LVDT 位移传感器

产品分类 : 指示器和传感器

差动变压器式位移传感器(LVDT)可广泛应用于航天航空、机械、建筑、纺织、铁路、煤炭、冶金、塑料、化工以及科研院校等国民经济各行各业,用来测量直线位移、伸长、振动、物体厚度、 膨胀等。 产品具有无滑动触点、 使用寿命长、安全可靠等特点。LVDT 具有优良的性能,采用方便的单电源 9~28V DC 供电,电子电路密封在不锈钢金属管内 , 可以在潮湿和灰尘等恶劣环境中工作 , 输出为标准的 0~5V 电压信号、4~20mA 电流信号、RS485 数字信号输出等。 LVDT 位移传感器有分体式、回弹式、气动式三种基本类型 , 并可依据客户要求量身定制。 分体式 LVDT 测量行程范围为 0~500mm, 防水 ,防尘 , 动态特性好 ; 回弹式 LVDT 测量行程范围为0~100mm, 接触探头采用耐磨镀铬硬质工具钢 ,气动式 LVDT 测量行程范围为 0~15mm, 工作气压 0.15~0.7MPa。

超负荷保护装置

产品分类 : 模具保护装置

FUNCTION Overload Protector is equipped in Press machine to check hydraulic pressure of cylinder inside the slider. If happen overload, the hydraulic pressure of cylinder will be released immediately within 3/1000 seconds. When happen overload, in order to protect the press and die, the press will stop working immediately after receiving the signal from limit switch. After happen overload, the air will drive hydraulic pump to supply normal working pressure immediately and the press can work normal. It has pressure control valve inside of overload protector, which can adjust hydraulic pressure automatically and eliminate the impact of rising pressure (which cause by oil temperature rise) in pressing process. May select different types of components and control units base on the different types and specifications of press machines.

高精度卷对卷自动送料裁断机TRC-350SP

产品分类 : 发泡机械

装轴同步送料机构: 双轴同步送料提高了产出速度及良率。优越且安定的下死点精度: 采用了矗霖特有之专利下死点机构,重复定位精度+-0.005mm。高精度深度调整机构: 采用高精度机构,微调精度可达0.01mm(0.001mm为选配)。高效率增压回路: 较传统回路减少了30%以上之电力消耗。光学材料对应: 可依照材料之特性做专用之搬送系统。独特的材料搬送机构: 高稳定性之伺服控制系统,不会污染及刮伤材料。自动润滑机能: 全机采用自动润滑机构,减少日常保养的工作。废料收卷机构: 裁断加工后之废料自动收卷,节省空间,提高作业性。

EXTRUDER FOR PVC/TPO SOFT FILM

Fruitive International Co. helps consult and design different types of PVC / TPO soft products extrusion line for customers and suitable for a variety of PVC / TPO soft products production. It is applied to products such as PVC tablecloth, shower curtain, tiles backing, transparent film car decorative, flloring, TPO tablecloth, printed film and so on. The extruder and calender unit that consists of rollers is also the core equipment of a production line. Hence, this is important when choosing the right products. We always make every effort to assist our clients to select the requested products in regarding to some technical aspects such as length and diameter ratio of the extruder, the width and the material of the calendar roller with the maximum capacity in order to meet the aimed production capacity and product demands. We achieve making the best thickness contribution by adopting the technology of moving rollers, roll bending, and other means. It is also an option to equip the most up-to-date full automatic control as well as the thickness monitor on our calenders.

尼龙 66 工程塑料 - NB1200GH50

产品分类 : PA(聚酰胺)/尼龙

50%玻璃纤维增强(本色-低翘曲、高刚性、高耐冲击) 应用说明:手工具、电动工具、园艺工具用,汽车、机车、脚踏车零组件用,运动器材零组件用,电子、电器外壳及零组件用,O.A.办公室零组件用,水资材用,医疗复健器材。

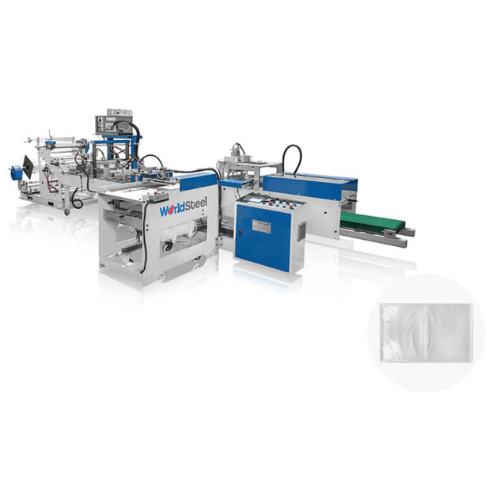

资料册全自动生产包装机

产品分类 : 制袋机按用途

目前资料册制程中,大多采用人力进行黏合包装,因应工业4.0生产自动化,开发资料册自动黏合机及资料册自动包装机,在资料册的制程中采用自动控制、自动调整装置,以取代人力,达到更稳定的生产品质,并在提升产值同时增加竞争力。 双重机台弹性配置 世钢独家研发机台结构创新设计,提供资料册、资料袋产线更灵活的运用,可以单机使用,也可以配置自动包装机,从入料到成品,可在全自动的生产线上完成,节省人工成本,增加产能。 资料册生产制袋机 全自动伺服马达控制封切机设计,可高速生产及黏合资料夹,搭配伺服马达电脑控制,订本位置准确不易跑位。智慧系统在运转过程中全程监控,发现异常时立即停机警示,提供高效又安全的资料册内页制袋机及资料册黏合生产线。 资料册全自动生产及包装专用机 所有工序由程式自动化控制,可以透过操控面板进行设定,在资料册、资料袋大批量产前,只需要在操控面板上设定参数,即可一键启动,一次完成多道工序 ,自动化设定后可降低人力操作,自动输送、点数功能,有效节省人力,提升整厂自动化整合。

Utraflex / Utraflex-H-The UV-LED press

产品分类 : 柔版印刷机

The Ultraflex press is a UV-LED central impression press to provide high quality print with high opacity. At the same time Ultraflex press is an ecofriendly solution as UV-LED application does not emit VOCs. The Ultraflex-H is a hybrid press that integrates 3 technologies, the UV-LED ink application, solvent/water-based ink application and the central impression (CI). The Ultraflex-H enables you to take advantage of the UV-LED application but at the same time draw back to the solvent based or water-based print stations when needed If you are looking for a flexible, cost effective and production efficient press, the Ultraflex series is the press for you to customize.

INSERT INJECTION MOLD

产品分类 : 注塑模具

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

尼龙 6 工程塑胶 - NAH1200G20

产品分类 : PA(聚酰胺)/尼龙

20%玻璃纤维增强 (本色-超韧耐冲击) 应用说明:手工具、电动工具、园艺工具用,汽车、机车、脚踏车零组件用,运动器材零组件用,电子、电器外壳及零组件用,O.A.办公室零组件用,水资材用,医疗复健器材。

Primary Packaging–General - Closing - AC-80

产品分类 : 旋盖机

The container cap closing processor is capable to be applied for both plastic screw caps and ROPP sealing caps in one machine by changing capping system components.

三层共挤FFS重包装吹膜机

产品分类 : 吹膜挤出机

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.