OPP/BOPP Labeling Machine For Square & Round Bottle -Automatic High Speed

产品分类 : 贴标机

1. Application for labeling round and square shape containers. 2. Fully automatic rotary operation for 330ml-4000ml bottles.(with certain change of parts). 3. Machine frame made of stainless steel 304. 4. PLC electronic control, touch screen monitor and electronic speed control(frequency inverter). 5. With a star-wheel carrying containers firmly while dispensing , provide stable dispensing performance under high-speed operation. 6. Use servo motor to synchronously tracks label supply, label cutting and use specially designed vacuum drum to ensure precise labeling. 7. Three-phase PLC and AC variable control with a synchronized tracking and control system to maintain label cutting accuracy in different running speed. 8. Centralized lubrication system for easy maintenance. 9. Detecting in feed situation with sensor, automatically adjust labeling speed according to feeding situation of production line, making production line coherent. 10. System safety device: when malfunctions such as irregular torques and abnormal feeding occur, machine will automatically stop for operation safety and machine durability. 11. Automatic label proofread system controller made in Germany. 12. Automatic speed self adjustment to contact other machine.

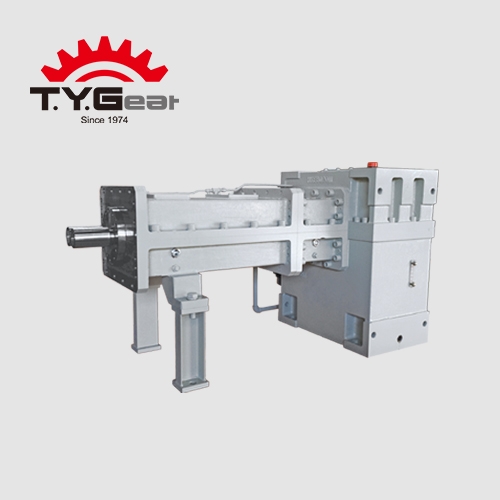

同向旋转-双螺杆挤出机

产品分类 : 变速箱

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus with flange which could suffer high pressure to absorb the axial pressure caused by the extruders. (2) Following AGMA criterion to design gear elements which adopts low-carbon alloy steel bar materials(Normally, it is SCM420 or same level). The precision reaches AGMA 10 level after carburization heat treatment then treating gear surface grinding to make sure low noise, low abrasion and high efficiency during operation. (3) #294 Series Thrust bearing with axial self-aligning roller type & muti-row stacked tandem bearing package to have advantage of low friction heavy axial load capacity.

3RT开模+脱模汽缸橡矽胶真空热压成型机/ VCC-D3J

产品分类 : 压缩成型机

脱模气缸开模时脱模气缸伸入使上模和中、下模分离。真空能力真空度高,采平均抽法,可便品稳定,提高品质及产能。开模设计3RT 架构特点在于超越一般传统前顶式掀模,可用于三层或四层模具

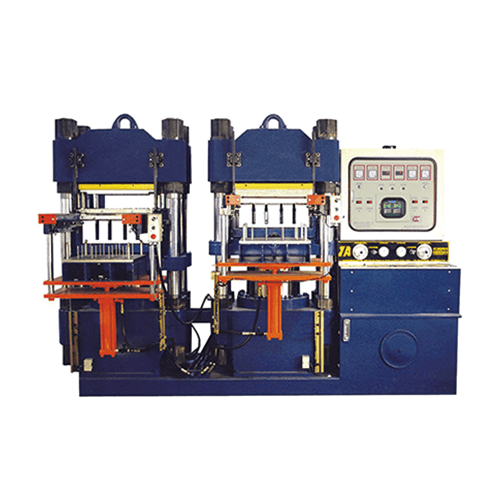

2RT开模橡矽胶热压成型机/ HCC_D2

产品分类 : 压缩成型机

产品特性开模设计2RT 架构特点在于超越一般传统前顶式掀模,可用于二层或三层模具之特殊功能,具有掀模及中层模具个别顶出之设计。此掀模功能具有分段掀模、分段中模顶出、连续掀模及中模顶出之软体设计,可依操作需求作调整。

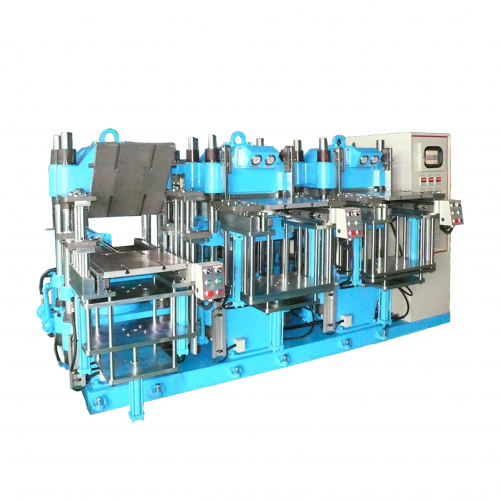

4站式2RT开模橡矽胶真空热压成型机/VCC-F2

产品分类 : 压缩成型机

产品特性真空能力真空度高,采平均抽法,可便品稳定,提高品质及产能。开模设计2RT 架构特点在于超越一般传统前顶式掀模,可用于二层或三层模具之特殊功能,具有掀模及中层模具个别顶出之设计。此掀模功能具有分段掀模、分段中模顶出、连续掀模及中模顶出之软体设计,可依操作需求作调整。

专利轨道开模橡矽胶热压成型机/ HCC-DP

产品分类 : 压缩成型机

产品特性开模设计专利设计之新型轨道开模,掀模角度可达90度,方便人员操作。换模具时,不需将轨道开模座卸下,即可轻松完成。大幅提升工作效率及安全性。掀模设计特殊掀模机构设计,耐用寿命长,出入模安静、快速、平稳。

3站式3RT开模橡矽胶热压成型机/HCC-T3

产品分类 : 压缩成型机

Features This type of machine is multi-functional, because it is suitable to be used for top opening triple or four molds. Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously. Slow speed of mold calibration is provided to make the calibration safer and more accurate. Molds can be precisely positioned. A 100% safety design for positioning is available to prevent molds from damage. The speed to open/close the mold is adjustable. It is very accurate and reliable.

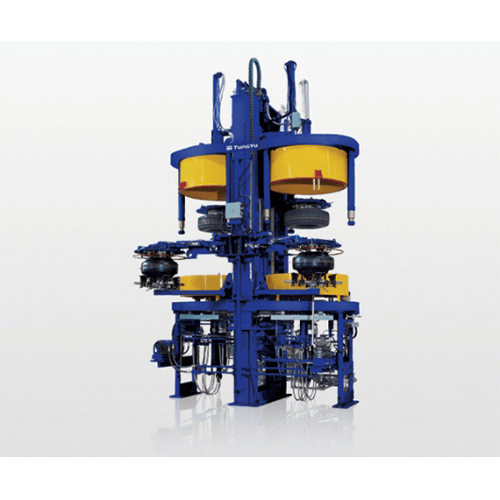

51型轮胎硫化成型机

产品分类 : 橡胶硫化/硫化机

●油压单元可搭配伺服马达,降低能源消耗,并稳定产品质量,提高工作效率。 ●挟胎机械手及自动卸胎定位精准,提升缓冲效果。 ●热板采特殊回路设计,提高均温效果,可长时间保持温度稳定,降低产品不良率。 ●后充式装置(选配):安装于主机后方,实行自动控制和续化运行,轮胎硫化后在受气体张力下进行冷却及定型,避免胎体变型,提高产品良率。