over molding is the manufacturing process that we will use. For over molding success, knowledge of material compatibility is crucial. Our extensive expertise in this field helps assure your end part will have the strong end-application bond and performance that your product success demands. Insert molding can also be combined with over molding using parts made of aluminum, brass, stainless steel, copper, plastic and more.

PE材质专用热转印膜

产品分类 : 薄膜

各种PE塑料制品都可以使用热转印,一些复合材料如HDPE和LDPE,也可以使用,只要表面光滑平整,图案和产品就可以完美结合。热转印膜有许多直接印刷所没有的功能。使用热转印膜和热转印机将优雅的设计转移到产品上,使产品成为高价值的商品。它可以提高质量,降低成本,增加利润。

CONTRACT MOLD MANUFACTURE

产品分类 : 热流道系统

CONTRACT MOLD MANUFACTURE Yomura offers production molds that will be to customer’s facility or a manufacturing location designated. We manufacture molds for almost every major end market for plastics, like, housewares and delicate medical parts, aerospace parts, automotive parts or tiny parts for consumer electronics. All the molds are built to your specification, including type of steel, runner system, gate type, cavity materials and other features specified. Whenever the molds arrive at your facility, they can fit directly to your injection molding machines and are ready for production. ADVANTAGES Early involvement in design phase Ability to provide accurate and quick mold quote Low cost, quick build and high quality A price fully competitive with major mold makers around the global Long life-cycle and low maintenance Reliable delivery schedules Delivery of bug-free molds and ready for production as soon as arrival Complete integrated design and project management services Adapting the latest technology in design and advanced machine tools Ability to communicate quickly and efficiently, and easy to work with Close to superhighway, allowing for quick travel Service centers and international offices are available in major market countries Joint mold making operations with mold makers in other countries bring Yomura closer to the customers PROCESS FOR CONTRACT MOLD MANUFACTURE Customer supplies 3D CAD file to acquire quote Yomura starts the mold order process based on confirmation Yomura sends the 3D full mold design for your review and approval Yomura starts to build the injection mold upon approval Pilot and short production run after mold completion Sample approval Tooling delivery to location specified

SINGLE INJECTION MOLD

产品分类 : 注塑模具

Single Injection Molding is a standard process that YOMURA TECHNOLOGIES excels at. Our YangMei plant is equipped with a resin feeder system to increase yield rates for mass volume production. Material: TPR , PC, PC/ABS, ABS ADVANTAGES: Works with Complex Designs Has the Advantages of Both Plastic & Rubber Flexible & Soft Touch

三层共挤FFS重包装吹膜机

产品分类 : 吹膜挤出机

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.

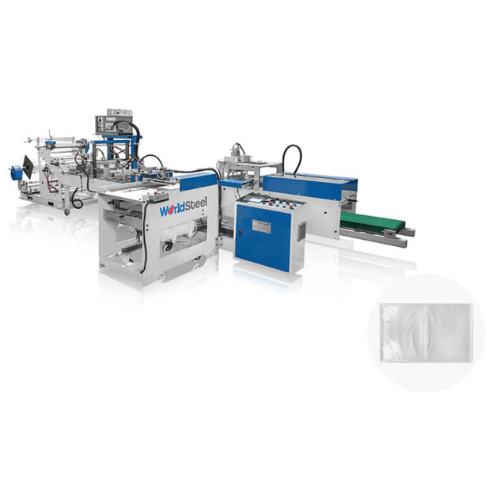

资料册全自动生产包装机

产品分类 : 制袋机按用途

目前资料册制程中,大多采用人力进行黏合包装,因应工业4.0生产自动化,开发资料册自动黏合机及资料册自动包装机,在资料册的制程中采用自动控制、自动调整装置,以取代人力,达到更稳定的生产品质,并在提升产值同时增加竞争力。 双重机台弹性配置 世钢独家研发机台结构创新设计,提供资料册、资料袋产线更灵活的运用,可以单机使用,也可以配置自动包装机,从入料到成品,可在全自动的生产线上完成,节省人工成本,增加产能。 资料册生产制袋机 全自动伺服马达控制封切机设计,可高速生产及黏合资料夹,搭配伺服马达电脑控制,订本位置准确不易跑位。智慧系统在运转过程中全程监控,发现异常时立即停机警示,提供高效又安全的资料册内页制袋机及资料册黏合生产线。 资料册全自动生产及包装专用机 所有工序由程式自动化控制,可以透过操控面板进行设定,在资料册、资料袋大批量产前,只需要在操控面板上设定参数,即可一键启动,一次完成多道工序 ,自动化设定后可降低人力操作,自动输送、点数功能,有效节省人力,提升整厂自动化整合。

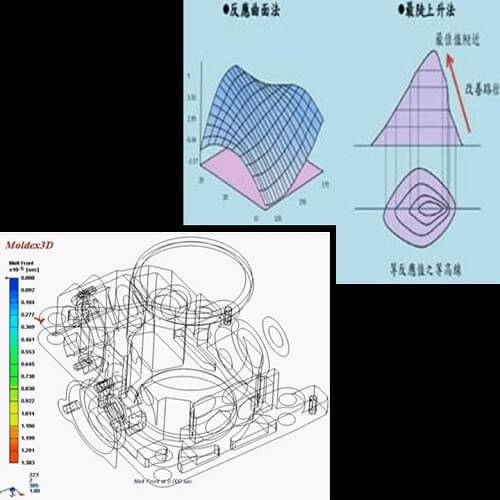

PROCESS OPTIMIZATION

产品分类 : 注塑模具

In-Mold Decoration (IMD) is an efficient, durable and cost effective technique for printing, painting, and forming plastic decorations. However, a large number of parameters involved IMD manufacturing processes and the complex relationship between these parameters make the determination of the optimal parameter setting a challenging task. This paper proposes a systematic framework integrating Response Surface Methodology (RSM) and logistic regression to improve the yield of IMD manufacturing process. The integrated framework becomes easy to identify the optimal parameter setting,saving a great deal of time and money in the manufacturing process. On the empirical study in collaboration with Yomura, the proposed framework shows the significant result from 10% to 87.5% validating the viability of the proposed framework in real setting. (Key words: IMD, In-Mold Decoration, Parameter Optimization, RSM, Response Surface Methodology, Logistic Regression) EXPERT ANALYTICAL SYSTEM Yomura Technologies employs state-of-the-art technologies to select materials, validate component designs, develop tool designs and optimize its processes, ensuring that innovative concepts are achievable at the lowest cost of production. (Keywords: Moldex3D, Moldflow, PowerMill Pro, CAD system)

Pressure Forming + Shape Cutting + Auto Counting Stacking SL-1220A + SL-520

产品分类 : 真空成型机

Flexible package solutions for various budgets and production needs. Fine processing competence fit for all standard and few specific plastics. Cold forming under high pressure load for high capacity and low cost. A cut of labor and waste via direct retrieval of plastic waste Low power consumption due to 30% saving energy and 40% compressed air cutting. A central control unit for easy operation and handy maintenance. • Rich experiences in package equipment with a tailor-made solution for you