Secondary Packaging - Cartoning - CSC-50A

产品分类 : 装盒机

The cartoning equipment applies the vertical automatic production operation. The equipment is suitable for more types with medium capacity products

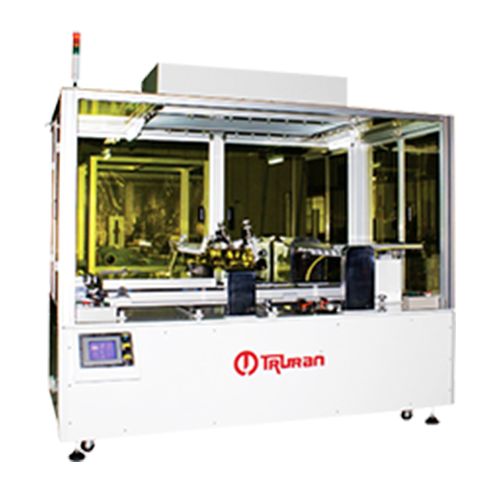

偏光板贴付机GFL-20

产品分类 : 淋膜机

High Rigid Body Design: Higher workpiece machining accuracy. More stabilized bonding range. Higher accuracy. Smooth Bonding Process: The bonding process has been carefully designed in providing safe interlocking and higher yield rate. Automatic Film Stripping Mechanism (Optional): Automatic bonding film stripping mechanism in providing stabilized action and higher efficiency. Patented Bonding Mechanism: Special bonding mechanism is designed to achieve higher bonding accuracy and air bubble free effect.

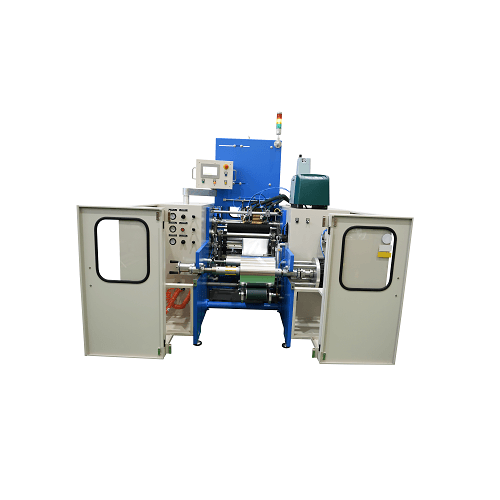

SIX SHAFTS TYPE AUTOMATIC ALUMINUM FOIL / CLING FILM REWINDER (AH-6S)

产品分类 : 分切机和复卷机

AH-6S, the six shaft type automatic rewinding machine. It's designed for rewind aluminum, PE and PVC cling film. The feeding press roller is carried with precise pressure manometer and regulating valve. Movements include automatic feeding material, automatic cutting and unloading the finished product. This model has automatic length correcting function. It can correct the margin of product length anytime. There are 2 type of mother roll width for AH-6S: from 250-450 mm, and from 300-500 mm. The product length is from 3-250 meters, the finished paper core's I.D. can be appointed within 25-38 mm. Users can choose to equip label sticker device and hot melt glue device with machine. They will make product more perfect. Stably fix the material on the paper core, neatly produce product with smooth edge. Machine brings you a huge benefit in the way you need. Welcome to consult machine with us. We will at your service.

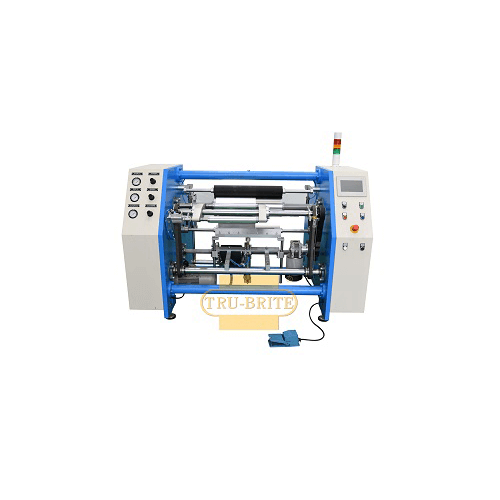

MULTIFUNCTION TWO-SHAFT TYPE SEMI-AUTOMATIC ALUMINUM FOIL & CLING FILM REWINDER (SRB-A-2S 20-50)

产品分类 : 分切机和复卷机

SRB-A-2S, the two shaft type semi-automatic, multiple functions rewinding machine Suitable for rewind aluminum foil and PE, PVC cling film. The mother roll available width is from 200-500 mm. The finished paper core’s I.D. is from 25-50 mm. This model is carried a brake system, controls the brake power accurately. Users can check the data of brake output and single product weight anytime. SRB-A-2S is able to set prior deceleration points of every speed level. Users only need to adjust rewinding speed afterwards. Machine will regulate deceleration points automatically by the settings. It has automatic functions of cutting and fixed length feeding. Users will thread the material onto paper core more convenient. The whole machine is combined of electronic control, carried with electric motor system; enable more precise and quicker shaft-changing movements. While finished rewinding process, the rewinding shaft will back off by itself. Users can switch to the automatic mode which start machine automatically after shafts are pressed down. Automatic cutting, automatic shaft-changing and shaft pressing, users just need to load & unload products after press start button. Welcome to consult machine with us. We will at your service.

上升-下降橡胶射出成型机

产品分类 : 橡胶注射成型机

产品特性射出量控制采高精密度光学尺设计,能准确的控制与计算射出量之大小。转射板设计具特殊的座进、座退功能,可使射嘴不死料。清料容易,品质稳定。安全设计备有高科技红外线安全电眼,并具有全自动警告系统及多重安全防护装置,可清楚掌握机台状况,确保安全。油路设计比压比流油路设计,稳定、安静、故障率低,两轴可同时操作。

PP Woven Bag Conversion Line - JLCSHM SERIES

For BOPP bag or lamination woven bag Automatic Handle-inserter & sewing Patents Design Future trends

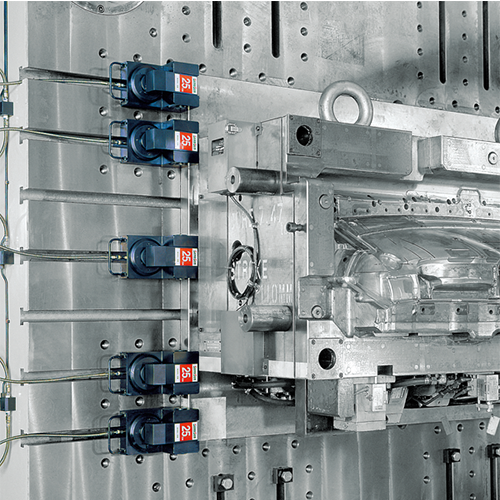

射出机、压铸机快速换模系统

产品分类 : 换模系统

It is an era for making high frequency mold change with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to apply Quick Mold Change System. SAFETY FUNCTION OF SYSTEM Each hydraulic circuit has the function of check and avoiding oil leaking. This system can add pressure automatically when the pressure reduction. Each hydraulic circuit has the function of inspection pressure and can be interlocked with the machine. It adopts the intersecting direction to clamp the mold. There are several functions to avoid operation error.

THS 850/950

产品分类 : 工业机器人

•真空夹具电路。 •自动模式微修改。 •自动堆垛/码垛。 •从模具的型芯/型腔侧取出零件。 •拒绝零件/报警/操作历史。 •站在模具上,等待外面的模具。 •错误的计数/分解历史/操作记录。