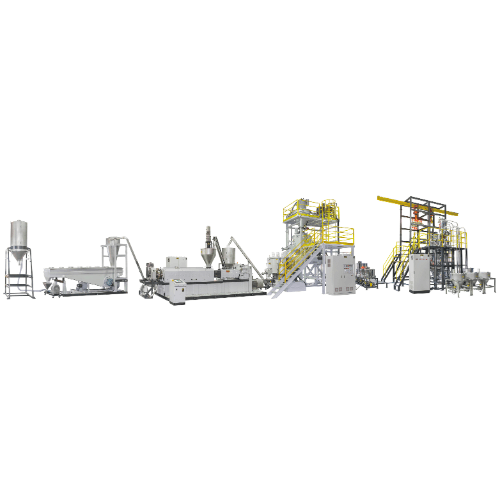

PVC Automatic Metering / Weighing / Conveying Pelletizing Extrusion Line | CK-DT

产品分类 : 双螺杆挤出机

CYKF has good reputation in PVC extrusion. Our CK-DT series Counter-rotating Twin Screw Extruder is especially designed for PVC. The available screw diameter is between 55 to 130mm. Thanks to our technical team put long term effort on this field which makes CYKF’s PVC extruder is competitive compared to other competitors. Our durable and high-efficient PVC extrusion pelletizing line is able to produce rigid PVC, soft PVC, medical grade PVC, UPVC, CPVC, and additives of foam or wood powders. We are pound to say the PVC extrusion line made by CYKF is no doubt the best choice for customers. Possible materials : UPVC, CPVC, Medical grade PVC, Soft PVC, Rigid PVC, Foam and wood powder additives.

Medical Grade PVC Pelletizing Extrusion Line | CK-DT

产品分类 : 双螺杆挤出机

CYKF has good reputation in PVC extrusion. Our CK-DT Counter-rotating Twin Screw Extruder is especially designed for PVC production; the available screw diameter is between 55 to 130mm. Thanks to our technical team put long term effort on PVC extrusion technology which makes CYKF’s PVC extruder is competitive compared to other competitors. The high-efficient and durable PVC pelletizing machine can produce rigid PVC, soft PVC, medical grade PVC, UPVC, CPVC, and additives of foam or wood powders. It has outstanding performances that has earned highly praises from global customers.

医疗消毒袋制袋机

产品分类 : 塑料制袋机

1. Main drive AC motor + inverter control. 2. The Sterilized Pouch length is accurately controlled by servo motor incorporated with mark sensor for greatly upgrading the production speed. 3. Twin Rolls unwind stand suits for two layers of different materials and multi-line production which upgrades efficiency greatly. 4. Two sets of dancer-roller unit provide the stable feeding tension both upper and lower web. 5. Equipped with microprocessor PID temperature controllers provide the most accurate and fastest heating performance. 6. Equipped with two sets of shear knives for bag partition. 7. Micro computer control system.

Inspection Rewinding Machines INSPECT-SB

产品分类 : 分切机和复卷机

This double-side rewinding machine can do more serious inspection for the better quality, especially for packages of medical, cosmetics and some high-price food products. Integrated with automatic defect system, this machine can reach precise and continuous inspection to ensure zero defects.

Insert Injection Molding

Insert Injection Molding Technology is a manufacturing process that integrates pre-placed components, such as metal inserts, electronic parts, or other materials, into a plastic injection mold. During molding, molten plastic encapsulates the insert, creating a single, durable, and high-precision component. This technology enhances product strength, reduces assembly costs, and improves reliability, making it widely used in automotive, electronics, medical devices, and consumer products. By ensuring strong adhesion between plastic and inserted components, insert injection molding enables lightweight designs, enhanced durability, and improved performance in various applications. Key Advantages: Seamless integration of metal and plastic components Higher product strength and durability Cost-efficient by reducing assembly steps Customizable for complex geometries Enhanced precision and consistency Common Applications: Automotive Parts – Armrest trim panels, dashboard components, connectors Electronic Components – Connectors, circuit boards, protective casings Medical Devices – Surgical tools, sensor housings, implantable components Consumer Goods – Power tool grips, ergonomic handles, durable casings

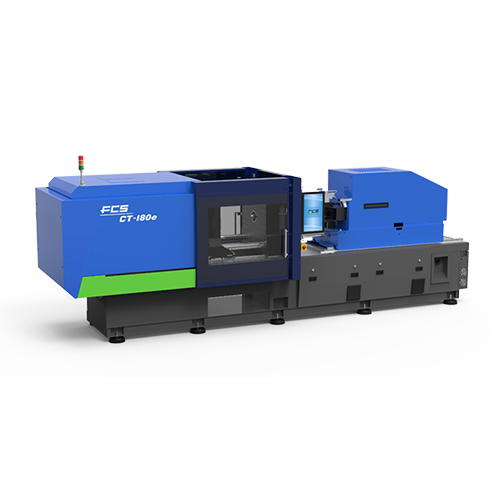

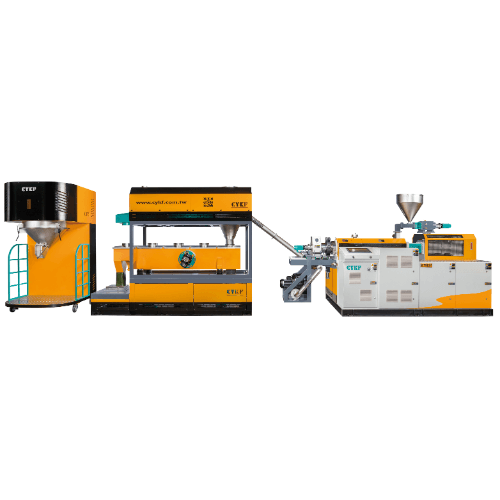

85-150 ton injection molding machine product

产品分类 : 注塑产品

This 85-150 ton injection molding machine is designed for high-precision plastic product manufacturing, including automotive components, electronic parts, appliance housings, medical devices, and consumer goods. Equipped with a high-efficiency servo-driven system, it ensures stable injection pressure and precise control, delivering superior molding quality. With a high-rigidity clamping structure and an optimized hydraulic system, this machine offers durability and operational efficiency. It supports various plastic materials (PP, PE, ABS, PC, PA, etc.) and can be customized with multi-stage injection units and robotic interfaces for full automation, reducing labor costs and increasing productivity. Ideal for OEM manufacturers, plastic molding factories, and precision molding industries, this model meets modern production demands with efficiency and precision.

Overmolding Injection Molding

Overmolding Injection Molding Technology is a multi-material molding process that combines two or more materials in a single mold to enhance structural integrity, comfort, and functionality. This process allows flexible materials (such as TPE, TPU, or silicone) to be molded over a rigid substrate (such as ABS, PC, or PA), providing superior grip, durability, and impact resistance. This technology is widely used in automotive, electronics, medical devices, and consumer products, particularly for components requiring ergonomic design, shock absorption, anti-slip surfaces, and sealing properties. Compared to traditional assembly methods, overmolding technology offers cost savings, improved structural integrity, and an enhanced product appearance and feel.